Providing power for transportation applications presents several technical challenges. Batteries have long been the power source of choice for engine start-up. Although conventional lead-acid batteries were the only type available, recent innovations comprising different chemical combinations and construction methods have significantly improved power density and reduced their weight.

Modern public transit trams and trains have further increased the power delivery requirements due to the increasing variety of onboard information and Wi-Fi connectivity systems. As many rail vehicles are turning to an all-electric drive train, the needs expand further. The operating environment also presents many challenges, involving engines or motors starting in low-temperature conditions, a challenge for most battery technologies.

This article investigates how ultracapacitors present a viable and complementary source of energy for transportation applications.

Diversity of mass transportation systems

Our society is increasingly aware of energy usage and how we get from A to B. New metropolitan light rail, bus, and mass transit networks as well as existing railway infrastructure are experiencing significant investment as consumers look for an alternative to congested roads.

Most major conurbations have either implemented or have planned new public transportation systems that help ease city congestion and reduce pollution.

Designing energy-efficient, sleek, and nippy public transportation vehicles dictate balancing the traction and energy storage components’ overall weight and load-carrying capacity.

Power delivery challenges

Batteries provide an ideal source of energy mobility; however, for modern, demanding transportation applications, they don’t always fulfil all requirements. Accommodating high peak current loads requires more batteries than normal running load conditions, adding more weight and increasing the charging time. Banks of batteries are bulky and need considerable charging time, impacting operational availability. Also, batteries are constrained by ambient temperatures, particularly with extremes of low and high temperatures.

Some battery technologies also slowly discharge in-situ due to their internal equivalent series resistance (ESR). ESR is also a factor that limits the maximum amount of current they can deliver and results in heating within the battery.

Another aspect of batteries is their life cycle. During their active life, they also require checking and routine maintenance. They typically have a finite in-service life, after which their capability to store a full charge and deliver a full load becomes significantly reduced.

One further consideration when working with batteries is their restriction at low temperature applications. They lose their capacity as temperature decreases and cannot be used in extreme cold conditions.

For an electrically powered bus or tram, the battery capacity determines the operating range. That range can be extended by regenerative braking concepts by harvesting energy from the drive motors when the vehicle is decelerating. A substantial amount of energy is generated, albeit over a relatively short period. To take full advantage of this method of energy generation requires a method of quickly storing it.

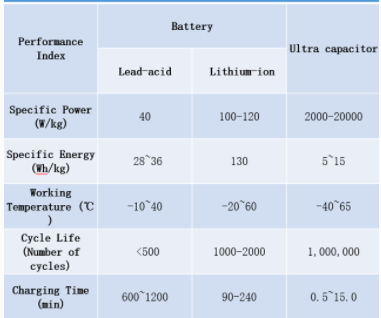

Figure 1 highlights the performance of characteristics of lead-acid and lithium-ion batteries compared to an ultracapacitor.

Recent innovations in capacitor technology have led to the design of relatively compact capacitors with high capacitance values, termed supercapacitors and ultracapacitors. These capacitors offer exceptional energy-to-weight characteristics – see Figure 1 – and are becoming an emerging option for transportation energy storage applications. With their high-power density, rapid charging and high discharge current attributes, ultracapacitors satisfy the demand for engine start-up, a peak load capability, and regenerative energy storage.

Ultracapacitors and their suitability for transportation systems

Supercapacitors and ultracapacitors are high-capacity capacitors with capacitance values in the tens and hundreds of Farads. An ultracapacitor capacitance range typically extends further into thousands of Farads. They behave like any ordinary electrolytic capacitor, such as the ability to charge and discharge rapidly. However, their low internal resistance and energy storage capability make them more similar to a rechargeable battery. Because of this, ultracapacitors are fast becoming a viable energy storage medium, potentially replacing conventional batteries in some use cases.

Ultracapacitors from specialist supplier Supreme Power Solutions (SPSCAP) use an activated carbon coating and organic electrolyte.

This approach yields a capacitor with high capacity, low internal resistance, low leakage and high-reliability characteristics. A porous activated carbon electrode’s high surface area and charge separation by a thin electrolyte layer create an electric double-layer capacitor.

Transportation use cases for ultracapacitors include:

- Braking energy recovery systems for subway trains and light rail trams.

- Integration with batteries for high performance.

- Low-temperature start-up of diesel locomotives.

- Load balancing for multiple carriage drive units during fast acceleration.

For engine start-up, ultracapacitors can deliver the instant peak load capability required to start a diesel engine, prolonging battery life and reducing maintenance and replacement costs.

Examples of ultracapacitors from SPSCAP include the SCE and SCP series of low ESR, cylindrical, high duty cycle parts.

The SCE series – see Figure 2 – features capacitances in the range 100 F to 800 F, with options of weldable or threaded terminations on one end. With their compact dimensions, power system designers can combine them in series and parallel configurations to form backup power supplies to deliver instant power.

An example is the SCE0360C0, a 360 F, 2.7 V ultracapacitor that measures 35 mm x 62 mm and has an ESR of max. 3.2 mOhm.

An example of the SCP series – see Figure 3 – is the SCP2000C0, a 2000 F, 2.7 V ultracapacitor. With weldable terminations at either end and a duty cycle of over 1,000,000, it suits energy recovery solutions, locomotive engine start, and hybrid drive trains. The SCP2000 measures 60.8 mm x 108.4 mm and weighs 402 g. It can operate across the temperature range from -40 °C to + 65 °C. The maximum peak current is over 2000 A, and the maximum continuous current capability at ∆40 °C (temperature rise 40°C) is 208 A.

Recent additions to the SPSCAP line up of ultracapacitors include the CDCL and CDCM ultracapacitors. The new products comprise a range of different capacitance values, 2.85 VDC working voltage, and compact dimensions. For example, the CDCL family consists of five ultracapacitors with 650 F, 1200 F, 1500 F and 3000 F values.

For popular applications, such as low temperature engine start, a ready-assembled ultracapacitor module provides a quick and easy method of implementation. An example is the MDLC0300C0, a 300F 24 V constructed in a robust IP65 battery-style profile. This unit can operate down to -40 degrees C and can deliver a maximum peak start-up power of 45 kW.

Ultracapacitors; delivering compact high-density energy storage choices for transportation

As the future of our mobility and transportation system ecosystem becomes more diverse, the need for long life, rapid charging, high energy density storage has never been greater.

Ultracapacitors have rapidly become a viable energy storage method for instant power delivery for traction control, energy recovery, and engine start applications. They can complement existing battery installations for peak load and multiple load balancing use cases or become the primary power source for a host of onboard systems.