As we become more experienced with Industry 4.0 technologies and head towards Industry 5.0, more and more factories are building a future where humans and machines work in harmony, by adopting procedures which incorporate automation, AI (Artificial Intelligence) and IIOT (Industrial Internet of Things). When smart factories adopt these three technologies for their everyday processes it improves profitability and productivity whilst also reducing wasted time and energy.

The key component which allows machines to work automatically is called a programmable logic controller (PLC). The PLC is commonly used in factories to automate a variety of sequential and repetitive processes, playing an important role in Industrial IOT. The controller uses all three of the previously mentioned technologies to fulfil its purpose.

A report from Statista projects that the global PLC market will be worth over 15 billion US dollars by 2026, whilst Grand View Research states that the global market size of industrial automation stood at 158 billion US dollars in 2021, and is expected to achieve a compound annual growth rate (CAGR) of 10.2% between the years of 2022-2030. Needless to say, PLCs will play a huge role in industrial automation’s substantial projected growth over the next decade.

What is a PLC?

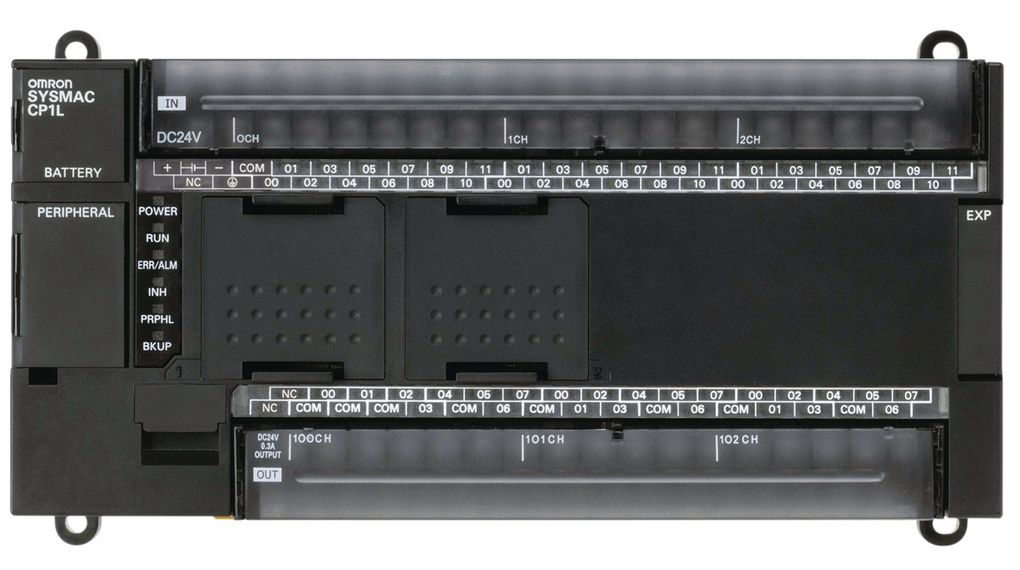

Put simply, a PLC is a small, modular computer which has been programmed to control certain tasks and processes in factories across a range of industries. The PLC is made of solid state and consists of a central processing unit (CPU), and input and output modules, often referred to as I/O.

How does a PLC work?

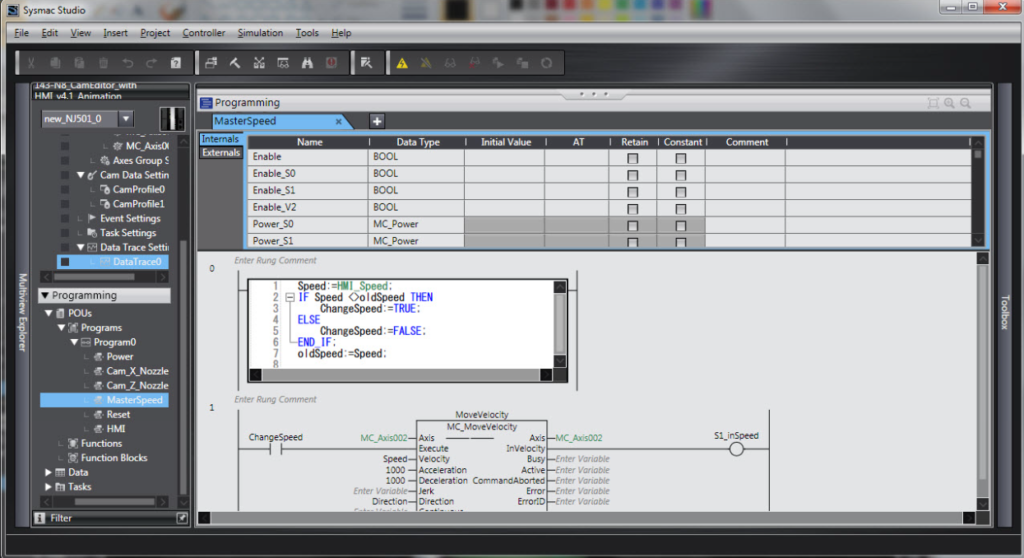

In addition to the modules that comprise the controller, a PLC also needs to be connected to a programming device and a power supply. A programming device is usually a laptop or computer that will have programming software downloaded. This software is used to create instructions or ‘logic’ for the PLC, based on different outcomes reported by the inputs. As well as a range of PLCs, the Distrelec webshop also stocks Omron’s programmable software Sysmac Studio.

After it has been programmed, the PLC can then carry out the instructions that have been programmed to it, and communicate next steps to the outputs or to the operator if it has detected an issue. The CPU section of the controller also has memory, so the instructions can be stored onto it.

The PLC continuously monitors input field devices and can make decisions based on the custom programmable instructions created by the user to control output devices.

Types of input devices

- Sensors

- Switches

- Buttons

Types of output devices

- Relays

- Lamps

- Valves

The four steps of a PLC

Take a look below at the four steps that the PLC takes on a continuous loop to ensure effectiveness.

- Input scan – First, the PLC scans all input devices that are linked to it to determine their current states.

- Program scan – After the input devices are scanned, it must refer to the user created logic.

- Output scan – Following the custom program, the PLC operates all output devices.

- Housekeeping – Performs any internal diagnostics and communicates with the programming device.

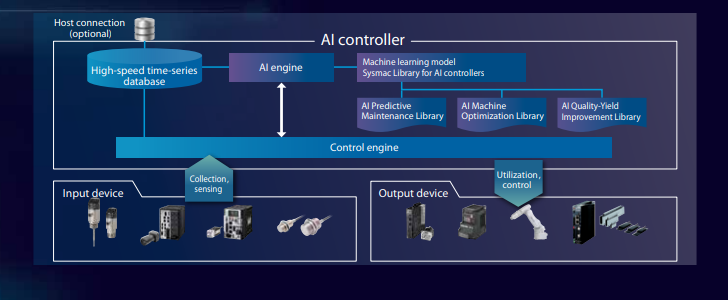

Machine learning and predictive maintenance with PLCs

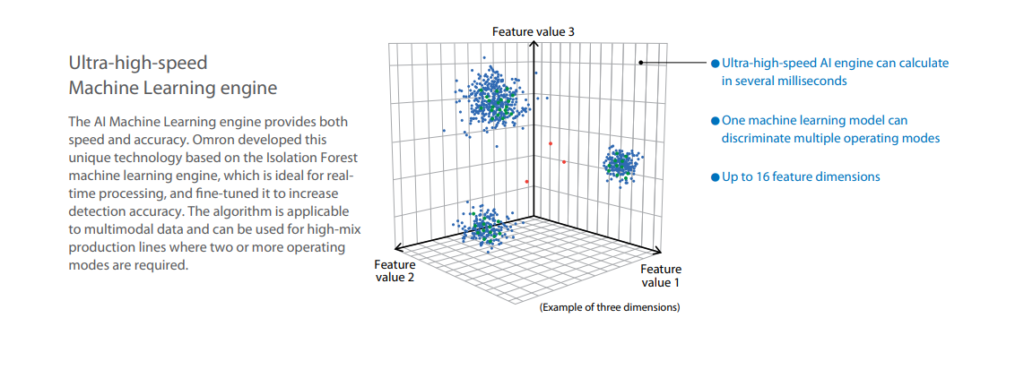

PLCs are integrated with state-of-the-art machine learning capabilities, meaning operators can collect valuable, real-time data which can help to increase equipment life-cycles and product quality. The controllers are able to inform the user of any problems by anomaly detection. Due to its intensive machine learning ability, it’s easy for the controller to detect if anything differs from the usual operation of the machine.

The controller learns the data patterns of nominal machine behaviour, without being explicitly programmed, meaning anomalies can be detected and acted upon quickly. This process allows for each machine to move from reactive or scheduled maintenance to status-based maintenance, meaning maintenance will only be performed when truly necessary, keeping costs down to a minimum and almost eliminating any machine downtime.

Benefits of status-based maintenance

- Minimised downtime means that production losses are reduced.

- Replacing components only when necessary reduces stock of components.

- This form of maintenance lowers reactive maintenance costs.

- Indicators can identify the location of machine errors.

- Maintenance work can be standardised and skilled engineers can bring new value.

Distrelec’s webshop stocks a range of AI automation controllers including Omron’s NX and CP series. Omron’s PLCs can be used in a range of industries and are an essential piece of kit for determining when predictive maintenance needs to be carried out too. With Omron’s AI-based PLCs, anomalies can be detected in mere milliseconds, enabling the highest speed and security of data processing. Find out more below about how Omron’s PLCs work to ensure operators can perform predictive maintenance before an error occurs.

Predictive maintenance

The predictive maintenance procedure of Omron’s AI PLCs includes five main steps:

- Generating a learning model – Nominal machine behaviour is learned and real-time machine data is used to generate a learning model and threshold value.

- Monitoring the machine – The machine is continuously monitored based on the generated learning model. If the specific features exceed the threshold value, a notification is issued to the operator.

- Setting a new threshold value – The machine status is checked and if no issue is detected, a new threshold value is set.

- Maintenance performed – Programmatically determine what maintenance is required, including component replacement.

- Generating a learning model with new components – A new learning model and threshold value is generated based on the previous error level after components are replaced. Repeating these steps makes status-based maintenance more reliable.

Recommended products