Ensure the continued performance of your switches as you integrate industrial automation into your operations

For decades, the production-oriented factory floor operated independently on fieldbuses, while the IT world focused on Ethernet networks. These two isolated networks used different protocols and had different purposes, neither knowing (or being affected by) the other. This approach worked well at one time. It allowed IT to focus on the security and accessibility of the office, while OT focused on the safety, reliability, quality and availability of production. However, Ethernet has found its way into the world of industrial applications.

The technology and platforms used in OT became more similar to those used in IT. When IT and OT come together we talk about IT/OT convergence.

Explore additional IT/OT insights by download our White Paper to “Successful IT/OT Convergence”: https://www.belden.com/Resources/successful-it-ot-network-convergence

But the factory floor continues, and avoiding downtime is key. And while you are integrating automation into your processes, adding devices and collecting data, you also need to make sure your industrial switches are up to the job.

In the past, industrial networks had little or no security. But as data began to move across an industrial grid, switches had to become more sophisticated. But if there aren’t regular software updates available, and your facility falls victim to a security breach or cyber-attack, your insurance provider may refuse to pay out if it discovers that the security of the hardware has not been maintained. This means that security updates are not just a matter of protection – they’re also an insurance requirement.

Redundancy is another example of functionality provided by an industrial switch. If the primary network equipment fails, the secondary equipment takes over to keep the application running.

In comparing basic unmanaged and high-performance industrial switches, certification should be considered. For example, the manufacturing and industrial sectors rely on IEC 62443 to help secure critical infrastructure.

When deciding on a new switch, you need to evaluate cost and feature differences to find the best fit for your environment and application.

If you transmit sensitive data and security is paramount, choose a managed switch to restrict network access to trusted devices and authorised users. You can also control traffic to allow important information through, protect against outages and control access to individual ports. However, in some industries, it is preferable to opt for high quality unmanaged switches, which are fast, simple and cost-effective components that only need to be ‘plug and play’ to connect any additional devices to your network.

Hirschmann Switches (a Belden Brand) are independently certified according to IEC 62443-4-1 ensuring full security and operation excellence from the very first day.

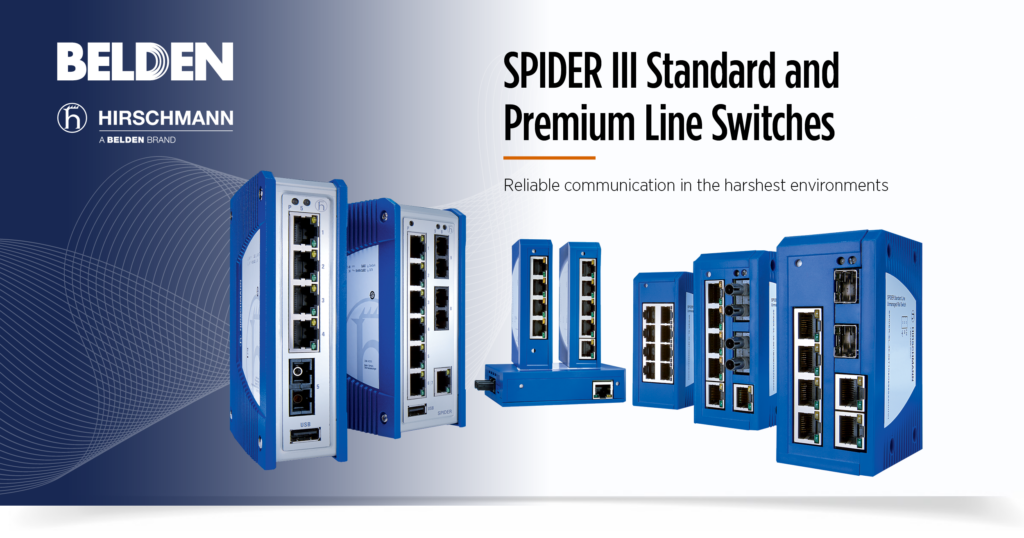

Heard about our SPIDER III Industrial Ethernet switch family?

The SPIDER III entry-level switches provide flexible, cost-effective expansion of twisted-pair and fibre networks. They require no external power supply. The family is available in both standard and premium versions, the specific requirements of your application will determine which you use.

SPIDER III STANDARD LINE: Cost-Effective and Compact

- Designed especially for reliable operation in harsh industrial conditions

- Small size saves space in tight areas and makes installation simple and fast

- High data throughput achieved by Gigabit data speeds, while fiber communication options ensure long-term scalability

- Reduces overall lifecycle costs with low power consumption

- Increases performance and reduces costs with PoE+ for greater power to more devices, without an external power supply

SPIDER III PREMIUM LINE: Full-Featured and User Customizable

The Premium Line offers similar port densities and media mixes, but meet a broader range of market-specific certifications, standards and approvals. Approvals include those for use in process industries (ISA12.12.01 and ATEX Class 2), transportation applications (EN 50121-4 and E1) and marine applications (Navy GL and DNV). In addition the switches fulfill PROFINET Conformance Class A requirements to set up PROFINET networks.