Climate change is the biggest challenge we face. ‘Going green’ is not a lifestyle choice, it’s a choice for life, and even small changes – if made by a large number of people – can make a huge difference.

Sustainability presents many challenges: reduced energy consumption; higher efficiency; longer product life; increased use of renewable energy and less dependency on fossil fuels; local energy generation.

Everyone must play their part, but how does Panasonic Industry contribute to creating a greener society?

Panasonic’s Green Future

“Global environmental issues must be our top priority”…”we will confront today’s issues head-on to make sure we don’t pass society’s ills on to future generations”…

Yuki Kusumi, CEO, Panasonic.

Panasonic Corporation has made a commitment to achieving net zero CO2 emissions at all its operating companies by 2030. Looking to 2050, the company has shared its goals for contributing to society-wide reductions in CO2 emissions by switching customers to energy-saving products and supplying energy-saving solutions and green energy technologies to B2B/B2G customers.

From Energy creation to Energy consumption: Discover Panasonic Industry Europe’s wide range of technology and product solutions.

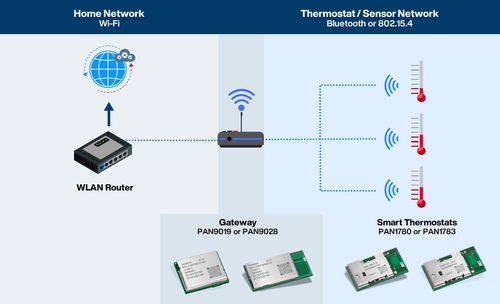

Wireless modules for smart thermostats

Panasonic‘s portfolio of wireless module solutions is the technology of choice at the core of modern smart energy applications in private, commercial or public buildings. From gateways to lighting assets or smart thermostats – Panasonic modules ensure that energy is only consumed when (and where) it is really needed.

Relays

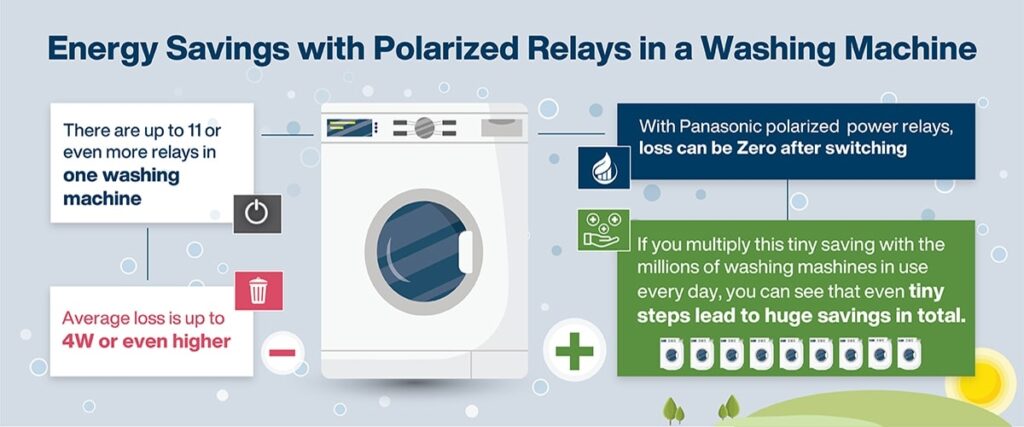

Smart meters and intelligent power distribution systems, enabled by a Cloud-based IoT infrastructure will help us consume less energy and minimise energy wastage. Panasonic Industry Europe has one of the crucial building blocks for such applications – polarised power relays, including industry’s smallest components, the 8A DSP series.

Panasonic invented the polarised relay 50 years ago. A permanent magnet is employed to increase the magnetic force of the coil, therefore less electric power is used to switch the contacts. Since its invention in the 1960s, Panasonic estimates that their energy-efficient polarised relays have saved the industry 3 billion kWh of energy in Europe. In the next ten years with the move to smart homes, smart offices, smart factories, and smart cities, we expect this to increase significantly.

Latching relays are also energy efficient as they require no power to remain in one switching state once activated.

PhotoMOS® relays also contribute to energy saving thanks to their very low power consumption. And because PhotoMOS® have no mechanical parts there is no arcing or abrasion, so the lifetime is virtually unlimited. Therefore, they contribute to sustainability and maintenance costs are minimised.

Capacitors and Power Choke Coils

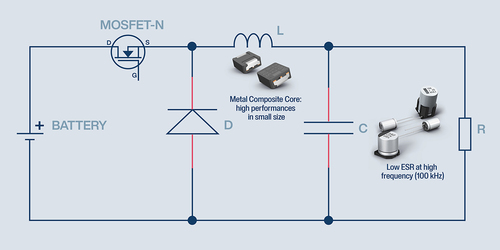

Electrical systems require power. Yet every time power is converted – either via an AC/DC power supply or a DC/DC power converter – there will be power loss. Panasonic Industry Europe offers a wide range of passive solutions including hybrid and film capacitors and power choke coils that contribute to energy-efficient power conversion by minimising power conversion losses.

Power inductors guarantee high reliability and stability during lifetime, thanks to a metal composite core made up of iron-based metal powder and a resin binding system. This high-quality design ensures excellent electrical and mechanical characteristics, even in harsh environments like low AC resistance loss, efficient thermal dissipation, miniaturisation, and stable inductance value; even at high currents and temperatures. Metal composite inductors also show very low DCR values which can help to enhance power efficiency when used in input filters and DC/DC converter applications.

In addition to power inductors, hybrid aluminium electrolytic capacitors (which are the combination of liquid electrolyte and polymer) can contribute to high efficiency levels by offering a very low and stable ESR. Thanks to the liquid electrolyte, hybrid capacitors offer a very stable leakage current behaviour as well as a highly conductive polymer material, both of which reduce noise in designs.

For applications that require even more safety, Panasonic Industry’s film capacitor fuse function technology is the most suitable. Moreover, the high humidity resistance of Panasonic film capacitors is ideal for applications used outdoors or exposed to high humidity.

EV Charging Solutions

Panasonic has been developing and supplying solutions for all kinds of electric vehicles for decades and e-mobility is a core aspect of its DNA. The brand offers all kinds of components and devices for safe, fast and reliable charging technology.

Wireless modules

For commissioning and displaying usage data by smartphone or a similar device, wireless modules serve as access points or clients. Panasonic modules offer high performance with low energy consumption and can be used in various applications, such as EV charging, making for a reliable sustainable option.

The PAN902x Series

This series of wireless modules uses a combination of Wi-Fi and bluetooth to provide the highest flexibility for connectivity, depending on which data rates or ranges are required for an EV charger application. The PAN9026 is a dual band 2.4/5 GHz 802.11 a/b/g/n Wi-Fi radio module with integrated Bluetooth BDR/EDR/LE which is specifically designed for highly integrated and cost-effective applications. The PAN9028 is intended for a more sophisticated use where higher data rates are needed such as 802.11ac. The PAN902x can connect the charging station to a network by acting as a client in order to upload data to the cloud or mobile device.

Main features:

- Dual band 2.4/5 GHz 802.11 a/b/g/n Wi-Fi/BT combo module.

- Bluetooth 4.2 (includes LE) as well as future Bluetooth 5.0 features.

- Dual simultaneous and independent WLAN and Bluetooth operation.

- IEEE 802.11n 20 MHz and 40 MHz channel bandwidth.

- Wide temperature range of -30 to +85°.

- Supports 802.11i security standards through AES, CCMP, and more security mechanisms.

The PAN178x Series

Based on Nordic Semiconductor chipsets, the PAN178x are Bluetooth Low Energy modules which are especially effective for low-power transmission of smaller data rates. In commercial DC charging stations, these modules can be integrated into a meshed network, allowing not only customers to connect without difficulty, but also giving the operator an overview of the individual charging stations in terms of occupation.

Main features:

- IP Core: Cortex M4(F) with 64 MHz.

- Temperature Range: -40 to +85°.

- Size: 15.6×8.7x2mm.

- Up to 48 General Purpose I/Os (depending on module version).

Polymer Capacitors

These advanced capacitors use conductive polymers to form the electrolyte, or the conductive polymers can be used with a liquid electrolyte in a design which is referred to as a hybrid capacitor. To fill the high endurance and temperature requirements of EV charging stations, these polymer capacitors are ideal. Due to polymerisation and boasting high conductivity, such applications benefit from a very low ESR (Equivalent Series Resistance) which is needed for power stabilisation.

Main features:

- Ultra-low ESR for power stabilisation.

- Long endurance at high temperature, 20,000 hours at 105°.

- High reliability for outdoor usage.

- AEC-Q200 compliant.

- High temperature resistance up to 150°C.

- Perfect for AC/DC and DC/DC converters.

Film Capacitors

The integrated safety function is the standout feature of Panasonic’s film capacitors. An original in-house patterned metallisation process is the basis of a special structure serving as a fuse mechanism function that prevents short mode failure. It also achieves a very stable capacitance level over the capacitor’s lifetime, making it highly reliable. In addition to this, a long lifetime is achieved through high temperature and moisture resistance using originally developed sealing technology.

Main features:

- Rated voltage 275VAC to 310VAC (EMI suppression), 600VDC to 1100VDC (DC smoothing).

- -40°C to 110°C.

- AEC-Q200 compliant.

- Built-in fuse function.

- High moisture resistance.

- Flame retardant plastic (case and sealing resin).

Chip Resistors

All of Panasonic’s chip resistors use soft termination technology. This means by using a soft resin, the solder joint experiences less stress in temperature cycles, ensuring minimum risk of solder joint cracks.

Recommended series for EV charging:

- High temperature thick film chip resistors (ERJH series).

- Anti-surge thick film chip resistors (ERJP series).

- High power wide terminal thick film chip resistors (ERJB and ERJD series).

Main features:

- Soft termination technology for highest solder-joint reliability.

- Resistance values from 1Ω to 10Ω.

- High precision by tolerance as low as 0.05% and TCR as low as 10 ppm/K.

- High temperature up to 175°C.

- AEC-Q200, RoHS, and REACH compliant.

- Anti-pulse and anti-sulphur types available.

Relays As a Main Switching Element

AC switching elements are a crucial part of safety and protection function in charging stations and cables. Key parts of the HE line-up are the 35A HE-S with two contacts and 40A HE-R relay with four contacts. Both relays have gone through enhanced short-circuit testing to deliver a reliable and safe solution.

The HE-R relay undergoes strict testing procedures, including the IEC62955, a 10kA short circuit test. As a result, customers are now able to request their 22kW wallbox to accommodate up to 32A at 10kA short circuit current, providing optimal protection for EV charging equipment.

The smaller HE-S relay now complies with the IEC62955 standard for 3kA short circuits, providing customers with the flexibility to use the HE-S series for wallboxes rated up to 16A. This feature enables the selection of charging equipment for a wide range of applications.

| Series | HE-S | HE-R |

| Switching current | 35A AC | 40A AC |

| Contact configuration | 2a, 2a1b | 4a, 4a1b |

| Dimensions | 30x36x40mm | 35x58x47mm |

| Holding power | 170mW | 490mW |

| Contact gap | 3.2mm | 3.6mm |

Relays for Control Side

Beside the power line, charging stations include a lot of systems for communication, system control, safety functions and HMI. Wherever switching must be electrically separated from the control circuit, electromechanical or optocoupled semiconductor PhotoMOS® relays are used. The AQY series, for example, is used in charging station battery storage systems to isolate internal from external signals.

PhotoMOS® relays realise galvanic isolation by an LED that emits light through an isolator to a solar cell. The solar cell drives the MOSFET output.

Connectors

To increase the charging speed and relieve the power grid, future charging stations will reuse EV car battery packs. CF1/CF2 series of Board to FPC connectors give a smart and robust connection battery management system with only two parts, a plug and a receptacle. This saves time, money and space. For connecting displays with keyboard or touch function with the control board, Y5B Series as FPC and FFC connector can be used.

Main features:

- For automotive applications, 125°C heat resistance.

- Contact reliability is preserved by double-sided contact structure.

- Weight and process cost reduction.

- ‘Anti misoperation bridge structure’ prevents unintended operation of mating lock.

- Inertia lock construction prevents half-mating.

Graphite Thermal Interface Material

GraphiteTIM, a Panasonic exclusive material using highly crystallised graphite, transfers heat generated from a power device to a heat sink with excellent thermal conductivity. In addition, the high compressibility effectively fills the voids between the heating and the cooling device to achieve even lower low thermal resistance. Compared to grease,

GraphiteTIM has a stable heat dissipation for a long period of time due to no deterioration and pump out effect.

Main features:

- Low thermal resistance

- High compressibility

- High reliability

- Operating temperature -55 to +400°C

- Easy handling and easy to install

Check out a variety of energy-efficient solutions from Panasonic on the Distrelec web shop.