Adapting to industrial changes can still be a challenge for some companies. However, the progress has not stopped since the beginning of the first industrial revolution around the 1800s. Through centuries of investing in new devices and more technological equipment, finally, companies can welcome industry 5.0. What does it mean for industry 4.0? And what will be the fifth industrial revolution? In this article, you will find answers to these and more questions.

Industrial revolution progression

Human civilization was going through some drastic changes due to industrial revolutions. One was converting agriculture and handicrafts-based economies into sectors based on automated manufacturing and the factory system.

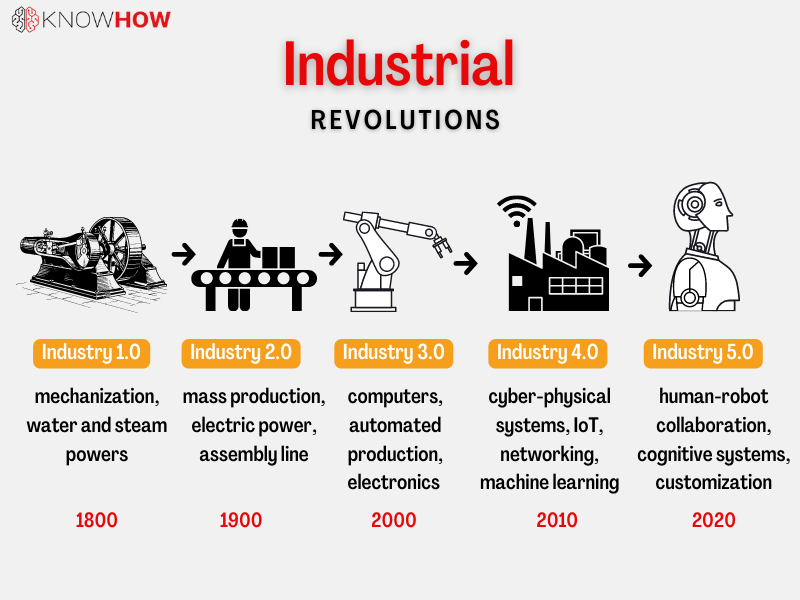

Revolution 1.0 began with mechanisation and steam and water power. Later, the second revolution implemented electricity, mass production and assembly lines, third industrial computers, automation, and electronics. The first three revolutions transformed the way society is working and living. Now companies are more productive and efficient due to new machinery, new power sources, and new ways of arranging work.

We are now in the midst of the cyber revolution, often known as Industry 4.0 or cyber-physical human intelligence. The fourth revolution is about machines replacing humans and transforming manufacturing into IoT-integrated smart facilities. It means that the industry 4.0 focus is on Artificial Intelligence (AI), computer-based systems (cyber-physical), networking and cloud servers, machine learning, 3D printing, autonomation, VR, and computing’s advantages. Check how Eaton is pushing the boundaries in Industry 4.0.

What is Industry 5.0?

Industry 4.0 is not fully incorporated yet, so why do people already talk about industry 5.0? Whereas Industry 4.0 was about connecting automation and digitalisation, industry 5.0 collaborates between humans and machines.

The fifth revolution is about connecting people with robots and making them work together. The fourth revolution started around 2010 and changed the way companies functioned. Thanks to advanced technologies and automation, many companies were able to replace humans with robots. Many businesses have been influenced by Industry 4.0 so far. Some still adapt to the technologies that industry 4.0 has brought. Does it mean that Industry 4.0 will be over? The fourth revolution doesn’t end yet and will continue to impact many companies.

Nevertheless, now the focus is on Industry 5.0 as one of the top trends in industrial manufacturing in 2022. Simply put, Industry 5.0 is the reintroduction of humans and minds into the industrial structure. Here humans and machines reconcile and collaborate to benefit from new production efficiencies. Companies that are only starting to adapt to Industry 4.0 may find themselves in the middle of this new industrial revolution.

What does Industry 5.0 mean for manufacturing?

The robotic manufacturing co-worker in industry 5.0 is supposed to successfully act as a human companion, resulting in improved production processes and waste and cost reduction. The interaction between humans and computerised machinery will drastically improve the optimisation and automation of many enterprises. Collaboration between the two industrial processes entities will offer new techniques and ideas for managing a workforce that includes both people and software robots.

Besides robots, the next industrial revolution level will bring cobots or differently called collaborative robots. Cobots can observe, learn, and execute jobs the same way as humans. Thanks to their partnership with humans there is potential of increased production efficiency and improved operations. By merging workflows with intelligent systems, this mix of people and machines will also assist organisations in focusing on enhancing brain potential and creativity.

Manufacturers will benefit from taking away repetitive tasks. Businesses will seek artificial intelligence machines to increase productivity and empower workers, once robots become more accessible. Hence industry 5.0 will create more jobs than eliminate as new skills will be required in programming, controlling intelligent systems, and emerging technologies.

Important factors about Industry 5.0

Because Industry 5.0 just entered the market, there are some speculations in regards to the impact of the new industrial revolution on life and work. Take a look at some sentences below to dispel your doubts:

- Robots aren’t supposed to supersede humans but co-op with them.

Some people worry about the impact of robotics development on human life. While robots are more reliable than people and are better at precision work, they lack adaptability and critical thinking skills. The main purpose of robots is to fulfil their assigned mission of offering aid and improving our lives when they collaborate with people.

- Industry 5.0 will bring broader benefits to the marketplace than industry 4.0.

Industry 5.0 could not exist without industry 4.0 that brought automation. However, it will change automation to manufacturing tasks while allowing consumers to acquire goods and services that are tailored to their requirements.

- Industry 5.0 will create more jobs than eliminate.

We were already thinking about robots taking human jobs in previous articles. But the conclusion is that automation opens more job opportunities than it displaces.

This new data reveals that 96 jobs across seven professional clusters are fast emerging in tandem reflecting “digital” and “human” factors driving growth in the professions of tomorrow.

World Economic Forum

- Personalisation will lead, not mass production.

Thanks to Industry 5.0, people will be able to personalise their products better as the original designs need human interventions.

- Psychology will control technology.

Ensuring product quality requires human interventions. In industry 4.0, many products created for a big scale didn’t need human touch. But the new revolution will allow workers to interfere with the product with robotics help and psychological analytics.

- The progress into industry 5.0 is inevitable.

With the growth of technology, there is no way to go back. Everything is computerised nowadays. So instead of thinking about the sense of robotics, it is better to focus on implementing changes and preparing workplaces and the workforce for industry 5.0.

Are you ready for the new industrial revolution?

Without constant development, humans could not exist. Therefore, the world and industrial sectors are going through some revolutions. But how will the development of robots and cobots result in human life? Can we expect some danger from these machines like it shows in some science fiction movies?

The question about the need for robot development is controversial because, on the one hand, it picturises a list of improvements, if only in manufacturing but also in transport, healthcare, agriculture, earth and space exploration. On the other hand, it creates a fear of the unknown. People simply do not know what the future will bring; we can only predict. But there is a danger with every invention. That doesn’t mean we should stop discovering and improving.

The truth is that people already have contact with robots by chatting with them (chatbots), getting some information from virtual assistants (Alexa/ Siri), while driving (parking sensors) and much more. With an increasing number of jobs, individualised products, automated machinery, and delighted customers, Industry 5.0 is the way to go for many companies. However, before that, governments all across the world, as well as the world’s major high-tech corporations, must establish a framework for defining machine intelligence rules.

Frequently Asked Questions

Smart factory or smart facility is often called digital factory, intelligent factory or smart manufacturing. These names describe modern technology used in facilities to generate a hyperflexible, self-adapting production in which automation, additive manufacturing, IoT, robotics, data analysts and cloud systems are used.

Industry 5.0 is a new manufacturing concept that emphasises the interaction of humans and machines. Industry 5.0 is the next phase after industry 4.0 and it entails cooperation between increasingly powerful and precise machinery and the human being’s unique creative potential.

The mix of humans and machines in the workplace is what the Fifth Industrial Revolution (5IR) will be. Industry 5.0 is distinct from the previous four because in the fourth revolution, automation was replacing humans, now people are at the centre of the manufacturing process.

Since about 2010 humans have been in the 4th industrial revolution. It means advances, such as machine learning (ML), artificial intelligence (AI), the Internet of Things (IoT) and Industrial Internet of Things (IIoT), 3D printing, virtual and augmented reality, autonomous vehicles, quantum computing and more.

Beginning with Industry 1.0 that started in the 18th century developing steam and water engines till Industry 2.0 that began the era of electricity, mass production and assembly lines, and industry 3.0 with industrial computers, automation, and electronics. The significant growth of technologies started developing in industry 4.0 by implementing automation and data exchange in manufacturing technologies.

Many people wonder what will be the main benefits of artificial intelligence. The advantages for businesses and workers are numerous, ranging from improved talent acquisition and retention to energy savings, agility, and increased productivity, profitability or enhanced flexibility, change-readiness, and a responsive working environment.

The industrial sector overall improved human’s life by developing technologies and make better ways of working. However, industrialisation is related to environmental pollution. This is why it is important to create smart manufacturing with focus on sustainability and reducing greenhouse gas emissions.

The development of smarter and more connected machines opens up a world of possibilities. Manufacturing can change Industry 5.0 by combining cognitive computing capabilities with human intellect and resourcefulness in collaborative operations.