In today’s world, where viruses threaten society, reducing the risk of coming into contact with harmful pathogens has become key. Along with improving the air quality and ventilation, ultraviolet UVC lighting gained more popularity as medical facilities started seeking more non-disposable, non-chemical disinfection options.

Ensuring a clean and safe hospital environment is crucial for the safety of patients and the medical workforce. Therefore, there are constant improvements in the healthcare industry to provide a high-quality facility performance and also reduce energy and maintenance costs. One solution is Ultraviolet-C Light-emitting diodes (UVC LEDs) that destroy dangerous pathogens in water, surface and air.

At Distrelec, it is important that the equipment we distribute is of the highest quality and safety, especially when it’s used in hazardous workplaces. Some of our supplier partners are brands like OSRAM or Intelligent LED Solutions that are drivers of innovation in the semiconductor sectors, strive towards sustainability and ‘shape the future of light’.

What are UVC LEDs?

Besides the general lighting that is important for medical personnel’s working conditions, the lighting we will be focusing on in this article is UV light. This type of light helps organisations minimise the spread of superbugs, which linger in patient rooms and lead to new infections.

LEDs are semiconductor devices that are constructed from numerous layers of substrate materials. They can be created to accept wavelength input and output photons in the UV-C range, which can be utilised to prevent bacterial replication. Ultraviolet (UV) disinfection can help fight dangerous pathogens, such as E. Coli, MRSA and C. diff.

Another term that complements the UVC is UVGI (Ultraviolet Germicidal Irradiation). UVGI is ‘the use of ultraviolet (UV) energy to kill viral, bacterial, and fungal organisms’, according to the Centres for Disease Control and Prevention. UVC LEDs are small, so they can be used in many different devices, including air purifiers, medical equipment, and water purifiers.

Benefits of using UV Light for disinfection

UV disinfection lighting improves both the patient experience and the staff’s ability to work efficiently and with special care. The key aspect of UVC LEDs is the UVC light that should be emitted at very precise wavelengths, as that is the main factor contributing to destroying the pathogens.

Features of UV light disinfection products:

- Can kill even 99.9% of bacteria and viruses

- Take two seconds to destroy the microorganisms

- Compact size

- Non-toxic

- Narrow spectrum of output centered on a specific wavelength

- Low power consumption

- Low heat generation

UV Light disinfection products safety standards

Each product with a specific application has to comply with some standards. Users or customers purchasing such equipment should know how to use the products and ensure that these devices have been tested and examined.

Distrelec offers products that come with relevant data sheets, so before making a purchase, our customers have all the necessary information about the product they wish to purchase. As UCI Beckman Laser Institute & Medical Clinic claims, it is important to remember that for UV to kill germs, it has to be shining for a certain time and at certain wavelengths

Things to keep in mind before buying UV light disinfection products:

Types

There are different types of ultraviolet C lamps with different specifications. Some make a lot of UVC light and disinfect in a short time. The most common four types are:

- Low-pressure mercury lamps – similar to fluorescent lamps with a wavelength of 253.7 nm. They produce a small amount of visible light because of additional bands of mercury radiation. Both mercury lamps with low and high pressures have negative resistance, hence an external ballast is needed to control the current flow.

- High-pressure mercury lamps – more similar to HID lamps than fluorescent lamps, are widely used in water treatment. They radiate a broad-band UVC radiation, producing bright bluish white light.

- Excimer lamps – depending on the medium, excimer lamps emit narrow-band UVC and vacuum-ultraviolet light at a range of wavelengths. They produce less heat than mercury lamps and reach peak output more quickly. Excimer emission at 207 and 222 nm seems to be less harmful compared to conventional 254 nm germicidal radiation.

- LEDs – as mentioned at the beginning of this article, solid-state UVC LEDs generate light using semiconductor components. By modifying the semiconductor material’s chemistry, it is possible to tailor the emission wavelength, which gives the LED’s emission profile selectivity over and beyond the germicidal wavelength band. According to Semiconductor Today, from 2021 to 2026, the UV lighting industry is anticipated to develop at a compound annual growth rate (CAGR) of 17.8%, with the UV LED market increasing to $2.466 billion.

Wavelength

It is vital to pay attention to the wavelength as it can impact the device’s effectiveness at destroying viruses. It can also cause health and safety risks. The product you will buy should be able to kill pathogens without causing too much health risk. The UVC devices available in the market cover a wavelength spectrum from 200 to 280 nm. According to the International Ultraviolet Association, to eliminate pathogens, specifically germicidal ultraviolet in the 240 – 280 nm range should be used.

Surface

Since it can be challenging to reach all the locations where the virus can appear, UVC solutions typically perform poorly on surfaces with ridges and bumps. They work better on hard, non-porous surfaces.

Safety features

It is important to ensure that such lamps are safe and do not cause an exposed light, for example, by choosing ‘enclosed products’ with auto switch off function.

Avoid looking at the light

UVC radiation can potentially cause injuries, so people should avoid continued contact with the skin and not stare straight at the illumination as its long-term effect on humans is still unknown.

UV Light applications

UV radiation is frequently utilised for various purposes in industrial processes as well as in medical and dental settings, including phototherapy, bacterial killing, fluorescent effects, curing inks and resins, and tanning.

Below we highlight some of the products used in different facilities that help disinfect air, water and surfaces.

UV LEDs, UV PowerStar, Intelligent LED Solutions

UV LEDs are a good solution for resin curing in dental applications. The bulb life used in traditional curing technologies, such as tungsten halogen, was substantially less than that of LEDs. Resins are now cured in a matter of seconds, a process that would have taken a long time before LED systems’ development. Moreover, reducing the amount of energy used.

Applications:

- Polymer Curing

- Ink Curing

- Counterfeit Detection

- Aquarium Lighting

- Medical and DNA Sequencing

- Inspection Equipment

- Horticultural Lighting

Find more important information and precautions about UV PowerStar here.

UV LED Boards, Oslon UV, Intelligent LED Solutions

The OSLON® UV series is intended to deliver effective UV-C radiation for a variety of consumer, household, and medical applications. It enables versatile designs for numerous UV-C applications in the fields of treatment or sensing, as well as air, water, and surface disinfection and purification.

Applications:

- Equipment illumination

- UV-C air, surface and water disinfection

- Smoke, dust, particle sensing

For more specifications, take a look at OSRAM OSLON® UV 3636 1 LEDiL Selector datasheet here.

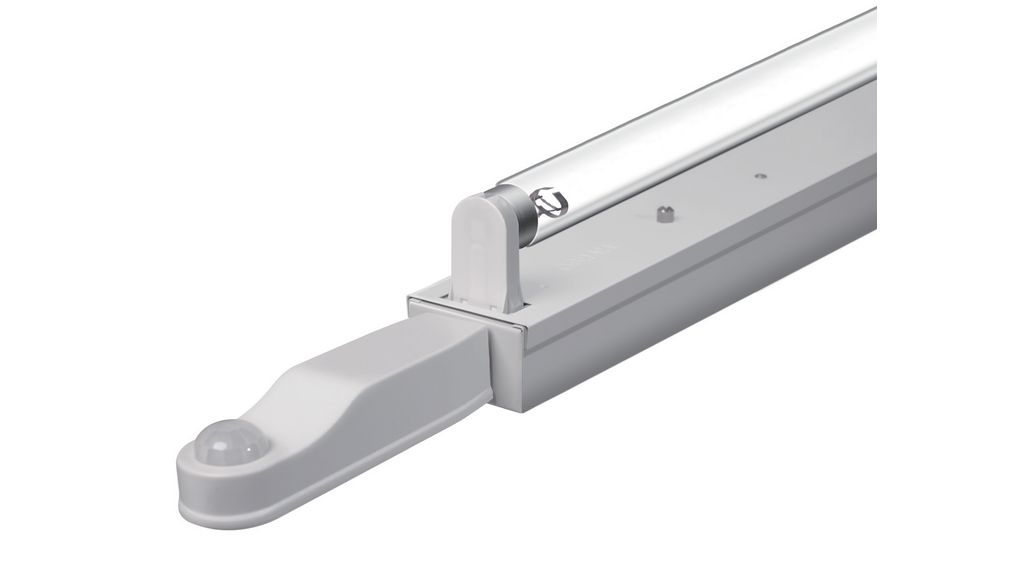

UV-C light purifier, OSRAM

An intelligent UVC lamp is perfect for use in laboratories and hospitals. With a wavelength range of 200 to 280 nm, UV-C radiation produced by high-energy UV-C lamps is very adaptable and can be used to disinfect water and kill dangerous microorganisms in other liquids, on surfaces, on food goods, and in the air. More than 99.9% of all pathogens can be eliminated by UV-C technology in a matter of seconds without the use of chemicals causing risky side effects, making it an affordable and highly dependable option. When people are seen entering the UV workspace, the IR sensor on the AirZing pro will shut down the system.

Features:

- Generates 253.7 nm UV light (ideal for highly effective sterilisation and purification)

- The proven technology in destroying up to 99.9% of the microorganisms

- It has an IR sensor to shut down the system when individuals are detected entering the UV workspace

- 30-second-delayed start to improve operational safety

- specially developed OSRAM ballasts to increase the performance of OSRAM HNS UV-C bulbs

- Ozone-free emissions

- 360-degree coverage

Applications:

- Hospitals

- Offices & Schools

- Cinemas

- Bars & clubs

- Events

- Factories & Plants

- Buses and Train Stations

- Cinemas

- Shopping centres and restaurants

- Gym and fitness centres

Find out more specifications about the UV-C lamp here.

Meeting hospital demands for a complete UV disinfection solution

Lighting is a key to efficient healthcare. Thus UVC LEDs are perfect for the equipment manufacturing and medical environments to integrate this disinfection technology into new and exciting products that protect patients from Healthcare-Associated Infections (HAIs). With the products mentioned above, you can ensure that the operation, whether in a hospital, surgical center or clinic, will be effective and safe. However, it is important to keep in mind that some of the UVC lamps can cause some harm if bought without clear specifications and user manual. Click the button below and search more from Distrelec.