James Prietzel, Product Manager at Intelligent LED Solutions (ILS)

James is the ILS Product Manager for everything related to LEDs and has been with ILS since 2012. James is dedicated to understanding the latest technologies and innovations from leading suppliers in the OptoElectronics world, from optics, to LEDs and to Intelligent LED Drivers.

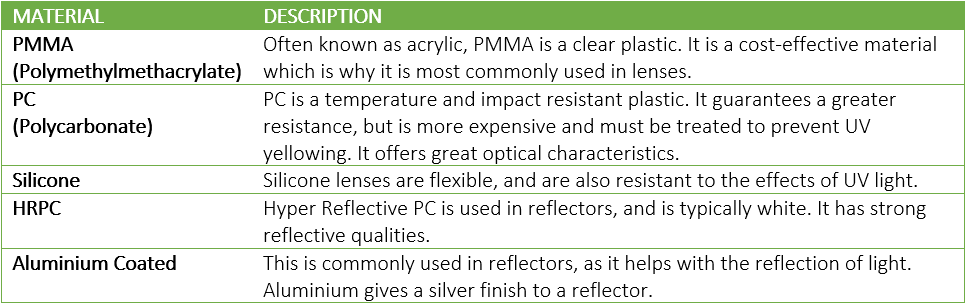

An LED’s primary optic only tends to emit directional light at 120°, but this is not suitable for all applications, and therefore can cause lighting to lack intensity over distance. To get an LED to produce light in the desired way with a more focused intensity, it is necessary to use a secondary optic. These work to concentrate or diffuse the light emitted. Lenses for LEDs are commonly made from polycarbonate (PC) or polymethylmethacrylate (PMMA).

Depending on the material they are made form, they can either be rigid or flexible. The best material to use is subject to the end application, for example if the application was using UV light, you would require a silicone lens, as this is resistant to the side-effects that can be caused by UV light.

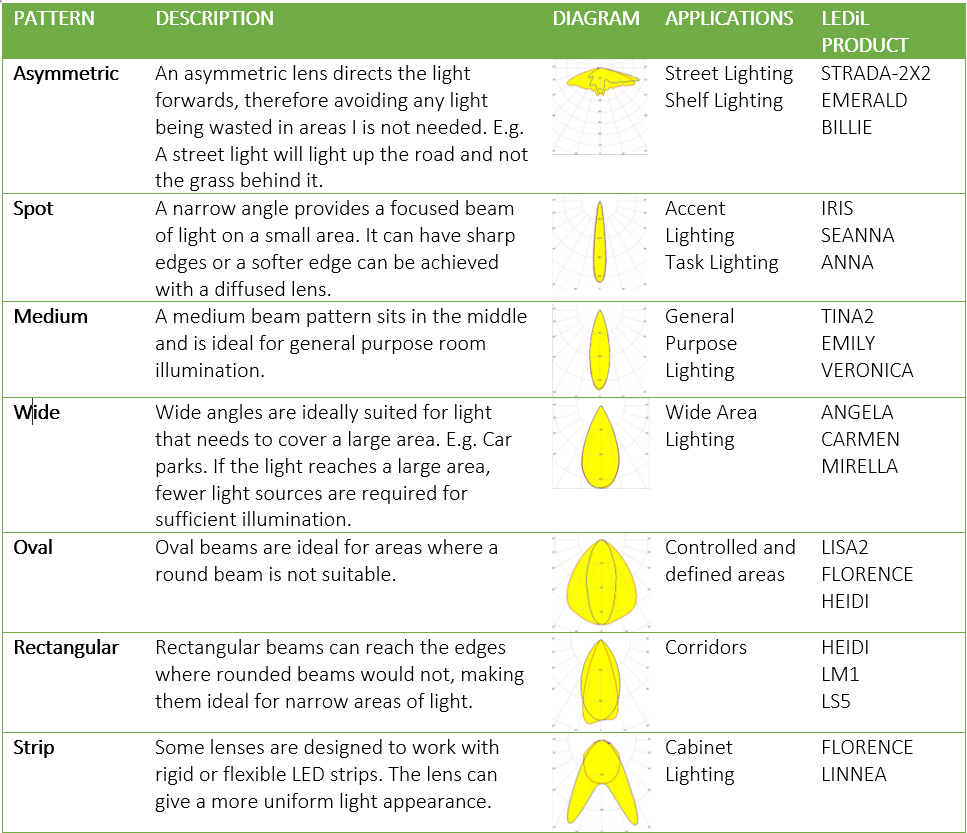

LED optics come in a variety of shapes and sizes; Lenses can be square, round or hexagonal, while reflectors are varying cone shapes. They can be designed for both use on single LEDs or for LED modules containing multiple LEDs. When used on an LED module, a lens can give a more aesthetically pleasing appearance by concealing the LED components within. A lens sits over the LEDs to produce the desired lighting effect, and enables precise control over the light emitted.

Using lenses and reflectors, means that the creation of different beam angles is possible. Narrow beam angles, e.g. 60°, have a focused and concentrated beam of light which is well suited for spotlights. While wide beam angles e.g. 150°, have a larger coverage for illuminating a wide area.

There are different variants of secondary optics for LEDs, these include diffusers, reflectors and lenses. All of which work to alter the path of the light in a specific and controlled way, but all creating different effects.

Diffusers:

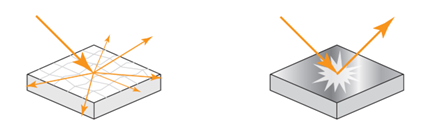

Diffusers can be made of various kinds of material, but all have the purpose of diffusing and scattering the light. The light passing through the material bounces between its atoms and spreads. This occurs by the material absorbing and scattering some of the photons which reduces their energy, thus causing an attenuation of the luminous intensity, and a more even spread of light. The intensity of the diffusion all depends on the type of material used, its thickness and surface treatment.

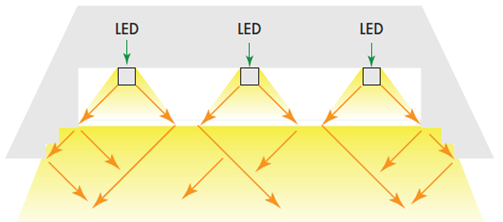

Furthermore, diffusion can give a more uniform light output when multiple LEDs are used. Lenses can also be diffused, creating a softer edge and more even spread of light, whereas clear lenses provide a crisp-edged beam of light.

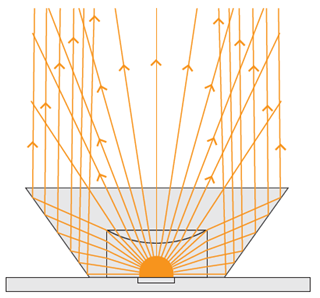

Reflectors:

Reflectors are made using plastic and can be metal coated, which sit over an LED to alter the beam of light. LED Reflectors come in various different shapes and sizes, with the inside surface being either smooth or multifaceted – this enables them to create a range of lighting effects.

They are a cost-effective and easy to implement solution. How they disperse the light is dependent on their shape. Typically, for a narrower beam, a bigger optic will be required. Some reflectors can even contain a sub-lens, for additional diffusion or control of the light.

Reflectors are used in the majority of incandescent lights, but with LEDs there is one main disadvantage; they do not offer as much control as an LED lens, because the many light rays emitted from the centre, will pass out of the system without making contact with the reflector. So even with a narrow reflector, a portion of the light will stray wide of the target. This can mean that there is glare created and even lost lumen output.

Lenses:

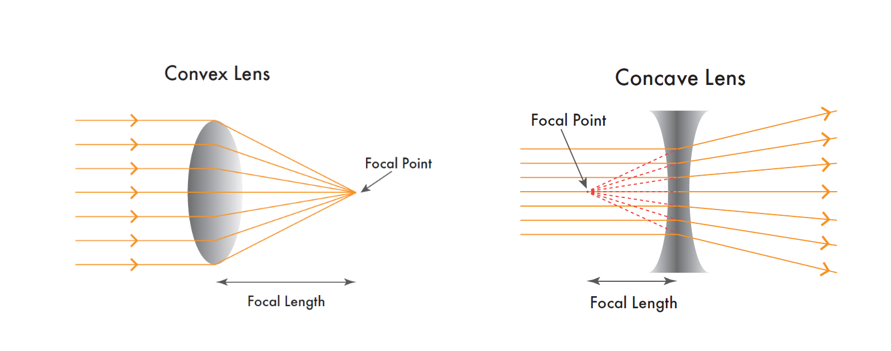

An LED lens works by the basic principle of refraction; it distorts beams of light as they travel through the lens, specifically directing the light as required. A lens can be convex or concave.

A convex lens has a surface that curves outward and will make parallel light rays converge at a focal point. Whereas a concave lens has a surface that curves inwards, making parallel beams of light curve outward, away from a central point. x

A lens that uses a combination of two or more simpler lenses is called a compound lens. By combining convex and concave lenses, it is possible to make lens that behaves in more complex ways.

There are a great number of advantages to using secondary optics with LEDs. Secondary optics successfully collimate light rays into a controlled beam, therefore allowing the user to direct the full intensity of the light emitted by the LEDs onto the desired area. Overall a lens gives better control of the light, and a higher and more direct intensity. Furthermore, they allow for better energy efficiency as less light is wasted and lost on other area. Lenses also reduce unwanted glare and help distribute light in a more seamless and pleasing way.

LEDiL precision-engineered lenses and reflectors allow for rapid deployment of all types of light fixtures, including street lights, wall-wash, high-bay, sconces, emergency beacons, parking garage/low-bay, MR and AR downlights, dock lights and horticultural lighting. Precision-engineered for maximum efficiency and durability,

LEDiL lenses and reflectors are released alongside the latest product releases from our LED suppliers. ILS are a franchised distributor and solutions provider for LEDiL product.