Soon, the communication between humans and machines will change, beginning a new industrial revolution. The development of Industry 4.0 might give way to Industry 5.0. However, before companies fully embrace the transformation, organisations have to focus on changing their enterprises into smart factories with automated production, IoT, smart data, AI and new technologies.

Along with the industrial progression, visualisation systems need to provide more efficient ways of interaction on a machine-operator level. These next-generation user-machine interfaces offer a unique opportunity for each factory plant to differentiate on the market in implementing the right solution and advancing to the true digitalisation world of the HMIs operation of an automation system.

What is HMI?

Human-Machine Interfaces (HMI) are often used in industrial manufacturing and systems. They are necessary for controlling and signalling automation devices. Human-machine interface products help operators control machinery and optimise efficiency by providing information about progress and mechanical performance. Basic HMIs with LED indicators and more complex ones with touchscreens and additional features are available on the market.

Touchscreen human-machine interfaces (HMIs) for industrial automation are an established technology that give value to many machine and process automation applications by expanding the capabilities of switches, buttons, and lights in a control panel. The touchscreens are based on components, such as touch controllers and software drivers. Touchscreens common control features allow the system to react when a particular surface is touched. The touch sensor is the touch-sensitive surface. Touchscreens can be operated by fingers and keyboards or mouses.

When reviewing HMIs, it is important to know:

- Integrated requirements and various connection options for controllers.

- Configuration of HMI applications.

- Implementation of individual hardware and software requirements.

- Industry-specific certifications and approvals.

- Operator panels in various sizes and performance classes

- Use of various materials and touch technologies.

- Implementation of customer-specific design adaptations.

Selection guide for HMI devices

Depending on many factors, including display resolution, number of drivers used in parallel, memory required for the visualisation project, number of connected controllers, number of logs, HMIs might differ. The guidelines for HMI devices are described in Phoenix Contact Selection Guide, and some of them are detailed below:

Display size & resolution

Often, the resolution of the display can be problematic. Operators wonder if the panel should have a small or big screen size and what is the best resolution required to show the graphic object details correctly. The operator should thoroughly assess each use case for an HMI to ensure that the right solutions are chosen based on the application requirements.

More extensive displays provide programmers with better space to work with when creating graphics. Most users would want as big a display size as possible, particularly if they need to choose touch links, but also if the application is view-only and they wish to monitor the display from a distance.

Recommended display resolution for these panels are:

- Basic applications: with VGA (640 x 480 pixels)

- Standard applications: with SVGA (800 x 600 pixels)

- High-end applications: with SXGA (1280 x 1024 pixels)

System communication

The system connectivity requires most often an Ethernet port that the HMI can communicate on the PLC network. The Phoenix Contact HMIs have a 250 ms to 1000 ms polling rate speed. The number of drivers that are possible to use in parallel is one Ethernet for basic applications, 1 plus OPC communication in standard applications and 2 plus OPC communication in high-end applications. The number of PLCs per driver is 1 to 5 and 1 to 10 for connected at the same time PLCs.

Memory requirement

It is critical to ensure that the CPU and memory capacities of a system are sufficient to control it. Expandable memory or different memory sizes in HMIs may eliminate some limitations. Advanced features like on-board computations, trends, and recipes will have an impact on HMI performance, thus it’s recommended to utilise cautious estimates.

According to Phoenix Contact guidelines, the memory required for visualisation for basic applications usually differs between 16 and 32 objects per page, with space for animated objects (usually one per page). In standard applications, the number of pages increases to 64 with the opportunity for 128 objects per page, with a maximum of 32 scalable objects and 5 animated objects per page. However, high-end applications allow for 256 pages, 512 objects, 64 scalable objects, and 5 animated objects.

Data applications become easier now with HMIs support, where users can install their removable storage for data logging on HMIs with one or more SD Card slots.

Users & Logs

In the topic of user management, depending on the application (basic, standard, high-end), the number of users varies between 16 to 512 and up to 1024, also allowing for user groups (up to 64). On the other hand, logging allows for 4 to 16 number pens with a maximum number of data loggers per project in standard and high-end applications between 16 to 32.

What to consider when choosing HMI for your project?

HMIs can be simply put in two main categories. There are basic HMIs and wireless networked HMIs. To choose the correct one, whether it is a central control room, in production or visualisation directly on the machine, we present different brands to make choosing an HMI solution easier.

Phoenix Contact

According to Phoenix Contact, achieving cost-reduced automation requires efficient monitoring and input. Depending on the category of application (direct, high performance, multifunction) determines the Phoenix Contact HMIs features. Check the Phoenix Contact operator panels range to fit your hardware and software needs.

The advantage Phoenix Contact offer:

- Custom-made solutions.

- Easy to use with pre-configured and pre-installed hardware and software.

- Simple scalability.

- Part of the complete line system with HMIs.

- The same software version for all versions and capabilities.

- Long-lasting and strong with the aluminium front.

- Flexible controller connection.

- Web connection and efficient multi-user operation.

Touch Panel 9″ 800 x 480 IP65 Ethernet/USB/SD Card, Phoenix Contact

The touch panel from Phoenix Contact has 22.9 cm/9 inches TFT-display that is projective-capacitive and based on four-touch control. The resolution is 800 x 480 pixel(s) with 16.7 million colours, Arm® Cortex® A8, 1000 MHz, 2x USB host 2.0, 1 x Ethernet (10/100 Mbps), J45, Windows® Embedded Compact 7 and user software: It’s an open platform (there is no transit system).

Siemens

Siemens specialises in operation and monitoring devices in the 2nd Generation. Their visualisation devices increase the process quality with compact plants or smaller applications. The SIMATIC HMI Basic Panels 2nd Generation offers new operational and monitoring opportunities, especially for mechanical engineers.

The Basic Panels 2nd Generation, except for the quality and display size, offer plenty of innovative functions, such as recipe management, alarm logging, trend function and language switching. The innovative user interface opens up a wide range of functions with better usability through new controls and graphics.

The main features of the HMI Basic Panels 2nd Generation:

- Ideal for simple HMI applications.

- Designed in the TIA Portal.

- SIMATIC HMI Comfort Panels mounting compatibility.

- Flexible scalability within the HMI range.

- High-resolution and widescreen displays.

- Improved usability and an innovative user interface.

- Enhanced graphics and controls.

- Intuitive operation with touch/key functionality.

- Connection interface for many PLCs.

- Versions for PROFIBUS or PROFINET.

- Possible to store data on a USB stick.

- Mount compatible with SIMATIC HMI Comfort Panels and SIMATIC HMI Basic Panels 4″ and 6″.

Businesses who embrace the next Generation of User Experience (UX) early will come out on top in the future, winning big opportunities due to their advanced efficacy. Check some of the Siemens new visualisation systems.

HMI Panel Ktp700 Basic 7″ 800 x 480 IP65, Siemens

The HMI Panels are designed for operating and monitoring machines and system components. They interact with the SIMATIC S7-1200. SIMATIC STEP 7 Basic software is used for configuration, so no additional software is required. Basic HMI functionality: system for signalling, recipe management, graph functionality, ability to customise buttons and language transition. It is possible to connect to a PROFINET/Ethernet network. Other features: appealing industrial design.

Eaton

The Eaton HMI operator interfaces are true analogue touchscreens with customisable function buttons for even the most demanding applications. Eaton’s visualisation and automation solutions are ideal for optimising the manufacturing process. Thanks to predictive maintenance and monitoring of machines and devices, the factories improve their plants. Read more about how Eaton is pushing the boundaries in Industry 4.0.

Eaton separates HMI components into hardware and software. Hardware HMIs are often known as the OI. Hardware is an online unit or operator station which provides information about the machine’s functionality. It usually has a display, touchscreen, keypad and communication ports. Whereas software HMIs are PC-based, configured and transfer applications to and from the OI. They include runtime and development.

Eaton HMI operator interfaces features:

- An extensive driver list and three serial connection ports.

- Range of screen sizes and colours.

- Possible to connect to a parallel printer, Ethernet network or even I/O modules.

- No need for a separate controller.

- A user-friendly program editor (HMisoft software) makes configuring application parameters easier and adds new features to simplify monitoring systems.

- Entire application stores (HMI stores everything, including images, so editing does not require original source files).

The types of Eaton’s HMI display panels increase operator confidence and cooperation, reduce downtime and material losses and enhance product quality. Their offer includes dual-scan LCD colour screens, active matrix TFT colour screens—the screen size ranges from 3.5 to 22 inches of display panels. Check the Eaton’s HMIs.

HMI Touch Panel 12″ 800 x 600 IP65, Eaton

The HMI Touch Panel has interfared single touch display with 12 inches and operates panel for front installation. Features: 24 VDC, IR, 800 x 600 pixels, 2x Ethernet, 1x RS232, 1x RS485, 1x CAN, 1x DP. The user can customise the PLC function.

Omron

Omron HMIs offer a wide range of different types of human-machine interfaces. Omron NA Series HMI, Omron Compact HMI, NQ5 HMI, PC Based HMI, HMI & Control, Scalable HMI, NT25 HMI and Function Key HMIs. All of them have slightly different features and are for various applications. However, the main advantage of these next-generation machine interfaces is that these devices improve control and monitoring and enable a better connection between operator and machine.

Omron NA Series HMI main features:

- Clear and bright display with 1280 x 800 high resolution.

- Available different widescreens in all models in 7, 9, 12, and 15 inches.

- Two Ethernet ports are available for simultaneous access from the control and maintenance segments.

- NJ variables are shared in the NA project to decrease development time, and NA applications are tested with the NJ programme via the Simulator.

- Sysmac Studio provides an Integrated Development Environment.

- Many security features include operation authority settings and execution restrictions with IDs.

- Multimedia, such as video and PDF.

Omron Industrial Automation is one of the leading manufacturers of advanced technology in automation. See the whole range of Omron HMIs and accessories.

HMI Programmable Terminal 15″ 1024 x 768 IP65, Omron Industrial Automation

The NS-series transform HMIs machine from simple operating panels into plant management tools. The HMI programmable Terminal has 15 inches display size with colour TFT and XGA 1024 X 786 pixels. The screen memory size of 60MB, controller link, USB Slave, Ethernet, memory card, RS-422A/485, USB Master, RS-232C x 2, video with RGB input only.

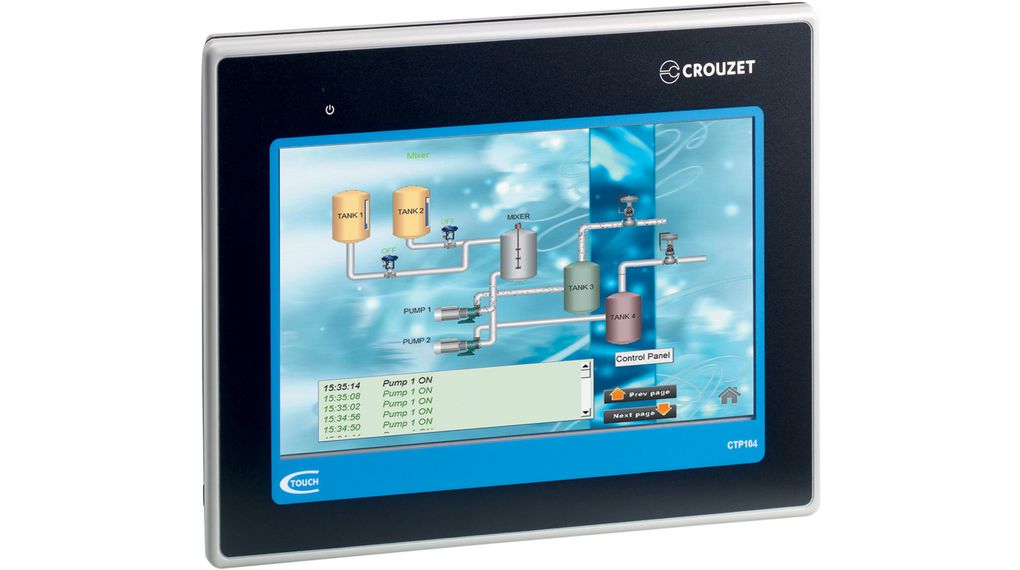

Crouzet

Crouzet Touch HMI are intuitive user interfaces for complex applications, including data analysis, recipe database, alarm handling, macro computing, tag management, and pass-through functions. The Crouzet touch software allows for online and offline simulation.

Crouzet Touch Panels main features:

- Offer a wide range of tools.

- Dedicated communication drivers for em4 and Millenium 3 enable easy label management and addressing.

- Crouzet Touch Utility Manager allows you to manage all of your HMI projects.

- Existing MTP HMI programmes can be imported into the new Crouzet Touch Soft.

- Project organisation with name displays.

- Enable to create your own library and for pictures import.

- Available in 8 different languages.

- Easy to create any functional object in the main window.

- Associated communication type.

If you are looking to visualise and conceive your projects in an easy way, check Crouzet Touch Panels that offer improved performance HMI devices.

Touch Panel 7″ 800 x 480 IP65, 800 x 480 Pixel, Crouzet

The 7 inches HMI Touch Panel from Crouzet provides a real-time clock built-in Cooling system with no fans Millenium 3 programming port direct communication with VNC built-in server. The resolution is 800 x 480. The interface type: Ethernet RJ-45, RS232, RS485, USB 2.0.

Red Lion

Red Lion offers sleek, rugged, flexible HMI panels. Depending on the application, for factories or extremely remote locations, these HMIs enable customers to connect, monitor and control the whole processes in many types of industries, including factory automation, oil & gas, power & utilities, water/ wastewater, maritime, plastic extrusion, data acquisition and IIoT.

Features of Red Lion’s HMI Panels:

- Serial ports (depending on the HMI type from up to 2 or 4)

- USB Host available in some of the HMI

- Ethernet (1 or 2)

- C-Type User Programming

- Protocol Converter

- Expansion Ports

- Temperature range (from -10° to maximum 60°C)

What is so unique about these Red Lion HMIs is that they have touch screens and incorporate modular I/O, a space-saving opportunity having 2 in 1 components.

Indoor HMI Operator Panel, 24V 10″ 640 x 480 IP66, Red Lion

This Graphite® HMI from Red Lion is the first industry’s rugged HMI touchscreen that combines I/O modules with protocol conversion, web-based monitoring and data logging. They are available in different sizes from 7 to 15 inches, perfect for indoor use with drivers to convert over 300 industrial protocols.

Wago

Wago is one of the leaders in automation products and electrical interconnection. Their HMI panels are powerful and offer an outstanding design and advanced technology. These devices enable simple data processing and monitoring for machines, systems and control technology applications.

Wago Touch Panels and Displays benefits:

- Fast operating speed with high-performance processors

- Better reliability with tackling automation systems

- Connection to WAGO’s cloud solutions

- High-performance HMI displays

- Support new technologies

- Programmable in different languages

- PLC functional

- Enable offline simulation

- No fan

Discover the range of Wago Touch Panels in different sizes and with other features.

Touch Panel 15″ 1024 x 768 IP65, Wago

The Wago I/O Pro development environment is for applications and visualisations created and completely programmed. Existing CODESYS projects can be converted and improved almost entirely. Features: TFT display, 16 million different colours, 500:1 contrast ratio. Communication: MODBUS (TCP, UDP), Ethernet, Modbus RTU, CANopen.

If these HMIs do not fulfil your applications, Distrelec is a distributor of touch panels from other brands. Check out Beijer HMIs and accessories and Schneider Electric Human-machine interfaces.