In the future, data will be analysed by artificial intelligence (AI) with unparalleled skill, the entire nature of reality will be evaluated and measured at the quantum level, and machines will not only seamlessly connect with one another but also be able to recognise their own mistakes. The futuristic devices created to advance our knowledge and mastery of the technological universe are known as the Tools of Tomorrow, and this is their fundamental concept.

In this article, we are exploring the innovating pathways, illuminating the cutting-edge technologies that are positioned to transform the Test and Measurement industry. These innovations represent more than simply tools; they open doors to an era in which precision and insight coexist, bringing in a new phase in how we experiment with, judge, and ultimately improve the world.

Why is Test & Measurement Important?

The term “test and measurement” (T&M) refers to a collection of procedures, methods, and equipment used to assess, analyse, and quantify the properties, effectiveness, and dependability of specific parts, systems, or procedures. It involves comparing characteristics including functionality, accuracy, efficiency, durability, safety, and conformance to predetermined norms or requirements. T&M is essential for assuring the calibre, dependability, and efficacy of goods, technologies, and systems across several fields.

Test and measurement covers a broad area and plays a crucial role in the development of most modern technologies, manufacturing and maintenance. It is used in various industries, including electronics, telecommunications, automotive, aerospace and defence, medical and healthcare, manufacturing, and industrial and environmental monitoring.

Technologies Reshaping the Test & Measurement sector

There are many trends and technologies in Test and Measurement that are transforming this sector. Already, AI has revolutionised data analysis and decision-making processes, enabling predictive maintenance and real-time insights. Blockchain technology ensures data integrity and security, crucial in T&M where accuracy and trust are paramount. With the rise of electric vehicles and the ever-expanding Internet of Things (IoT) landscape, T&M is adapting to accommodate specialised testing requirements for these domains.

Additionally, 5G and Telecommunication technologies are bringing a paradigm shift, providing faster and more reliable connectivity, consequently demanding advanced T&M tools to measure and optimise its capabilities.

6 Innovative Tools and Devices in Test & Measurement

The world is changing rapidly and in the coming years, technologies will become more advanced and innovative, among others thanks to the advanced tools which use IoT, 5G or AI. Have a look below at some of the new tools that are already being used in industry.

1. Advanced Sensors and Probes

Advanced sensors and probes are essential parts of the test and measurement industry because they allow for precise data capture and analysis across a range of applications. Specialised tools, such as advanced sensors and probes are made to precisely measure certain environmental, biological, chemical, and physical properties. For analysis and interpretation, these sensors and probes transform physical occurrences into quantifiable electrical impulses.

There are many types of sensors and test probes useful in many industries, from aerospace and automotive to healthcare and biotechnology. They are also common in customer electronics, environmental monitoring and research. The most common ones are temperature, air and motion sensors.

Distrelec offers a wide range of digital and analog temperature sensors for diverse applications. Digital sensors precisely measure ambient temperature, providing accurate digital output proportional to the detected temperature. The Wurth Elektronik WSEN-TIDS temperature sensor IC is primarily utilised in the monitoring of power systems, circuit boards, HVAC systems, cold chains, and environmental conditions.

Features:

- High accuracy.

- Fully calibrated 16-bit temperature output.

- Selectable output data rate up to 200 Hz.

- Programmable temperature threshold and interrupt.

- Silicon-based digital temperature sensor.

2. Wireless Testing Tools

Wireless testing equipment is essential for providing the dependability, effectiveness, and security of wireless networks. For example network testing instruments or network analysers are used to monitor and test the performance of a network to ensure that it is operating at optimal levels.

The network testers from Fluke’s LinkIQ series are test tools for determining cable performance up to 10 Gb/s and resolving network connectivity issues. In addition to providing distance to fault information and a wire map of the cable under examination, LinkIQ uses frequency-based measurements to verify cable performance. In addition, the LinkIQ runs nearest switch diagnostics to locate critical network problems and confirm switch settings, obviating the requirement for a separate device.

Other features:

- Analogue and Digital Toning.

- Port Blink.

- 802.1x authentication.

- Remote Office Locators.

- Capability to manage results using a LinkWareTM PC.

In Distrelec’s offering you will find more wireless testing analysers, like spectrum analysers, signal generators and other testing tools. Read more on how to test the current here.

3. Benchtop Power Supplies and Power Quality

In the field of T&M, benchtop power supplies are crucial equipment used to power devices and circuits during testing and development. In order to provide consistent and dependable power for exact measurements and testing of electronic parts and systems, they enable satisfactory control over voltage, current, and power output. DC power supplies are especially rising over AC.

With more than 180 new types, the 10000 series from EA Elektro-Automatik offers a wider range of power from 0 to 600 W and 0 to 30 kW. The new versions provide expanded voltages from 0 to 10 V, 0 to 2000 V, and output current as high as 1000 A—a major improvement over the preceding 9000-series power instruments. Find out more about the EA Elektro-Automatik’s 10000 series expanded portfolio here.

In terms of power quality, it refers to evaluating and preserving steady electrical power during testing. Harmonics and voltage fluctuations are detected using monitoring tools like power quality analyzers. Power quality analyzers are used for measuring and evaluating the quality of electrical power. They are also utilised in renewable energy storage by ensuring consistent and reliable power supply from the energy storage system.

The power quality analyzer from Chauvin Arnoux is a tool designed for inspection and maintenance teams in commercial or industrial buildings. It may give a quick overview of the key aspects of the electrical network quality. It is lightweight, accurate, and provides a variety of processing options in addition to a huge number of determined values.

4. Robotic Testing Systems

Robotic testing equipment is an innovative and evolving aspect of T&M that involves the integration of robotics into the testing process. Robots like industrial robot arms or cobots are designed to automate and streamline testing procedures, providing a range of benefits to the field of T&M. By incorporating robotics into the testing process, companies can improve test quality, reduce costs and time, and improve worker safety.

5. Automated Test Equipment

Automated Test Equipment (ATE) improves testing processes for electronic components, enhancing accuracy and efficiency. It’s commonly used in electronics manufacturing, telecommunications, medical, and aerospace industries.

Key Components of ATE:

- Test Instruments – ATE consists of various test instruments such as oscilloscopes, multimeters, signal generators, and spectrum analysers that are utilised to measure and analyse electrical parameters.

- Control Hardware and Software – ATE systems are controlled through specialised hardware and software that define the testing procedures, automate test sequences, and collect and analyse data.

- Fixturing and Probes – Customised fixturing and probes are used to connect the electronic device under test (DUT) to the ATE system, ensuring proper electrical connections for testing.

ATE ensures precise testing for various components, from PCBs (In-Circuit Testing – ICT) to vehicle parts (motors, engines, sensors). It also encompasses semiconductor testers for IC evaluation and RF testers for radio frequency system assessment. This adaptability extends to memory devices, consumer electronics, and medical equipment, showcasing its significance in the field of Test & Measurement.

Distrelec distributes the SUCOFLEX 500, RF cable assembly from Huber+Suhner which guarantees the highest level of T&M tool satisfaction. The brand provides the finest phase and amplitude stability against flexure, movement, temperature, and tensile stress, in addition to superior return and insertion loss up to 70 GHz, thanks to their distinctive cable and connector design. SUCOFLEX 500 assemblies typically sustain more than 100,000 flexures without performance degradation because of the rotary swaged low-loss inner conductor and the robust design, giving them a very long lifespan.

6. Software-defined Test

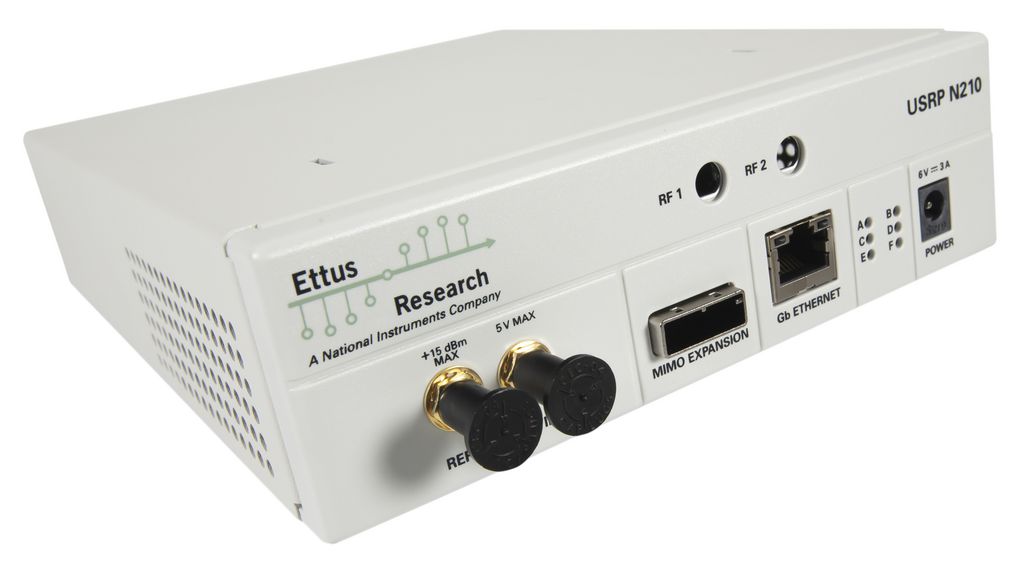

A new paradigm in the field of test and measurement called software-defined test (SDT) focuses on using software-based methods to manage, automate, and regulate various testing procedures. Many hardware and software are used in the world of SDT to provide software-based testing, automation, and control. A versatile, software-driven testing environment cannot be created without these devices. An example can be a software-defined radio that allows for the flexible configuration and reconfiguration of radio hardware and protocols through software. It’s extensively used in wireless communication testing, enabling the emulation of diverse communication standards and frequencies.

The USRP N210 High-Dynamic Software Defined Radio from Digilent enables engineers to quickly create and implement strong, adaptable software radio systems and is the highest performance class of hardware in the USRP™ (Universal Software Radio Peripheral) family of products. For applications demanding excellent RF performance and large bandwidth, the N200 and N210 hardware is the best choice. These include networked sensor deployment, dynamic spectrum access, cognitive radio, record and playback, physical layer prototyping, and spectrum monitoring.

Conclusion

The course of test and measurement is changing as a result of the convergence of cutting-edge technology. AI, 5G, software-defined testing, robotics, and sophisticated sensors are advancing accuracy, adaptability, and efficiency. Results like quicker development, better user interactions, and dynamic testing environments are anticipated. But solving security and integration issues is essential to realising their full potential. These new techniques will revolutionise how emerging innovations are evaluated, tested, and ensured, illuminating the direction we should take.