Troubleshooting is a crucial ability for electronics workers to recognise and resolve circuit problems. Understanding how to methodically analyse issues can save time and prevent costly expenses, whether you’re creating a new project or maintaining equipment that already exists.

This article will go over five useful approaches for debugging electronic circuits, ranging from examining parts and connections to employing sophisticated instruments like oscilloscopes. These procedures can help you fix even the most complicated problems and get your circuit operating again.

The Importance of Electronic Repair and Maintenance

Before delving into the techniques of troubleshooting, it is important to highlight the importance of electronic repair and maintenance. Here are the main benefits of electronic repair and maintenance:

- Prolonging the lifespan of devices, enhancing performance, and ensuring safety.

- Preventing costly breakdowns by maximising the utility of existing equipment.

- Helping maintain functionality.

- Keeping devices operational, reducing interruptions.

- Maintaining energy-saving features, leading to lower utility bills.

- Reducing waste and encouraging sustainability by maximising existing equipment.

In a world increasingly reliant on technology, understanding how to repair and maintain electronic systems is essential for both individuals and organisations, looking for more sustainable and efficient solutions.

Key Troubleshooting Tools

To start any troubleshooting project, it is important to have the right tools. Have a look at our list of several key tools to effectively troubleshoot electronics:

- Multimeter – for measuring voltage, current, and resistance.

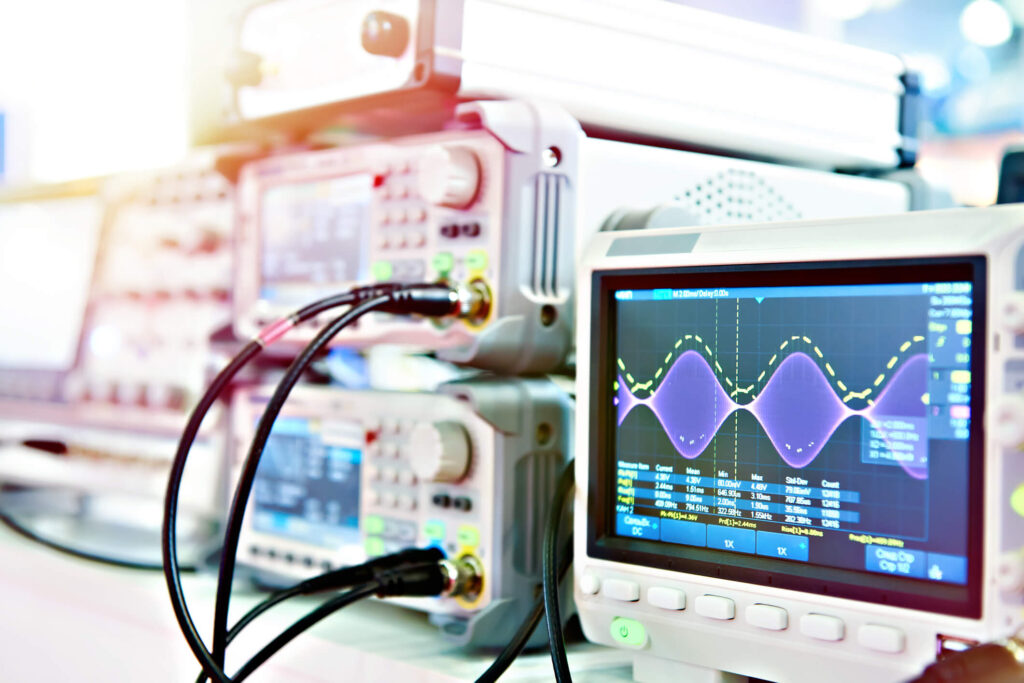

- Oscilloscope – for visualising signals and waveforms in a circuit.

- Soldering Iron – for assembling and reworking circuit connections.

- Continuity Tester – to check for breaks in circuits or connections.

- Power Supply – for safely powering circuits with adjustable voltage and current limits.

- Logic Probe/Analyser – for testing digital logic levels.

- Tweezers – for precise component handling.

These tools help diagnose, repair, and maintain electronic systems efficiently.

Five Practical Methods to Diagnose Electronics Circuits

1. Start with a Visual Inspection

Prior to turning on the circuit or utilising any tools, a careful visual examination might identify clear problems. Keep an eye out for anything that seems out of place, such as broken traces, loose wires, or burned components. Look for bulging capacitors and burnt-looking resistors. Clues can be found by using your senses; smell for burned regions or observe for abnormally hot spots. Many problems can be readily fixed with simple changes like tightening a slack wire or replacing a burnt resistor.

Key tips for visual inspection:

- Look for any broken or corroded solder joints.

- Check for short circuits or bridging of pins.

- Inspect capacitors for bulging or leaks, as these are common points of failure.

2. Verify the Power Supply

Checking to see if your circuit is receiving the right power after the visual inspection is over is the next step. A defective circuit can frequently be attributed to a problematic power supply. To make sure the voltage at the circuit’s power input points is at the necessary levels, measure it with a multimeter. Verify that any voltage regulators in the circuit are producing the appropriate voltage.

If the power supply is too high or too low, it can cause various components to behave unpredictably or fail. This step is critical because all components rely on consistent, stable power to function properly.

Steps to check power supply:

- Measure input voltage using a multimeter.

- Verify ground connections are properly established.

- Check for voltage drops across key points in the circuit.

3. Test Individual Components

If the power supply checks out, but the circuit is still malfunctioning, the issue might be with individual components. Using a multimeter, test resistors, capacitors, diodes, and transistors to ensure they are functioning within their specifications. Components like resistors can degrade over time, while capacitors can short-circuit or lose capacitance. Transistors may fail, leading to signal cutoffs or unexpected behaviour in the circuit.

When testing components:

- For resistors, ensure the resistance value matches the colour code or datasheet.

- Capacitors should not show a short circuit (except for certain special types like tantalum capacitors).

- Diodes and transistors should be tested for proper forward and reverse bias conditions.

4. Signal Tracing with an Oscilloscope

The next step is to trace signals across the circuit if simple testing isn’t able to identify the issue. Track the input and output signals at critical circuit locations using an oscilloscope. This is particularly helpful for digital and analogue circuits where signal integrity and timing are essential. Examine the observed signal in relation to the datasheets or circuit design’s predicted behaviour.

By checking waveforms and voltage levels, you can often pinpoint where a signal is getting lost or altered, leading to a malfunction. This step is particularly important in diagnosing complex circuits like amplifiers, processors, or power supplies.

Steps for signal tracing:

- Connect the oscilloscope probes to key nodes in the circuit (e.g., inputs, outputs, and power rails).

- Compare the real-time waveform with the expected signal.

- Look for noise, unexpected drops, or distortions in the signal path.

5. Inspect and Repair Connections

Verifying all physical connections, such as solder joints, cables, and connectors, is the last stage. Over time, solder junctions may deteriorate or crack, particularly in circuits subjected to mechanical stress or vibration. “Cold joints,” another consequence of poor soldering, may cause sporadic connection or breakdown under load. Reflow any questionable junctions with a soldering iron to make sure they are securely bonded.

When working with connectors, make sure they are clean and properly seated. Unpredictable circuit performance might result from weak connections caused by corroded or broken connectors.

Key tips for inspecting connections:

- Look for dull or cracked solder joints and reflow with fresh solder if necessary.

- Ensure all components are securely connected to the board.

- Test wires for continuity using a multimeter.

Troubleshooting Precautions

Every task that involves using electricity carries some risk of electric shock or injury. Hence, it is important to take a few precautions before you begin; some safety and preventive steps must be done to prevent shocks against the live circuits. To avoid electric shocks, make sure the equipment is always unplugged and shut off before inspecting it. Capacitors should be securely discharged since they can hold a charge even after the power is cut off. Employ insulated instruments, including probes and screwdrivers, to reduce the possibility of unintentional shocks. When handling potentially dangerous materials, wear safety goggles and keep an eye out for high-voltage components. By following these precautions, you may help ensure a safe troubleshooting procedure.

Conclusion

Most problems in an electronic circuit can be thoroughly troubleshooted and repaired by following the right steps. Prior to going on to component testing and signal tracing, always start with the fundamentals, such as visual inspection and power checks. It is possible to restore complete functionality to your circuit by solving intricate issues with perseverance and meticulous examination.

Additionally, bear in mind that each project might require different troubleshooting steps to be taken, if you are still learning make sure you refer to your manual or teacher for further instructions, and always ensure safety measures are being taken.