Tapes and adhesive might seem like a small part of the overall building and construction process but they are essential to ensuring the structural integrity of the project.

Whether you’re a seasoned professional, industry expert or a dedicated DIY enthusiast seeking dependable solutions, 3M has the right products for you. 3M, as an American multinational conglomerate company, offers products and services in a variety of industries, from consumer goods to manufacturing, healthcare and safety. The company is a global leader in tapes and adhesives, with a strong recognition for quality and innovation.

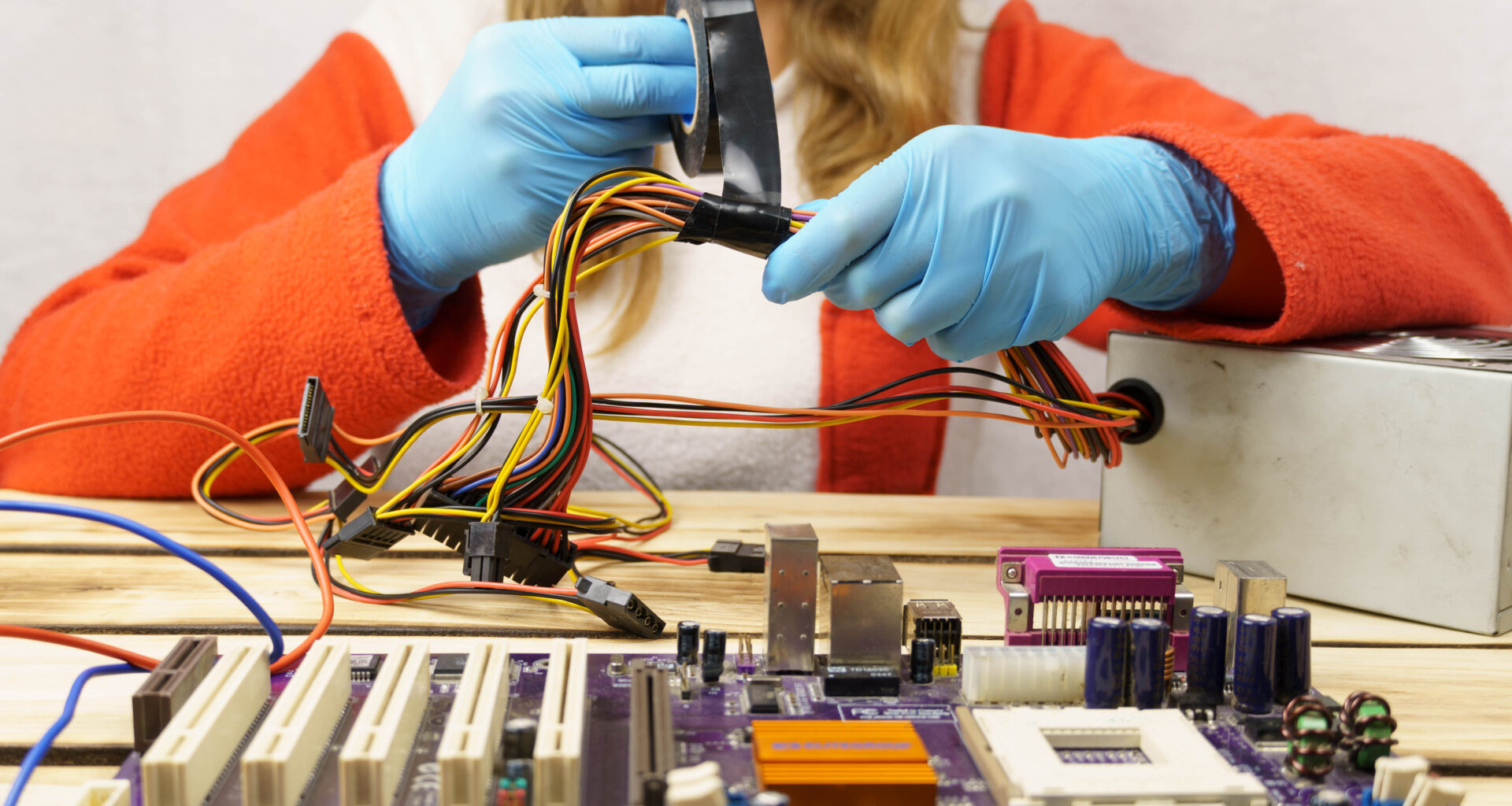

Benefits of electrical tapes

Tapes provide a number of advantages and are useful in a variety of electrical and wire applications. Because of their insulation qualities, flexibility and tolerance to different environmental conditions, they are crucial for preserving the functioning, dependability, and safety of electrical systems.

Electrical tapes are also perfect for repairing cables and wires. Have a look below to find out how to repair minor and substantial damages with 3M solutions.

Repairing cable jackets with electrical tapes

Depending on the type of cable jacket damage there are different repair solutions. 3M’s repair procedures are suitable for polyvinyl chloride (PVC) and rubber cables for low and medium voltage. These robust and budget-friendly options are ideal for tasks in tight quarters and fit both short-term and long-term cable maintenance needs.

Repairing minor damages (such as scratches and grooves):

1.Clean the surface with a solvent and abrasive cloth. 3M offers cable preparation kit CC-3 and cable cleaning wipes or degreasing and cleaning spray to prepare the surface. The 3M’s degreaser spray is an ideal dissolving cleaner for greases, oils, lubricants, resins and tar. Go straight to the Distrelec shop below to purchase.

2. Apply half a length of the cable jacket repair tape over the damaged jacket area. The 3M’s cable jacket repair tape is a professional-grade mastic tape with a strong backing made for jacket repairs on cables used on shipboards, draglines, and diesel locomotives.

3. Overwrap each end with super 33+ vinyl electrical tape which adds radial pressure and has adhesion and sealing properties.

The super 33+ tape will be suitable for the most difficult electrical maintenance and repair tasks when equipment must continue to function and failures are not an option. You can rely on this vinyl electrical tape, which is UL listed and VDE approved, whether it’s exposed to pollutants and hostile substances, extreme heat or cold, excessive humidity, or any other condition.

Features:

- Highly conformable and super stretchy

- Performs continuously in ambient temperatures up to 105°C

- Excellent resistance to UV, abrasion, moisture, alkalis and acids.

- Flame resistant

Repairing substantial damages (such as cable damage, torn jacket, intact inner layers of the cable, etc.):

- Cut off the cable jacket’s damaged edges.

- With solvent and an abrasive cloth, clean the cable surface. For this purpose, 3M recommends using their cable preparation kit CC-3, cable cleaning wipes or degreasing cleaning spray that was mentioned above.

- Fill and seal holes with 3M’s electrical insulation putty.

- Overwrap the whole repair length with cable jacket repair tape.

- Wrap super 33+ vinyl electrical tape at the ends.

Other recommended products for minor and substantial damage:

Scotch® Rubber Rubber Mastic Tape 2228, 50.8mm x 3m, Black, 3M

This rubber mastic tape is suitable for application over irregular surfaces and solid dielectric cable insulations. It has high adhesion and sealing properties so it is perfect for a flexible cost-effective solution to minor jacket repair, like copper, aluminium and power cable jacket materials.

Scotch® Super 88 Heavy Duty Vinyl Electrical Tape, 50mm x 33m, Black, 3M

This robust vinyl electrical tape combines a pressure-sensitive rubber resin adhesive with a PVC backing, ensuring both electrical and mechanical safeguarding. Designed for heavy-duty use, it exhibits impressive resistance to UV radiation, abrasion, moisture, alkalis, acids, corrosion, and various weather conditions. Additionally, it holds UL Listing, ASTM Approval, VDE Certification, CSA Certification, and complies with RoHS 2011/65/EU standards, affirming its reliability and compliance with industry standards.

To find out more about these alternative products, have a look at 3M’s Cable Jacket Leaflet here.

The Tape for Every Task

3M offers a diverse range of tapes tailored for a multitude of applications and environmental conditions. These tapes are available in an extensive array of materials and sizes, some of them we’ve highlighted earlier. For a comprehensive selection of these tapes, including common types, along with additional information, have a look at the electrical tapes guide below:

3M Electrical Tapes Guide

| General Use Tapes | Professional Grade Tapes | |||||||||

| Typical Values | 3M Temflex Tape 155 | 3M Temflex Tape 165 | 3M Temflex Tape 175 | Scotch Tape 35 | Scotch Super 33+ Tape | Scotch Tape Super 88 | ||||

| Best For | Simple Light Tasks | Light or Medium Duty Applications | Medium Duty | Medium to Heavy Duty | Medium to Heavy Duty | Heavy Duty | ||||

| Target Applications | General bundling, marking, andsecondary insulation | Temporary and/or non-critical marking,bundling, holding and secondary insulation | Semi-permanent bundling, holding and secondary insulation | Permanent low-voltage primary and secondary insulation | Permanent, low -voltage primaryand secondary insulation, cablejacketing and mechanical protection | Permanent low-voltage primary and secondary insulation, cable jacketing, mechanical protection and padding | ||||

| Application Environment | Normal temperatures and ambient conditions | Moderate temperatures and conditions | Moderate temperatures and conditions | Harsh temperatures and moist or corrosiveconditions | Extreme temperatures and moist or corrosive conditions | Extreme temperatures and moist, corrosiveor rough conditions | ||||

| Certifications | IEC 60454-3-1-1/F-PVCP/60and RoHS2015/863/EU Compliant | VDE Certified, UL 510Listed, IEC60454-3-1-5/FPVCP/90 andRoHS2015/863/EU Compliant | VDE Certified, UL 510Listed, IEC60454-3-1-6/FPVCP/90 andRoHS2015/863/EU Compliant | CSA and VDE Certified,UL 510 Listed, IEC60454-3-1-6/FPVCP/90 andRoHS2015/863/EU Compliant | CSA and VDE Certified,UL 510 Listed, IEC60454-3-1-7/FPVCP/90 andRoHS2015/863/EU Compliant | CSA and VDE Certified, UL 510 Listed,IEC 60454-3-1-7/F-PVCP/90 andRoHS2015/863/EU Compliant | ||||

| Operating Temperature¹ | 0 to 60°C | 0 to 90°C | -10 to 90°C | -10 to 105°C | -18 to 105°C | -18 to 105°C | ||||

| Thickness | 0.13mm | 0.15mm | 0.18mm | 0.18mm | 0.18mm | 0.22mm | ||||

| Sticking Power (Adhesion to Steel) | 1.7 N/10mm | 1.8 N/10mm | 2 N/10mm | 2.2 N/10mm | 3 N/10mm | 3 N/10mm | ||||

| Stretch² (Elongation) | 150% | 170% | 200% | 225% | 250% | 250% | ||||

| Strength² (Backing Strength) | 20 N/10mm | 20 N/10mm | 26.9 N/10mm | 30 N/10mm | 26.3 N/10mm | 35 N/10mm | ||||

| Insulation² (Dielectric Strength) | 38 kV/mm | 40 kV/mm | 39 kV/mm | 49 kV/mm | 45 kV/mm | 45 kV/mm | ||||

| Colour Details | Various | Various | Black | Various | Black | Black | ||||

² Based on ASTMD 1000. Not for specifications. Typical values – they should not be interpreted as minimum or maximum values. Unless otherwise specified, properties are measured at 23°C, room temperature.

³ Not all colours are accessible everywhere. Your local suppliers might potentially have different colours. For information, check the datasheet in your local market.

To find out more about different types, visit 3M’s in-depth electrical tapes guide here or browse Distrelec webshop to buy 3M’s products.

Source: 3M