The Internet of Things (IoT) connectivity describes the interconnection of every component of the IoT ecosystem, including sensors, gateways, routers, platforms, applications, and other systems. It frequently refers to various network systems that are categorised based on the bandwidth, range, and power needs.

The requirements for IoT projects vary, and many use various connecting methods. Thus, choosing the right solution for your asset might take time and effort. Luckily, there is Industrial Shields, a brand with an important portfolio dedicated to the Internet of Things and the Industrial Internet of Things (IIoT). Industrial Shields provides plenty of solutions to connect and monitor your factory plant.

Connectivity challenges

Before going through the solutions, you have to be aware of the challenges that connectivity brings. One of the main obstacles facing organisations is the adoption of emerging technology. Having a thorough awareness of the industry is crucial, even though it is nearly impossible to stay current with everything. Companies may monitor data in a variety of ways with the help of an outside partner or, depending on how important it is to them, mainly through closed solutions that can be customised, repaired, upgraded, etc.

You may select open-source based solutions, where you will own the entire system and have control over things. Then you can decide what you want to monitor, how frequently and where you want the data to be sent or stored, etc. All of this comes at a far cheaper acquisition cost because of savings on licensing, consultancy fees, and third-party programming.

In order to choose the ideal connection network for your smart organisation, you must be able to recognise your project’s requirements at every stage of its deployment and have a thorough understanding of IoT.

IoT Connectivity Solutions

The Internet of Things is a massive technology that combines the digital and physical worlds to provide a wiser future and continues to draw market participants and investments due to its almost endless potential. However, since cellular, Wi-Fi, and Bluetooth are already widely used wireless technologies, many people overlook the significance of getting their IoT connectivity right. But IoT is a crucial implementation to a properly functioning enterprise, especially in smart factories.

Therefore, with the help of Industrial Shields, we will showcase solutions to help you control and connect your assets properly.

IoT and PLCs

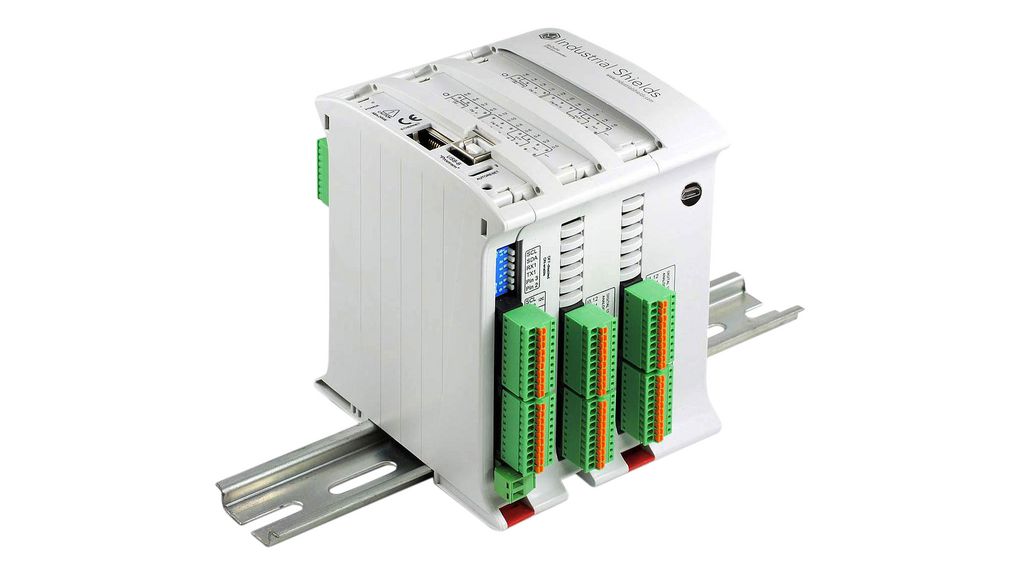

Industrial Shields designed a great portfolio dedicated to the Internet of Things technology, among others, advanced PLCs and other devices that are enriched with Arduino, ESP32 and Raspberry Pi technologies. IoT and IIoT solutions cover a wide range of possibilities. Below we briefly explained some of them.

IoT greenhouse

IoT farmers can gather various data points in the greenhouse with previously unheard-of granularity thanks to IoT sensors. This enables monitoring and control of crucial climate variables like humidity, temperature, irrigation, light exposure, amount of CO2 and soil moisture. Users can preserve the greenhouse’s perfect performance and condition by keeping an eye on the plant’s state and keeping track of any incidents or failures that may have occurred and their intensity.

The Industrial Shields’ Arduino range of PLCs, together with Open Mote, which is an open-source prototyping platform for the Industrial IoT, and Panel PC, has been installed in a greenhouse of about 20,000 m2 to monitor and automate various processes. All the sensors have been connected to the network through the Open Mote installed. Also, several Arduino PLCs and Touchberry (Raspberry Panel PC) have been connected to this same network, allowing for monitoring of constant and correct parameterisation.

Watch the video below to discover how to monitor and control multiple I/Os with the Industrial Shields’ Arduino PLC and Raspberry Pi Panel PC.

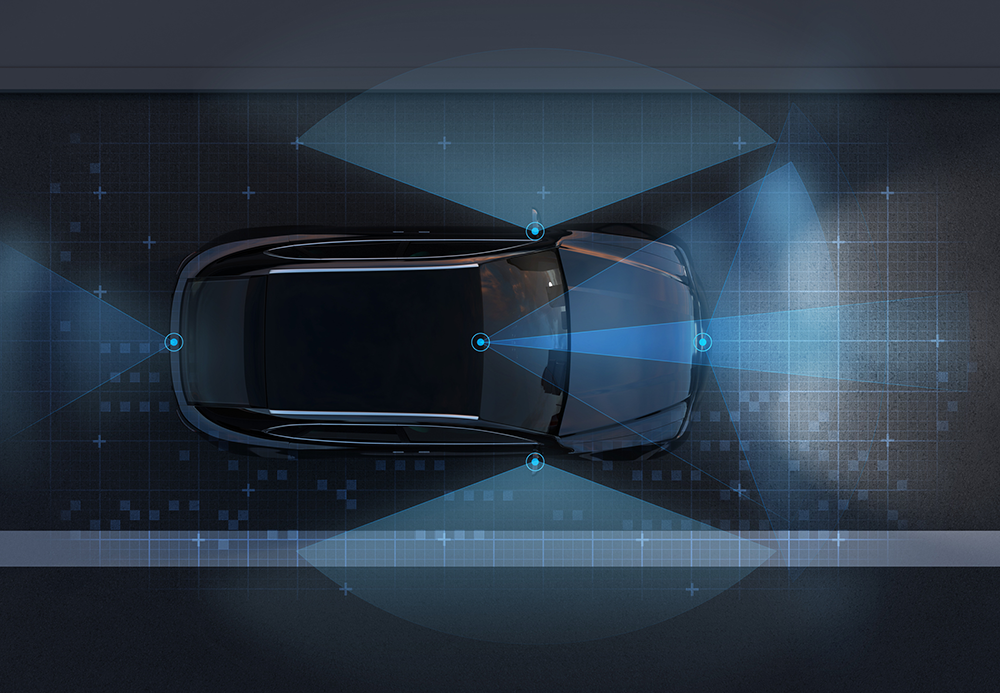

Automotive IoT

IoT is broadly used in the automotive industry, connecting devices, such as sensors, cameras, and GPS trackers that are linked to the cloud and give real-time data for improving both the manufacturing and transportation processes of cars.

Industrial Shields’ Raspberry PLCs have been installed in hundreds of car wash’ washing tunnels to be able to monitor their status, whether operating or stopped, and the causes of the stoppage: out of service, failure, or maintenance.

Multiple sensors have also been installed in order to track the energy consumption (in parts of motors, pumps or compressors, water consumption, soaps, etc.) of the various car wash tunnels in real time and to collect data in aggregate.

You can monitor the service offered by the various car wash tunnels because the equipment is connected to the network. You can use it to check for malfunctions and leaks of energy, water, or consumables. Moreover, where and at what cost are the resources required for the tunnel to function being reduced. This will allow for an analysis of each car wash tunnel’s economic viability.

IoT in assets and inventory

In the warehouse, connected sensors monitor every asset on the property. Smart shelves may alert warehouse managers to low stock, misplaced goods, inappropriate temperatures, theft, and other issues by showing inventory information.

Industrial Shields designed the installation of Open Motes and ESP32 PLC that allowed for monitoring the environmental conditions in a logistics warehouse of about 100,000 m2, besides often changing environmental conditions.

Which IoT Communication Protocol is Suitable for your Project?

Each IoT communication protocol has unique qualities that make it appropriate for some projects while rendering it useless for others. The range, memory requirements, power requirements, installation costs, and other characteristics of protocols vary widely. Some can communicate across physical barriers, while others can only connect devices inside one building. For instance, Bluetooth, a popular smart home, fitness, and healthcare IoT communication technology requires little power and memory to run, but its connection range is limited.

Software for IoT solutions

Industrial Shields provides PLCs with Wi-Fi, Bluetooth, DALI, LoRa, and other technologies. As the brand claims, ‘One link will be better and more appropriate than another depending on the company’s objectives’. As an illustration, the RS-485 communication protocol is used to send data at a fast rate of speed over distances of up to 12 metres.

One of the many uses for Industrial Shields products is utilising a PLC to determine the present or anticipated local temperature. It is an application that is widely used and provides a solid proof-of-concept. In this instance, a PLC has been configured using the necessary HTTPCMD and JSONPARSE directives.

The brand has developed dedicated Industrial Wireless LAN (WLAN) devices to meet the unique requirements of Wi-Fi in the industry in order to provide businesses with the best infrastructure for sharing data of all types.

ThingsBoard

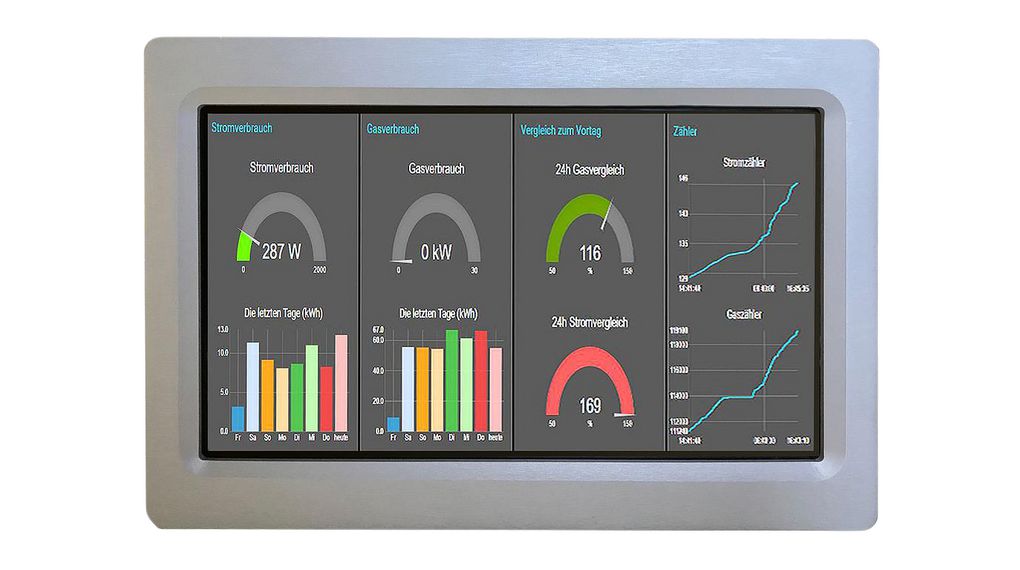

MQTT, CoAP, and HTTP are the three widely used IoT protocols that enable device connectivity, and both cloud and on-premises deployments are supported. ThingsBoard is an open-source IoT platform for managing devices and collecting, processing, and visualising data. You won’t ever lose your data thanks to ThingsBoard’s combination of scalability, fault tolerance, and performance. Several of the Industrial Shields monitoring solutions are based on this open-source IoT solution. It is a great advantage for customers as they can save on licensing costs and benefit from flexibility.

MQTT

MQTT is an OASIS standard messaging protocol that is intended to connect remote devices with a very small code footprint, and little network bandwidth using a publish/subscribe messaging transport. Today, MQTT is currently utilised in a wide range of sectors, including automotive, manufacturing, telecommunications, oil and gas, etc.

Industrial Shields used an MQTT communication protocol in the presented above solutions. It is designed as an extremely lightweight publish/subscribe messaging transport that is ideal for connecting remote devices with a small code footprint and minimal network bandwidth.

Firmata

Firmata is a standard protocol that enables software running on a host computer (such as Panel PC) to communicate with microcontrollers (such as Arduino). This protocol can work as firmware in any Microcontroller architecture and also as software on any host computer. In essence, this firmware creates a mechanism for the host programme to communicate with Arduino. The goal is to make it possible for users to fully control the Arduino via host computer software.

Emoncms

Emoncms is a powerful open-source web application for processing, logging and displaying energy, temperature and other types of data. Using Emoncms, you can display on a web server what is happening in an Arduino PLC. It’s also possible to display diagrams and compare data to get better feedback from an installation. You can visualise the data on a computer, tablet or smartphone.

Node-RED

Node-RED is a flow-based programming tool for the Internet of Things, connecting hardware devices, APIs and online services in new ways. It offers a browser-based editor that makes it easy to wire flows using the wide range of nodes in the palette that can be deployed in your runtime with a single click.

Why choose Industrial Shields?

Manufacturing high-quality and high-performance industrial PLCs with Arduino, ESP32, and Raspberry technology has taken open-source based hardware to a new level for Industrial Shields. You can replace a conventional PLC with an open-source based programmable logic controller for any automation applications.

When choosing Industrial Shields’ devices, you can have an open solution with no licensing costs. Reach for equipment that is created and produced for industrial automation. If you wish to have a modular design, the project may be expanded in the future. Aside from that, Industrial Shields provides good pricing, superior service, and technical support.

Recommended products

Programmable Logic Controllers, M-Duino, Industrial Shields

Programmable Logic Controllers, ESP32, Industrial Shields

Touch Panels, Industrial Shields

Programmable Logic Controllers, Raspberry PLC, Industrial Shields