Collaborative robots – or cobots as they are more commonly referred to – are a perfect example of human-robot interaction. The concept was first publicized back in 1996 by Michael Peshkin and J. Edward Colgate, two professors from Northwestern University in Illinois. Strategic Market Research estimates that by 2020 there were over 22,000 cobots in operation, and this number is rising rapidly (with a compound annual growth rate above 15% expected between now and 2028). Currently, cobots represent the fastest expanding segment in the global industrial robotics market, according to studies undertaken by Frost & Sullivan.

Cobots are designed to work alongside humans within a shared environment. This is in contrast to conventional industrial robots – which have to be fenced in or isolated, so as to ensure worker safety. Unlike their bulky, complex and expensive counterparts, they are usually compact, relatively lightweight and simple to operate. Most importantly, cobots are versatile and affordable, enabling companies of all sizes to realize the benefits associated with automation.

Cobots in Industry 5.0

Industry 5.0 envisions bringing back human workers to automated factory floors, and having them cooperate with robots in a way that will bring extra value to the production process. The objective of this will be to combine the experience and ability to adapt that humans inherently have with the efficiency and exactitude of robotic systems.

This is where cobots come in. Designed to work in conjunction with people, they are an ideal fit for the core principles of the next phase of industrial progression. In addition to being smaller (thereby posing less of a physical threat), cobots are equipped with advanced sensors and vision technologies. This enables them to detect any risk to people working in close proximity.

Safety is just one of the salient features of cobots though. They are also very easy to install and require only minimal programming expertise to operate. Because of their compactness, installation is simple. It is straightforward for units to be positioned in different sections of the workspace – making them highly versatile and applicable to various tasks.

Notable Use Cases

Cobots bring out the best of humans and machines – drawing on the cognitive skills of the former and the power and consistency of the latter. They are proving themselves to be advantageous to companies across a broad array of different industry sectors. Here are just a few of the success stories already witnessed.

- Machine Tending -Traditional machine tending usually needs the human operator to be confined solely to a specific machine, in order to cater for its requirements while carrying out the assigned task (grinding, welding, etc.). Cobots unshackle the worker by automating the tending process. With simple instructions, cobots can tend to several machines, resulting in boosted productivity. Also, this approach significantly reduces injury risks.

By installing an OB7 cobot, Ohio-based component manufacturer B.I.C was able to automate loading and unloading parts in its turning center cell. This resulted in scrap being cut by half, production output being pushed up by 20% and worker complaints being minimized.

- Packaging and Palletizing – Cobots can handle all processes involving packing, loading and stacking of products onto pallets, especially when there are smaller payloads involved. They can even palletize items in several patterns, and their ability to work all day reduces cycle times and labor costs.

Clearpack, a packaging automation solutions company in Singapore, deployed one of Universal Robots’ UR10 cobots. This allowed it to develop an efficient, safe and easy-to-use palletizing system. Consequently, Clearpack’s customers have since been able to witness more effective utilization of their warehouse spaces.

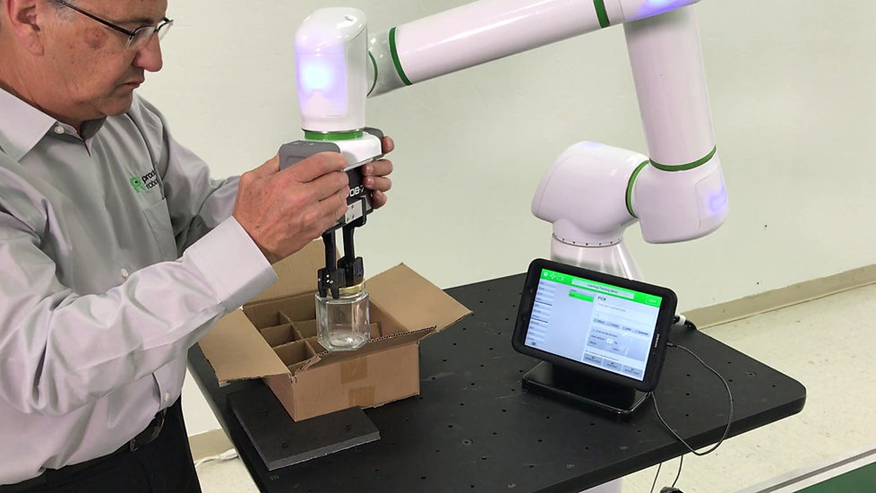

- Quality Inspection -Cobots are compatible with various forms of equipment, such as high-resolution cameras and end-effectors. By just setting up a camera on the deployed cobot, a faster and more accurate quality inspection process can be derived.

Taiwan-based robotics company Techman Robot specializes in making cobots with embedded vision capabilities. It recently deployed its technology in a leading Japanese car manufacturer’s assembly lines, for conducting final quality inspection work. The car manufacturer experienced considerable time and cost savings, while also improving quality control.

- Product Assembly -Assembly processes, such as screw/bolt tightening, riveting and electronics installation, help streamline production. Cobots are highly optimized for automated assembly in relation to medium-range payloads within tight workspaces.Opel’s Eisenach automotive plant implemented a factory-wide automation system that included UR10 cobots. These units are being used to drive screws in engine assembly. The company was able to free up its employees from a physically stressful task, that could otherwise lead to long-term health issues and lost working hours.

Cobot-Centric Factories

Cobots are going to usher in a new era of manufacturing where greater emphasis may be placed on customized solutions, and tasks/processes can be altered to solve operational issues or deal with other problems. This new breed of robot is bringing about a unique synergy where human input is able to support high-throughput automation.

The use of cobots will be pivotal in democratizing automation – enabling businesses across all industries, whether they are large or small, to participate. It is helping to shape new manufacturing trends that will be beneficial to society, leading to an upskilling of the workforce and greater job satisfaction, while maintaining the highest levels of productivity.