Manufacturing is still growing and developing very fast. But to properly adapt to the changes, many factories and companies will need to face a lot of challenges in 2022. The new year is a good time for setting new goals and trying to overcome disruptions. In past years most common were labour shortages so the key now is to attract new potential employees. Besides that, companies were fighting supply chain problems and workers adaptation in automation.

In the past two years, the Covid pandemic had the biggest impact on the way many businesses were working. Both 2020 and 2021 were difficult years for industrial sectors. But what about the year 2022? Is your company ready to face the new challenges? This article will go through the current trends that will shape manufacturing in 2022.

Smart Manufacturing

In today’s world, the most important thing is the right adaptation to technology. Past decades proved that technology is the right direction to improve and develop people’s lives. Especially in times where many machines met downgrades or production had to be controlled remotely. As the reality keeps changing and surprises everyone, the companies owners and manufacturers have to focus on new technologies.

By 2025, the top 50 consumer goods manufacturers will have invested in a brand app using AI, embedded technology in the product, videos as a digital asset and/or integrated innovation with IT and R&D teams.

Gartner

Thanks to smart manufacturing (SM), manufacturers can analyse trends in the data to see if there are any points in their processes where production is slowing down or using materials inefficiently. Some of the examples of smart manufacturing systems are computer-integrated manufacturing, high levels of adaptability and rapid design updates, digital information technology, and more adaptable technical workforce training.

Main benefits of technology adoption by manufacturers

If you are still unsure about the importance of technology in industrial manufacturing, here are some of the main advantages that your company can benefit from:

- Reduce human errors by investing in automation.

- Improve manufacturing efficiency by mostly increasing output and overcoming labour shortages.

- Invest in smart data that can recognise when it’s time for maintenance, allowing it to be scheduled.

- Improve productivity and help save on maintaining machines as it reduces time on repairing or replacing equipment.

- Allow tracking the final product and altering it to meet the needs of your customers.

8 Manufacturing Trends for 2022

To prepare your manufacturing company for the new challenging year, company owners, engineers and technicians must ensure the digital transformation. Especially popular in industrial manufacturing trends are still the Internet of Things (IoT), Big Data, and additive manufacturing (3D printing). The last one is still one of the most important trends in industrial maintenance.

But the technology is not stopping. This year we should welcome Industry 5.0, not Industry 4.0, shift from B2B to B2C and change offshore for onshore. There are plenty of new trends that will revolutionise the manufacturing industry in 2022.

1. Predictive maintenance

Predictive maintenance will be critical in assisting industrial companies in meeting rising customer demands and achieving digital transformation in 2022. Proactive maintenance has been shown to reduce unplanned downtime, increase the life of machines by years and save costs.

The majority of businesses today rely on a robust interconnected infrastructure featuring databases, hardware and software. These features are designed to help businesses streamline their operations and improve overall efficiency levels.

Dotto, The Cost of Downtime

Manufacturers can use predictive analytics to track equipment performance using a variety of performance parameters and automate the data collection process with IoT technologies. That helps them ensure that all equipment operates at optimal capacity levels.

2. Advanced automation

Automation is one of the key elements of modern industrial manufactures. Many tasks that formerly required human intervention can now be automated thanks to modern software programmes and robotics. The decrease of human involvement in repetitive and hazardous operations makes the manufacturing line safer and more beneficial for factories.

Industrial robots help companies speed up the working process and predict problems and flaws during the manufacturing process. Thanks to robotics, especially the agricultural and manufacturing industries benefit. As pointed out by Research and Markets during the period 2021-2027, the worldwide agricultural robotics market is predicted to increase at a CAGR of roughly 14.5%.

3. Industry 5.0

The improvement of many manufacturers was dependent on Industry 4.0, sometimes referred to as Industrial Internet of Things (IIoT) or smart manufacturing. There’s no questioning the Industry 4.0 impact on manufacturers in improving operational visibility, lowering costs, shortening manufacturing times, and providing superior customer service. It marries digital transformation of manufacturing, production and operations. And the revolution connected with Industry 4.0 hasn’t stopped.

Manufacturers can now even better utilize advanced tools and technological devices. The focus is moved from Industry 4.0 to Industry 5.0. Whereas the fourth industrial revolution focused on employing technology to optimise manufacturing methods, the fifth is all about connecting man and machine, or human-machine collaboration. Industry 5.0 is here and will certainly be present in 2022.

4. Artificial Intelligence

Artificial intelligence (AI) emerges as one of the most important manufacturing trends for solving the problem of quickly processing large volumes of data and extracting meaningful insights. AI helps industrial operations in many ways, including inventory management, supply chain visibility, warehousing cost reduction, asset tracking, forecasting accuracy, transportation cost reduction, and quality control.

Companies can get a lot of data from modern production equipment, such as process and performance statistics. When this data is properly analysed, it can reveal information about production optimization, maintenance scheduling, and asset management.

5. New recruitment strategies

Besides technological trends, also the way of recruiting new workforce can improve your manufacture. Manufacturing has faced an unprecedented amount of open skilled labour vacancies, in addition to supply chain shortages. Employers have to focus on providing flexibility and referral bonuses to employee retention. Also, make sure your company has a diversity of business personnel. This tendency will deepen in 2022.

6. B2B shift to B2C

Many manufacturers have switched from a traditional business-to-business (B2B) approach to a business-to-consumer (B2C) model in recent years. B2C increases profits, helps control brand and prices and provide better data. Thanks to B2C manufacturers can create, test, and push things to market quicker.

However, to reach consumers efficiently, companies need to choose an eCommerce platform that supports both B2B and B2C sales platforms. It must provide a visualisation of all the organisation’s B2B and B2C client contacts, as well as order fulfilment and tracking, secure payments, customer support management, and sales and marketing activity tracking.

7. Onshore not offshore

The pandemic has caused chaos on the global supply chain, making it more difficult for firms to get materials from other nations. Reshoring facilities and expanding their dependency on countries with which European countries have friendly trade agreements are two important trends they will have to address in 2022. As the costs of transportation continue to rise, countries should focus more on increasing sales on their lands.

8. Sustainability

The manufacturing industry has made climate change a top focus. It is now a commercial responsibility to manage operations in a sustainable and ecologically responsible manner. Many companies in the sector are already creating economically and environmentally sustainable business methods as the cost of energy and materials rise. Furthermore, regulations tighten, and customers and investors gravitate toward more sustainable brands and business practices.

Agriculture is responsible for around one-third of worldwide greenhouse gas emissions, prompting businesses to reconsider their business models and shift to low-carbon or carbon-neutral manufacturing processes. The green manufacturing tendency will continue as more manufacturers connect sustainability and profit.

Is your manufacturing ready for 2022?

Despite the difficulties mentioned at the beginning of this article, the industry is expected to grow. The most important is to initiate all the changes and reimagine the future of companies. Manufacturers should fully embrace industry 5.0 and be open to technologies. The main trends in industrial manufacturing are moving towards autonomic technology, B2C and carbon neutral. Besides that, important in 2022 will be accountability, AI, cybersecurity and focus on employee retention and diversity.

Preparing factories and employees for the changes, requires innovative thinking, careful planning, and modern systems. Help with it can Asset Operations Management. It’s a comprehensive solution that incorporates enterprise software at the top, as well as predictive analytics and machine learning technologies.

Recommended products

Digital Input Graphical Panel Meters, Red Lion

The latest NPI PM-50 series of panel meters are designed to increase operator productivity and expose critical plant floor data for use in project scheduling and process improvements. It’s the first devices to make the power of Industry 4.0 truly accessible, with smart device connectivity, the meters feature on-board wi-fi, rs-485/modbus, and optional ethernet or rs-232, with easy start up wizard and app for programming and monitoring.

CP2 Programmable Logic Controllers, Omron

Micro PLC CP2 series of Compact Controllers offers machine to machine communication with data collection thanks to built-in 2-ports Ethernet, control and machine monitoring is not only easy but also improves productivity and supports predictive maintenance.

I/O Module 16 DI Ethernet/MODBUS/TCP/EtherNet/IP, Moxa

These Ethernet-connected remote I/O modules with digital and analogue inputs and outputs are simple to connect, control, and monitor. Active contact with SCADA systems is supported using OPC. There are two Ethernet connections for convenient daisy chaining, and there is no need for a switch. With temperature sensors and digital and analogue input monitoring

The Acti9 iEM2000 series energy meters, Schneider

These power monitoring meters offer data measurement with Active energy Class 1 accuracy, LCD display, two tariffs, and MID approved technology, ideal for sub-billing and cost allocation applications, to lower cost of operation and optimise power efficiency. With the power management software, the Acti9 energy meters transform to a truly IoT digital power installation solution.

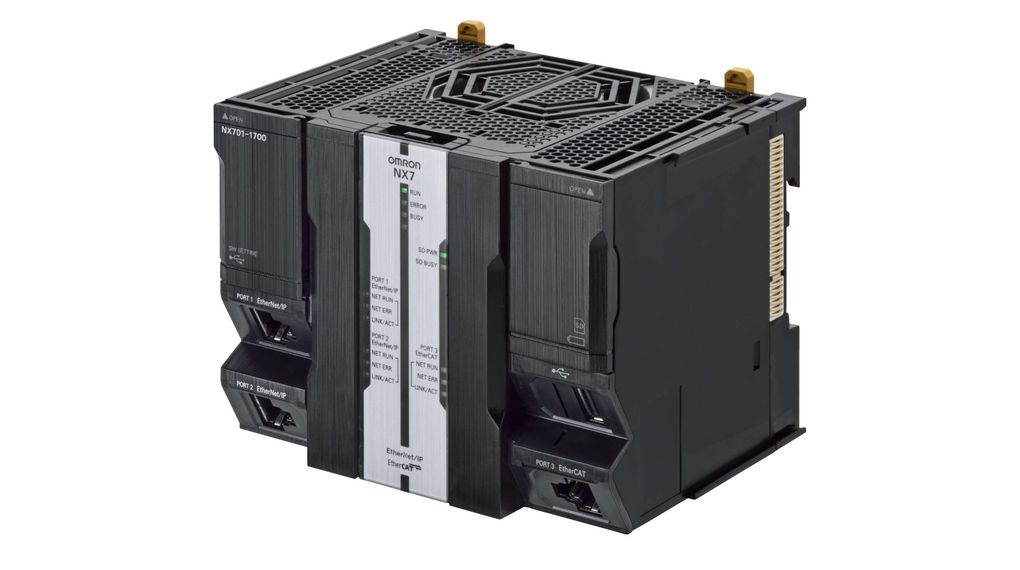

Sysmac NX7 Programmable Logic Controllers, Omron

These Artificial Intelligence Machine Automation Controllers, allows machine learning and optimisation on the edge with fast and accurate control by synchronizing all EtherCAT devices, such as vision sensors, servo drives, and field devices, and any anomaly detection to visualise error locations. NX7 AL Controllers encourage people-machine harmonious co-operation to make data-driven decisions, with just in-time maintenance and replacement, to minimize downtime and reduce production losses.

3D Printer, 2+ Connect, FFF, Open, Single, Ultimaker

The Ultimaker 2+ Connect is your reliable first step into the world of easy, remote 3D printing, with networking features and a new touchscreen. To get started, simply unbox and connect three components. It provides easy maintenance, next-gen components, touchscreen, enhanced safety and network connectivity.