The importance of ergonomics and worker safety in today’s industrial and technical work environments cannot be underestimated. Engineers, electricians, and maintenance workers can significantly lower their risk of injury, increase productivity, and feel more satisfied with their jobs when they comprehend and apply ergonomic principles. The significance of ergonomics is examined in this article, which also provides simple methods for incorporating ergonomic principles into regular workdays.

Health and Safety in the Workplace

Before digging into the topic of ergonomics and worker safety it is important to bear in mind health and safety rules and regulations that are crucial in the workplace. Each country is obliged to follow health and safety regulations to ensure proper practices in their workplaces. For instance, in the EU there is an existing safety and health legislation with European Directives along with basic principles such as risk assessment and prevention.

Health and safety standards legally require employers to protect the health and safety of their workforce. It is critical for employers to take all reasonable steps to protect employees’ welfare. By doing this, you may reduce the number of absences from work, shield employees from potential hazards at work, improve productivity and happiness at work, and foster a stronger sense of company loyalty. Establishing a strong safety culture can be greatly aided by safety engineering and workplace design.

The Importance of Ergonomics in the Industrial Sector

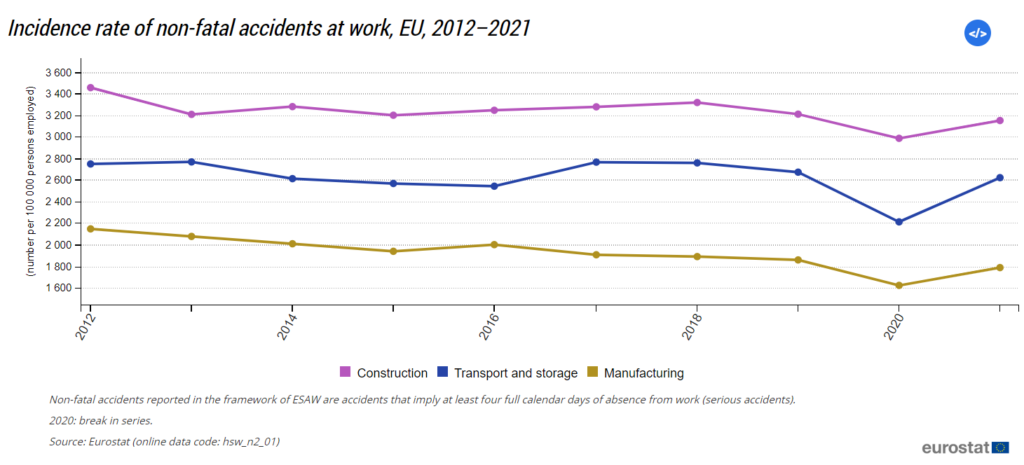

Over the course of recent years, as can be seen on the graph below, the number of non-fatal accidents at work was the highest in the Construction industry, with 369 000 (12.8%) non-fatal accidents in 2021. According to Eurostat data, in the EU, there were 2.9 million non-fatal incidents in 2021 that required workers to miss at least four calendar days of work. Between 2012 and 2019, there were almost 203 000 more non-fatal workplace accidents in the EU, or an overall rise of 6.9%.

In order to improve safety of workers, ergonomics can greatly lower the risk of accidents and increase overall efficiency in industrial environments where manual labour, repetitive jobs, and heavy machines are prevalent. The implementation of ergonomic solutions can in a large part help prevent workplace injuries such as musculoskeletal disorders (MSDs), which are frequent in industrial settings and include back pain, carpal tunnel syndrome, and tendinitis.

By minimising discomfort and fostering comfort, ergonomics boosts productivity by facilitating the timely and accurate completion of tasks. As was mentioned above, with health and safety rules in place, it is a more inviting and secure working environment which also raises morale among staff members, creating a positive environment that lowers work absence and raises job satisfaction. Ergonomic approaches also help businesses save a lot of money on workplace injuries by reducing medical expenditures, compensation claims, and productivity loss.

Key Ergonomic Principles for the Industrial Sector

1. Workstation Design

The working station design is a crucial aspect of a worker’s wellbeing and the efficiency of their job performance. Workstations should be tailored to the needs of workers, ensuring that tools and materials are within easy reach and at appropriate heights to minimise bending and stretching. Therefore, planning and creating a workspace that prioritises employee health and wellness while simultaneously increasing productivity can be achieved by bearing these design variables in mind:

- Light – to avoid accidents and minimise eye strain, adequate lighting is essential for both productivity and safety. Uniform lighting without glare is what should be implemented in industrial lighting, while task-specific lighting, such as adjustable lamps, improves visibility for in-depth work. Discover our lighting solutions from a variety of well-known brands like OSRAM, Intelligent LED Solutions and more.

- Height – repetitive strain injuries can be prevented by using adjustable workstations, which can be customised for different workloads and worker heights.

- Temperature – keeping the workplace at a comfortable temperature is essential for employees’ well-being and productivity. Regular maintenance of climate control systems is necessary to ensure that they operate in an appropriate and consistent manner, hence averting heat stress and hypothermia.

- Ventilation – in addition to eliminating pollutants and guaranteeing a steady supply of fresh air, proper ventilation also maintains air quality and guards against respiratory problems. Effective systems, whether mechanical or natural, should be customised to meet the unique requirements of the workplace.

- Noise – workers’ health may be harmed by excessive noise, which can lead to stress and hearing loss. A safer workplace requires regular noise level monitoring in addition to noise reduction techniques including soundproofing, obstacles, and earplugs. Shop our hearing protectors to ensure your employees’ hearing safety.

- Layout – A tidy workspace improves productivity and safety by clearing clutter and streamlining processes. Accidents can be avoided and operational effectiveness increased with the use of clear passageways, appropriate signage, and routinely reviewed arrangements.

2. Personal Protective Equipment (PPE)

Personal protection equipment is essential for protecting employees from a variety of workplace dangers. Workers must be thoroughly trained in the appropriate selection, application, and upkeep of PPE according to their jobs and workplace hazards.

Businesses need to conduct routine risk assessments of the workplace to identify any dangers that might call for the use of PPE, such respirators, goggles, gloves, or helmets. Furthermore, in order to avoid contamination and guarantee worker safety, it is essential to set precise procedures for putting on, taking off, and disposing of PPE.

3. Adjustable Equipment

Adjustable equipment is essential for meeting the needs of individual workers and varying jobs. The opportunity to adjust equipment improves worker comfort and lowers the risk of damage. Adjustable workstations, chairs, and equipment help employees maintain good posture and lessen physical strain on their bodies.

Each worker has a chance to personalise their workstation to meet their unique tasks, whether seated or standing, which promotes ergonomic efficiency. Additionally, by making it easier for employees to transition between various postures and jobs, adaptable tools and machinery can help lower the risk of repetitive strain injuries.

4. Proper Lifting Techniques

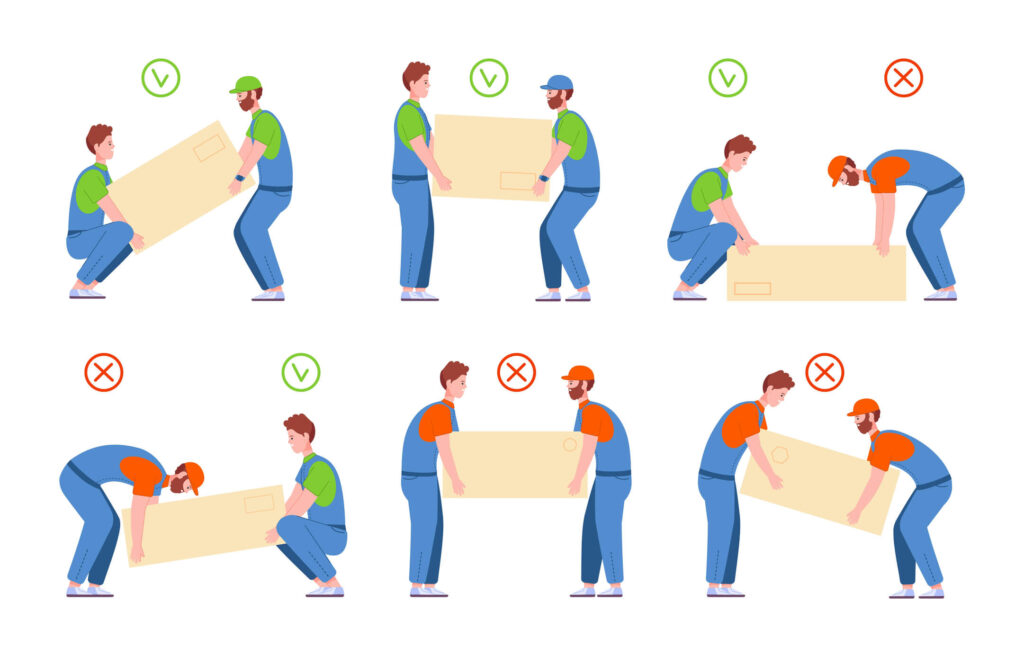

Using safe lifting procedures is crucial to prevent accidents, especially to the back and spine. It is imperative that workers undergo thorough training in lifting mechanics, load assessment, and lift planning to guarantee a clear and safe path. Important tips for lifting include utilising leg muscles rather than the back, bending at the hips and knees to maintain a neutral spine, and keeping the weight close to the body.

Reducing tension also involves avoiding twisting and moving with smooth, controlled motions. Team lifting and the use of mechanical assistance like forklifts and hoists are recommended for large or heavy goods. Ergonomic treatments like adjustable lifting equipment and regular pauses to prevent fatigue can further improve safety and lower the chance of harm.

5. Task Variation

Task diversity is a key aspect, especially in industrial sectors, like factories and warehouses, test and measurement or construction sites. The variation of tasks is also crucial to preventing repetitive strain injuries and minimising worker tiredness. It guarantees that no single muscle region is abused by alternating workers between various jobs, hence improving total physical health.

As doing a range of tasks can alleviate monotony and boredom, task diversification also aids in maintaining mental attentiveness and interest. Workers can employ diverse skills and postures when their duties are regularly changed, which can reduce stress on particular body regions and promote a more balanced workload.

Benefits of Workplace Safety

Numerous benefits of workplace safety contribute to an organisation’s overall performance and well-being. First off, it greatly lowers the likelihood of illnesses and injuries among workers, encouraging a healthier workforce and saving healthcare expenses. Businesses that provide a safe workplace also see a boost in productivity from their staff, who are more focused and efficient because they feel protected.

Additionally, upholding a solid safety record enhances the company’s brand, drawing in top personnel and strengthening bonds with stakeholders. Adherence to safety laws not only averts legal complications but also cultivates a constructive work environment based on mutual respect and confidence. In the end, putting workplace safety first not only safeguards workers but also promotes sustained development, lower expenses, and higher employee morale—all of which contribute to economic success.

The Way to Safer Workplaces

To sum up, putting industrial safety first by strictly adhering to ergonomic rules is not only required by law but also a critical strategy for creating a safe and productive work environment. Organisations can reduce the risk of workplace accidents and improve employee happiness by implementing practices that encourage good posture, effective task allocation, and the use of ergonomic tools. Adhering to these policies improves employees’ health and welfare, which fosters a culture of productivity and safety. Investing in ergonomic principles helps organisations expand and succeed over time in a global marketplace that is increasingly competitive, and what’s most important, it also protects against potential hazards.