Industrial architecture must be capable of managing the data flow in a seamless and secure manner.

In the digital world everything is interconnected and saved on the cloud, the same applies to industrial automation. In the fourth industrial revolution, both machine and system operators benefit from better network, interlinked communication and exchange of data. This is where seamless connectivity enhances such operations.

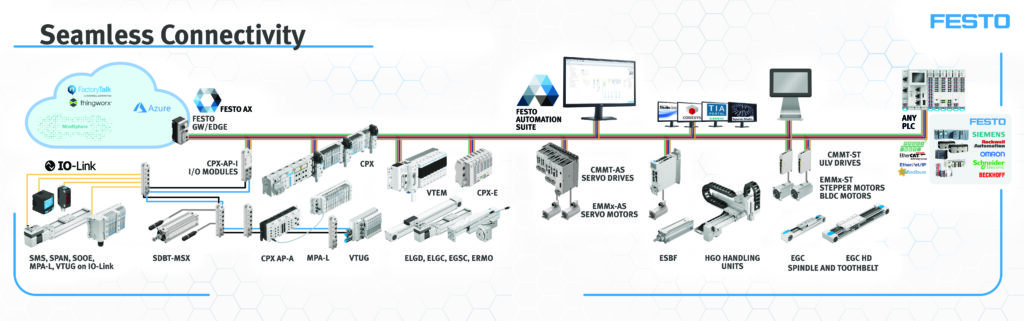

To find out more about how you can empower your business, read the following article and discover Festo’s solutions for your complete automation architecture, taking into account everything from the mechanical system to the motors, servo drives, actuators and motion controllers all the way up to cutting-edge industrial cloud solutions.

What is seamless connectivity?

Seamless connectivity is the connection of all interfaces in industrial automation and their smooth interaction. Through the integration of seamless and digitally networked automation technology, engineering processes and automation concepts are streamlined, accelerating the entire engineering journey. This integration focuses on ensuring precise coordination among mechanical, electrical, and intelligent automation platform interfaces, enabling a harmonious and efficient operational framework.

Thanks to digital and automation technologies it is possible to improve production and monitor data in real time. Digital twin and open communication standards enable the deployment of decentralised intelligence in components and controlling production. But those are not the only advantages. Have a look below at the enhancing power of seamless connectivity.

Benefits of seamless connectivity:

- Uniform software platform

- Flexible and modular concepts

- Flexible adaptation to the requirements and provides possibilities for standardisation

- Direct connection of a servo drive to a variety of different controllers

- Seamless and reliable data across the entire development and production process

Festo’s Seamless Connectivity

Festo, as one of the brands which strives for more digitised and advanced technological solutions, has developed a complete automation architecture to connect hardware, such as motors and servo drives, and software, such as dashboards and cloud solutions seamlessly. Specifically the use of the IoT Gateway CPX-IoT as a medium to connect the Servo Drives CMMT-AS with Servo Motor EMMT-AS (check the product datasheet here). The brand ensures that all the products work seamlessly together but also work with the world’s most popular networks and machine architectures.

Festo bears in mind customers who want to easily and quickly use the mechanical and electrical interfaces, when designing automation architecture. Whatever your preferred network protocol and controller platform is, Festo components will work with it.

Festo drives and controllers support multiple network protocols and PLCs. A machine running with Festo drives can easily be configured for Siemens customers as the FESTO drives are compatible with other brands’ products, just the PLC has to be changed. Via IO-Link and Festo AP you can also integrate pneumatic sensor data into the design, making pneumatics ready for industry 4.0.

Seamless connectivity in automation technology

The role of connectivity in automation technology, understood as the ability to connect and link up individual participants, or the interfaces (intelligent, mechanical and electrical), has to interact perfectly at all times, from the design process to engineering and commissioning.

- Intelligent connectivity – Festo’s decentralised control of individual process modules, along with flexible communication among control devices and integrated motion control solutions, empowers a wide spectrum of industrial automation solutions. These capabilities are enhanced by innovative engineering and configuration software, creating a robust framework for your automation needs.

- Electrical connectivity – the array of servo motors and drives by Festo serves as the perfect bridge between your mechanical setup and control technology. This seamless connection is expertly synchronised and effortlessly configured using their dedicated engineering software.

- Mechanical connectivity – Festo’s broad assortment of mechanical linear axes and rotary modules provides nearly limitless options for automating motion. These solutions seamlessly align with your in-house standards and, naturally, are fully compatible with the brand’s range of servo motors.

Festo Automation Experience

Additionally, seamless connectivity does not only apply to the servo drives. The Festo Automation Experience (Festo AX) is a simple solution that enables you to get the most out of the data generated by your system through machine learning and artificial intelligence (AI).

By employing Festo AX for data analysis, you can elevate productivity, reduce energy expenses, avert quality setbacks, enhance your shop floor operations, and even innovate novel business models. Additionally, Festo implements a tailored solution for its customers, integrating predictive maintenance, predictive energy optimization, and predictive quality enhancement.

Why choose Festo?

With the growth of advanced technologies and incorporation of IoT, AI and machine learning in Industry 4.0 and automated processes everything is seamlessly connected. The seamless connectivity solutions offered by Festo pave the way for a future where efficiency, flexibility, and innovation reign supreme. It helps customers save energy, reduce cost, and increase efficiency while giving a seamless journey. From the precision of decentralised control to the adaptability of motion control solutions, Festo’s comprehensive portfolio empowers industries to not only meet the demands of today but also anticipate the challenges of tomorrow.