Technology is probably the fastest growing medium in the entire world. In less than 50 years, high tech has grown and changed drastically. Considering the human’s constant need for development and progression, it became quite natural that the next step in developing technology was designing robots.

For decades robots were an exciting topic for philosophers, writers and movie producers to finally become engineers’ and AI technicians’ work. That began the creation of human-like machines. Robots are already here, ready to change ways of working and living.

Who brought robots here?

The origins of early modern technology can be considered the history of computers. Then, the internet and the transformation from cell phones to smartphones began. The development of technology opened up new horizons and possibilities. Now, the revolution goes even further by developing artificial intelligence, cognitive systems, robots and their collaboration with humans.

Starting from the etymology of the word ‘robot‘, which has been in use since 1920, its meanings are: ‘mechanical person’ or ‘forced worker’ (from Czech robotnik). Czech writer, playwright and critic Karel Capek, used it for the first time by calling his play ‘R.U.R.’ (‘Rossum’s Universal Robots’). It only proves that robots are ‘born’ as human inspiration so they can compete with us and… possibly win.

In many cases, jobs that used to be done by people are going to be able to be done through automation. I don’t have an answer to that. That’s one of the more perplexing problems of society.

John Sculley

The predictions about the impact that robots will have on society are positive or negative. That is true that computers made some jobs obsolete, but new IT and software jobs arose to fill the void. The development of robotics opens a new sector for humans to co-op with them. So will robots really be taking our jobs?

Robots in the workplace

Many manufacturers benefit from the new technology capabilities, such as automated production, smart data, IoT and machine learning. The robots in the world are mostly used in automotive and electronics assembly lines. They can undertake repetitive tasks and are programmed to perform specific functions including picking, packing and placing components.

Humans are performing worse, either through fatigue, poor posture while working, or the potential for respiratory harm. In contrast to people, robots can perform such tasks without breaks and with utmost accuracy, leading to higher quantities and a higher quality of finished goods.

Furthermore, robots can now handle activities that require a sense of ‘human touch.’ It happens by making robots more capable of feelings, for example, using force-torque sensors. They are able to handle grinding and polishing of non-uniform objects, a task a skilled operator would previously have undertaken. In such situations, there is definitely some cause for concern that robots could replace a human role.

According to a World Economic Forum report from 2020, 85 million jobs might be displaced by a shift in labour division between humans and machines. However, most sources ensure that Industry 5.0 will bring more jobs for humans than eliminate.

We have all become anomalies in the world of AI, but we have the power to triumph. If we open our minds and embrace the differences that make us human, we have a chance of preserving our humanity in the age of AI.

Ayanna Howard, Sex, Race, and Robots – How to Be Human in the Age of AI

How to use the new technology to grow your business?

Nobody has constructed properly functioning perpetual motion yet, but the robotics industry is growing, and robots have already impacted humans’ lives. Nowadays, a lot of manufacturers and factories are based on automation. Machines, unlike humans, don’t need to take breaks, and they can accurately perform repetitive tasks.

The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency. The second is that automation applied to an inefficient operation will magnify the inefficiency.’

Bill Gates

As communication in the world keeps changing, society now should be open for the fifth revolution in which the work between humans and robots will change the way businesses function. Robots will work alongside humans, complementing us in tasks that are generally not mentally demanding or too dangerous for humans to tackle. It means that the job will be possible to share and improve thanks to collaborative robots. Read below to see examples of collaborative robots used by industry leading brands.

Meet EVA – the industrial robotic arm

In the manufacturing industry, along with the growth of industry 4.0, popular become automotive robots undertaking repetitive tasks like EVA, the industrial arm robot. Eva from Automata provides machine tending, product testing processes, inspection and lightweight picking and sorting. Read more and listen to our Webinar about the robot EVA to discover its features, capabilities and applications.

OMRON’s robot built to work with people

The collaborative robot from Omron is designed to work with both humans and machines. It has a built-in vision system, and its integrated camera localises objects in a wide field of vision. Because of technologies like force feedback, low-inertia servo motors, elastic actuators, and collision detection technology, collaborative robots are built to function safely with human operators. Thanks to that, businesses can attain better efficiency while ensuring workplace safety.

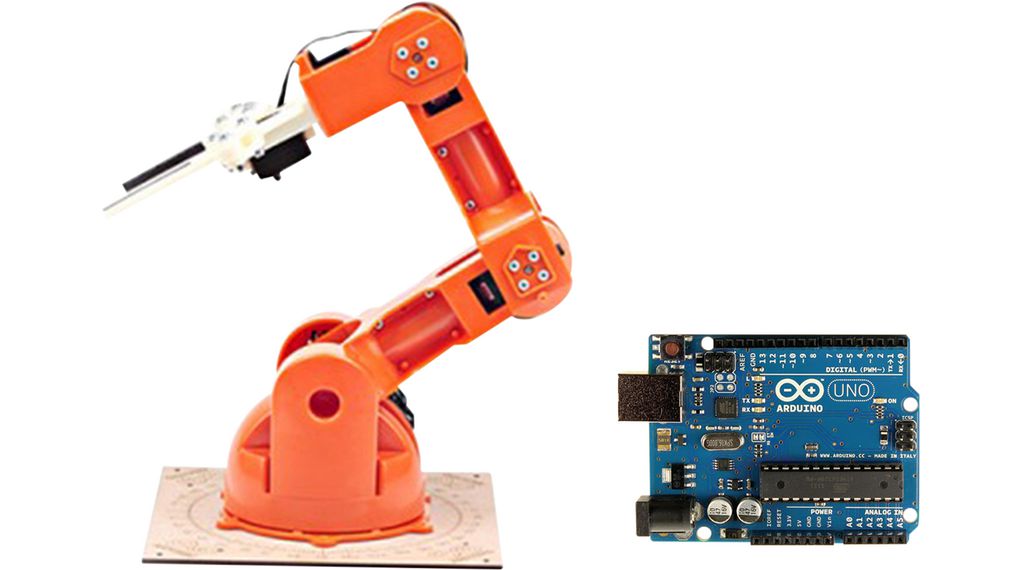

SparkFun uARM Swift pro robotic assistant

The uArm Swift Pro from SparkFun is an open-source and DIY friendly robotic arm platform intended for makers and educational purposes, based on an Arduino Mega 2560. It is a high-performance desktop robotic assistant with far more uses than its predecessors.

ABB’s YuMi dual-arm collaborative robot

In 2015 ABB introduced YuMi, a robot that combines people’s unique capacity to adapt to change with a robot’s tireless endurance for precise, repetitive operations and the ability to automate the assembly of multiple goods on the same lane. According to the brand, YuMi is ‘designed for a new era of automation’.

6 industries that use robots

Everyone uses robots in their everyday lives. Scientists, engineers, or medics use robots to facilitate and improve their work. These examples can be artificial intelligent apps, cooking robots, defence robots or servants.

Manufacturing

Manufacturing is one of the largest industries where robots are used. Robotic manufacturing technology is also safer to operate. With cameras, sensors, and automatic shut-off capabilities, the workplace can be more sustainable and easier to operate with advanced technologies. Advanced automation and industry 5.0 are some of the industrial manufacturing trends for this year. If you are interested in improving your plant, find out more about smart factories changing the manufacturing industry.

Agriculture

Similarly to manufacturing, in agriculture, robots increase productivity by lowering overall costs and adopting different forms of robotic technology. Check how the growth of technology and investing in automation is improving the agriculture industry. Farmers are already using self-guided GPS tractors, harvesters, and robots to replace labour shortages.

Online Support

The online support provided by robots, often called chatbots or voice-activated personal assistants, are capable of a certain level of natural language understanding. They can answer many mundane questions while also being able to forward questions that require human interventions. An example of that intelligent voice operating system type can be ‘Samantha’ from Spike’s Jonze Her. Even though it is a science fiction movie, many people communicate with Alexa and Siri, intelligent voice operating systems. From a business side, companies invest in such robots internally to handle IT support queries.

Medical Robots

Another common area where robots play a big role is medicine. Medical robots are well known, especially in surgery, like the da Vinci robot, which accompanies surgeries by helping patients to lose less blood, reduce risk of infection and speed up healing. The collaborative robots effectively replace a member of staff during such procedures. However, this also frees up that resource for the other tasks required of a medical professional while also reducing the cost of medical interventions.

Still, the question is if patients will accept robots being more common and which are better – the ones similar to people or not? If all of them looked like ‘Baymax’ from the Big Hero 6 movie, no one would have anything against them.

Food preparation

Could you imagine a robotic waiter, chef or bartender like in Morten Tyldum’s movie Passengers? Automated and intelligent robots will be able to prepare and cook hundreds of meals. We already use some kitchen robots that help us prepare some meals quicker and without interventions.

Military

Robots are common help in the military as well as public safety sectors. For example, unmanned drones can be used for surveillance and support operations on the battlefield. These military drones in hostage situations can access danger levels and provide soldiers and first responders with real-time information.

The future of robots and humans

As mentioned above, robots surround us already. They mostly improve people’s work and broaden their horizons to explore new technological capabilities. That also creates new job opportunities. Comparing previous industrial revolutions, it doesn’t seem like there is a risk that robots will take our jobs.

The development of automation in Industry 4.0 proved already that we can work along with machines and improve efficiency and quality. The fifth industrial revolution is supposed to bring the collaboration between people and robots where the focus on producing for individuals will replace mass production.

Will the reality be like science-fiction movies or books, we will find out soon. Some movies present a sort of catastrophic vision of robots like in Alex Garland’s Ex Machina, where the AI wins over humans. The creator of ‘Ex Machina’ says: “One day the AIs are going to look back on us the same way we look at fossil skeletons on the plains of Africa. An upright ape living in dust with crude language and tools, all set for extinction”.

However, movies are not always what we see in reality, but science-fiction technologies are already here. And the designers and AI engineers go even further and try to create machines that look almost like humans. Answer yourself: does this mean competition?

Recommended products

Arduino Tinkerkit Braccio Robot Arm

The BRACCIO Robot Arm is possible to assemble in a variety of ways. The servos can be easily connected to your Arduino board using the accompanying BRACCIO shield. With its adaptability, the BRACCIO can also support a variety of things on the end of the arm. Its load capacity: Maximum weight at 32 cm operating distance: 150g.

uArm Swift Pro Robotic Arm 12V, SparkFun Electronics

The uArm swift pro robotic arm is small and so simple to use that practically anyone can pick it up in a few minutes. It is an open-source and DIY friendly robotic arm platform intended for makers and educational purposes, based on an Arduino Mega 2560. Visual programming and Arduino, Python, GRABCAD, and ROS programming are all supported by the uArm, giving users a wide range of possibilities.

EVA – Lightweight 6-Axis Industrial Robot Arm, Automata

EVA is the world’s first desktop robot, built from the ground up to be low-cost, lightweight, user-friendly, and accessible while still delivering industrial-grade capability. Eva is a six-axis industrial robot with a reach of 600mm and a payload of 1.25kg, making it ideal for pick-and-place, testing, inspection, and machine tending.

Petoi Bittle Open Source Robot Dog Kit, Seeed Studio

Bittle is a little robot dog who is fast and powerful. It’s an excellent tool for learning about quadruped robots, as well as teaching and researching them. Using a customised Arduino board that coordinates all instinctive and sophisticated movements, you can clip on numerous sensors to bring in perception. You could also use a Raspberry Pi or other AI chips to add artificial intelligence capabilities.