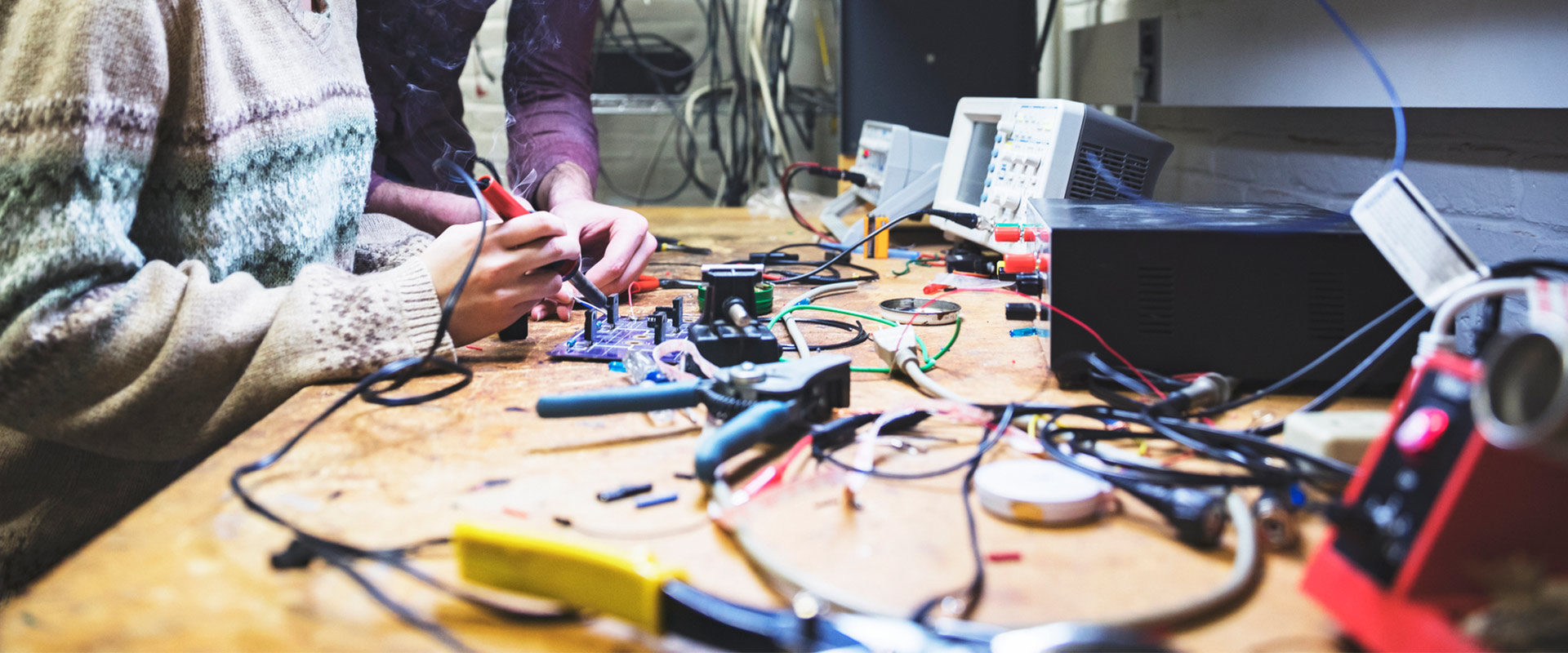

We know that soldering successfully requires a mixture of both skill and the right, reliable equipment. In today’s world, where pricing and quality is key, we can help you chose the right tools for your applications, helping you to keep costs down, while maintaining high quality and industry standard compliance.

Crucial in electronics, whether it’s to repair, maintain or solder your own circuits, solder is important to mechanically and electrically link two metal surfaces. It connects electronic components, preventing them from breaking due to vibration or other mechanical forces, while allowing currents to flow and allowing electronic signals to move uninterrupted through the connection.

It is important to choose the right equipment and materials, and when choosing RND, you can be sure to find the solution you need, whether it be soldering stations, irons or bundles to help you do your job, all whilst saving some serious budget.

Our Favourite Soldering Tools

When soldering electronic connectors, there are some important pieces you need, including:

- A reliable soldering iron or station.

- Solder wire (with or without a flux core).

- Flux (if the wire solder does not have a flux core or if more flux is needed).

- Tools and aids.

- Clean workspace with fume extraction.

Besides this crucial apparatus, soldering effectively requires the right tools that will make the whole process easier and safer.

Have a look at our list of top soldering tools:

Soldering Station

A soldering station includes the technology that can provide key information about the temperature of your iron and tip. Working with a soldering station is far more convenient and reliable than working with a soldering iron alone, as it gives you more accurate data as you work.

Soldering stations are well-equipped, they provide precise temperature that you can pre-set before the soldering process. This temperature does not alter throughout. Many prefer a station over an iron, but there are many uses for both.

RND also has a soldering station with a fume extractor, saving you space on your work bench, without forfeiting safety. With continuous variable temperature control, fast heat recovery and an ‘active carbon’ filter. Check out our preferred RND device here:

Recommended products

Soldering Station with Fume Extractor 60W 450°C 240V, RND Lab

The RND 560-00160 Temperature Controller Soldering Station with Fume Extractor allows for continuous temperature control, has fast heat recovery and a high performance ball bearing fan. It is in compact size to be easily positioned ensuring maximum effect.

Soldering Station 100W 500°C 230V, RND Lab

The high-power, temperature-controlled soldering station with microchip controllers was created to fulfil the current and future lead-free soldering needs of the electronic manufacturing industry, and is appropriate for professional SMD electronics work. It has all of the advantages of temperature regulation and connects via a highly flexible burn-resistant lead that can be altered in temperature (tip temperature from 100 to 500°C).

Multimeter

An auto ranging multimeter is helpful to have to hand whenever you begin your work.

We recommend an auto-range multimeter, such as the RND True RMS Autoranging Digital Multimeter. It will save you time and minimizes the measurement error.

To find out more about multimeters, read this multimeter guide to choose the perfect one for various applications.

True RMS Autoranging Digital Multimeter 1kV 10MHz 50MOhm, RND Lab

RND offers a comprehensive choice of This product enables you to accomplish your basic test and measurement requirements on a budget. The true RMS autoranging digital multimeter is a small and portable device. The multimeter measures AC/DC voltage, AC/DC current, continuity, diode test, frequency, impedance, and resistance. The measured data can be also stored in cloud services.

Hand Tools

A strong and reliable tool is a must-have for all engineers. RND have pulled together a large range of hand tools which we think should belong in every tool bag or on every work bench. From Strong Cutters and screwdrivers, to delicate tweezers, reverse action tweezers and helping hands to help hold your components and save burning your fingers.

We recommend the RND range because, not only you will get value for money, but a tool you will rely on for years.

PLCC Extraction Tool, RND Lab

Kit of 6 ESD Epoxy Coated Tweezers, Stainless Steel, Curved/Grooved/Sharp/45° Angled, RND Lab

PCB Holder with Magnifier 150mm, RND Lab

Tweezers

RND Tweezers can help you handle materials and prevent from burning fingers. Especially, when soldering delicate items, reverse action tweezers are designed to retain components in position and prevent soldering burns on your fingers.

SMD Soldering Iron Tweezers and Tips Set 100W 430°C, RND Lab

Light and compact soldering iron tweezers are perfect for fast and efficient soldering and desoldering of SMD components. Features: fast heat-up time, nichrome heater, 100W output power, 32VAC and 430°C maximum temperature.

Magnifying Glasses and Lamps

These tools enable the finding and lighting of microscopic junctions between pins that aren’t supposed to be there, and will help in any general PCB work with small components and fine solder.

- LED Magnifying Glass Lamp with Table Clamp, RND Lab

- USB Magnifier Spectacles & Headband, RND Lab

- Handheld Magnifier with Inbuilt Stand, RND Lab

Storage

The wall storage systems, wall boxes or wall-mounted enclosures, are safe enclosures attached to the wall in your workspace for easy access. If you are building a lab, we think that the RND wall storage system is crucial to ensure access to the right tools and components, when you need them.

Carrying around your tools and components will also need a robust and secure case or bag. We have great vale options available

Wall Mounted Storage, 26 Pieces, 635x380x19mm, RND Lab

These RND wall mounted storages are built from hard wearing plastic. They have convenient and moveable trays and hooks. The panel board contains: 10 plastic hooks and 15 different sizes bins.

Solder Safely with RND

Soldering can be hazardous for your health. Before starting any of your soldering applications, it is an obligation to know the safety rules. The safe soldering techniques require respecting soldering safe work procedures, including PPE (personal protective equipment), health surveillance, general safety precautions, maintenance, examination and testing, equipment and procedures.

Solder with lead is regarded to be toxic without proper handling. Workers may be exposed to lead-containing soldering material. However, when the solder is handled and managed properly, there is very little risk to anyone who works with it. Although, ingestion of lead from surface contamination and inhalation of soldering fumes are two potential exposure pathways from soldering. Lead (Pb) is a known neurotoxin that can cause various long-term health concerns, including reproductive issues, digestive issues, memory and attention issues, and muscle and joint discomfort.

Soldering rules in brief:

- Ensure you know the Engineering Health & Safety rules for your country.

- Wear eye protection.

- Never touch the element of soldering iron.

- Tweezers or clamps should be used to heat wires.

- Always put the soldering iron back on its stand when finished working (it should never be placed on the workbench).

- Turn off the unit and unplug it when not in use.

- Make sure to wash your hands with warm water and soap after application.

- Use proven equipment from professional brands.

Safety equipment

If you have already got acquainted with Soldering Safety, prepare your workspace before starting any applications. A suitable workspace is one of the most important factors that ensure safety.

We recommend creating a clean, dust-free space with plenty of worktop space, protecting with a heat-resistant underlay/mat for your table, workbench, a small vice and workholder. These tools, when properly positioned, keep the component to be soldered in place during the soldering process, preventing it from slipping and allowing it to cool down after soldering.

- Self Healing Cutting Mat A1, RND Lab

- Adjustable PCB Holder / Repair Platform, RND Lab

- Work Holder, RND Lab

- Multi-Angle Bench Vice, RND Lab

Ensure that the tools you plan to use are clean and without residue. And if any of your components contain surplus materials, you can use fine sandpaper, files or sprays to remove grit and flux.

- Medium Cut Double Ended Riffler File Set, RND Lab

- PCB Flux Remover / Cleaner, RND Lab

- Microfiber Wiping Cloths, RND Lab

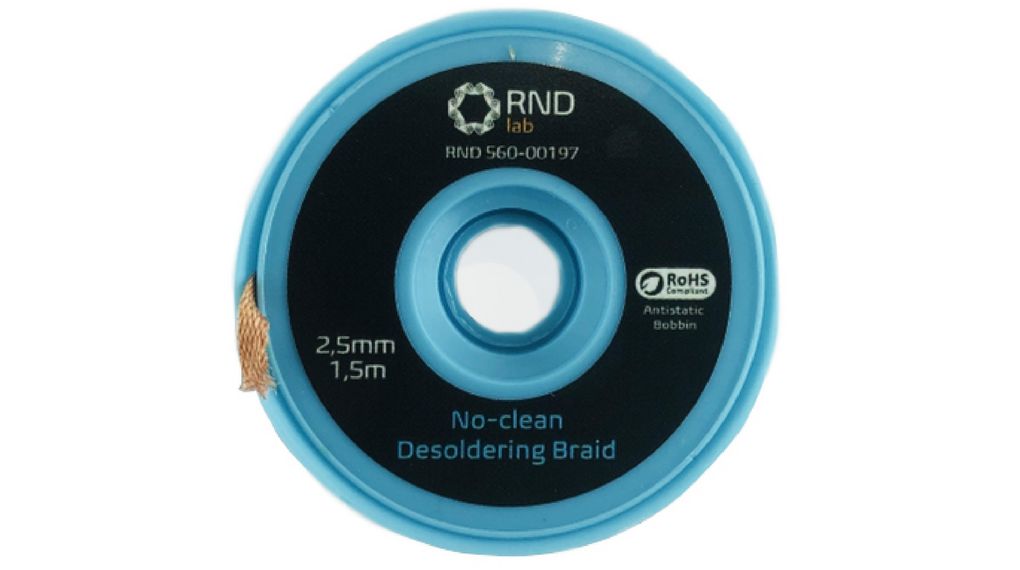

Desoldering

Remove hardened, old solder from a previously soldered component, or joint or surface. With the right equipment and expertise, this can be done using a regular iron – but, RND has a number of useful tools and desoldering accessories for helping to make that task job much easier and neater.

Hot Air Station 1.3kW 500°C 230V, RND Lab

Desoldering Braid 1.5m 2.5mm Blue, RND Lab

Desoldering Pump 194mm, RND Lab

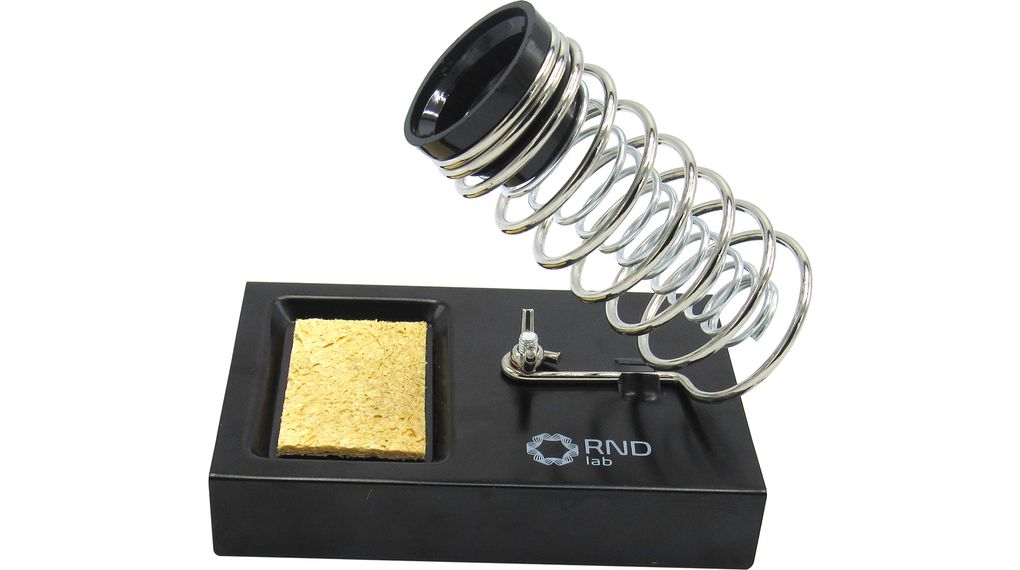

Cleaning Tools

Cleaning the soldering iron tip is key. Because the tip is heated, it will oxidise quickly and become difficult to work with. A clean tip transfers heat more quickly and simplifies soldering.

Soldering Iron Holder with Sponge Rest, RND Lab

The soldering iron holder with a sponge (54 x 34 mm) is robust and stable. The spring holder length is 100 mm, centre hole diameter 23 mm and inner cup diameter 32 mm. This item will help you ensure the safety of working with soldering iron.

If you are looking for something different, in RND Lab offer there are also brass wool with tray and soldering tip cleaner.

Face and eyes protection

Masks help prevent inhaling some of the oxide coming from, for instance, flux. How can this become harmful vapour? During the soldering process, flux is contained within a soldering wire that leads to the components being soldered. The flux is released and evaporated as the solder melts. Particle filtering face masks, or solder vapour extraction systems with an integrated filter, like solder fume extractor, offer a solution in this situation. Search for safety equipment from RND and choose a variety of different sizes and pricing ranges.

In the topic of eye protection, when soldering small parts under a microscope, safety glasses are normally not required, although the objective lens may be shielded with a clear shield. If you set up the correct temperature, the solder rarely spatters, but rarely it is not the same as never. If you get hot soldering in your eye, the effects can be terrible. Therefore, we highly advise wearing any glasses but the best soldering safety glasses, goggles, or face shields. If you cannot decide, RND safety goggles will be perfect.

Safety Goggles, Clear, Anti-Fog/Anti-Scratch, 72mm, RND Lab

The impact-resistant, anti-scratch and anti-UV are perfect solutions to protect your eyes against any damage. They fit fully to the face and eyes and are ideal for tough work environments. The main applications: engineering, light duty maintenance and repair work, construction and laboratories.