Omar Qayyum Product Manger at Alpha Wire

Omar has been a Product Manager with Alpha Wire since 2019. With a background in engineering, Omar’s focus in his role at Alpha Wire is supporting the company’s innovation and R&D initiatives in order to meet the ever-evolving challenges of the markets served by the company.

1.Who are Alpha Wire and what do they produce?

For over 100 years, Alpha Wire has developed wire, cable and wire management solutions designed to offer superior performance and reliability across demanding markets, including industrial automation, semiconductor fabrication, medical devices, and more. Founded in 1922, the company has manufacturing locationswi in Carson, California, and Leominster, Massachusetts, along with five sales offices across the globe.

2. What applications and solutions are Alpha Wire products suitable for?

- Industrial Automation – Manufacturing Automation, Order Fulfillment Centers/ Warehousing, Material Handling, Food and Beverage, Mining

- Medical – Imaging, Diagnostic, Instrumentation

- Semiconductor – Deposition, Etching, Wafer-Handling, Inspection and Testing

- Aerospace & Defense – Vehicles, Tactical Communication, Target Acquisition and Tracking

- Consumer Electronics – Lighting (LED, Architectural), Mobile Vehicles, Home Appliances

- Energy – Alternative Energy, Green Energy, Conventional Generation, Transmission and Distribution, Oil and Gas

3. What advice would you give to aspiring engineers and those wanting to work in your industry?

Stay on top of innovation. The market is continuously changing, and innovation is a key to remaining relevant. Additionally, focus on continuous improvement. Learn from the performance of the products you have in the market, and use that feedback to continue to innovate.

4. What are some of the challenges of developing and deploying applications in these sorts of environments?

Some of the challenges faced by our customers include complex installation, continuous motion applications that require high-flex cable, and a limited design envelope. Due to the markets we serve, there is also often risk of exposure to oil, abrasion, sunlight/UV, and flame. Additionally, our customers often have specific requirements around the environmental impact of their operations, including requirements for Low Smoke Zero Halogen cable, recyclability, and phthalate-free materials.

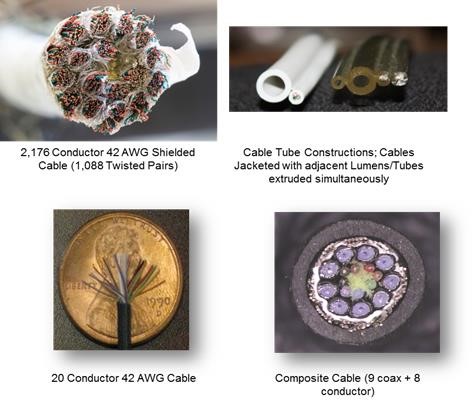

One challenge this presents is that an engineer may not be able to find a cable currently on the market that fits their requirements. At Alpha Wire, we have a robust custom cable design process, in which our engineers will work directly with the customer to develop a solution that matches all of their design requirements, including environmental and regulatory specifications. In addition to our broad custom cable design capabilities, we also have low minimum order quantities for prototypes.

5. What new products and technologies is Alpha Wire working with/on? What are the key areas of innovation with those products?

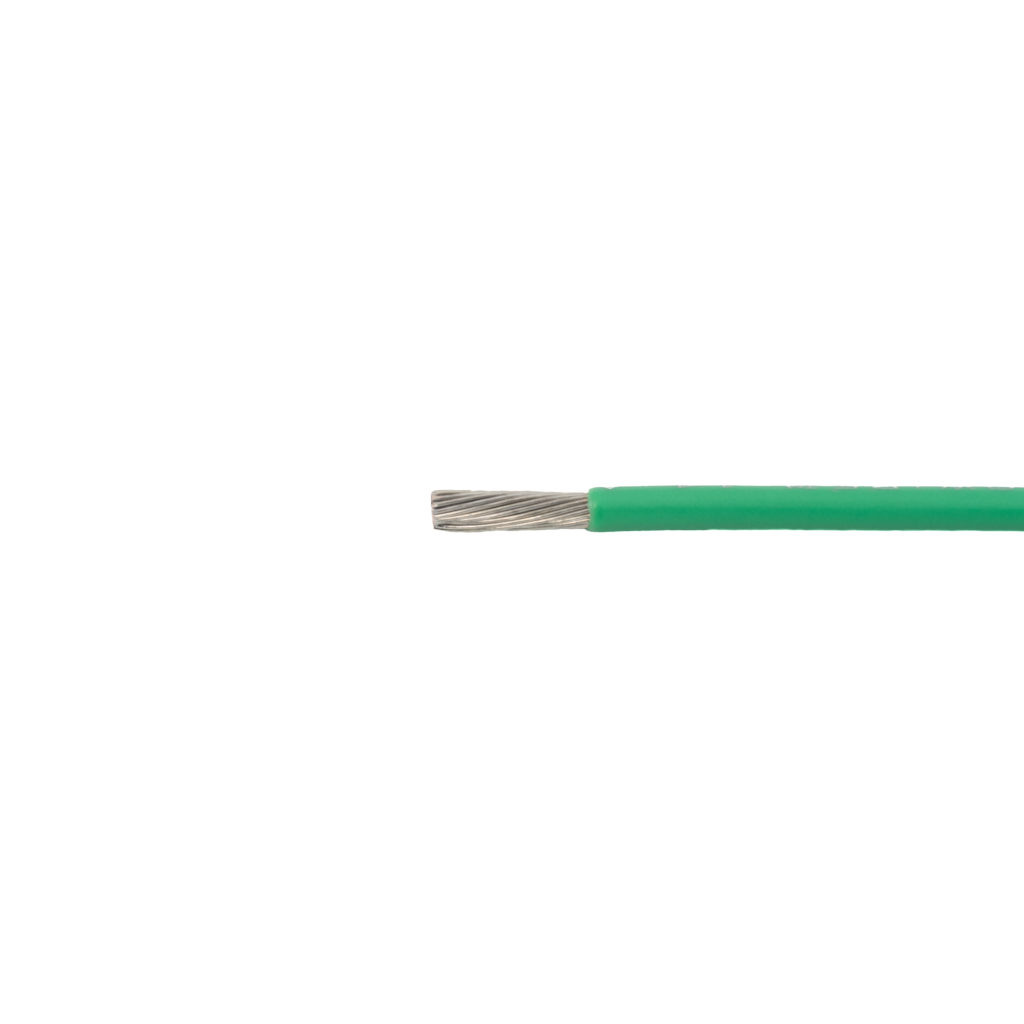

We recently relaunched our ThermoThin range of hook-up wire, which features an exceptionally small and lightweight construction, and is designed to withstand extreme temperatures. We’re also looking ahead to the upcoming launch of our ThermoThin Multiconductor products, which also withstand high temperatures and feature a PTFE-alternative material.

Our Metric EcoWire® family is up to 45% smaller and 40% lighter than 600V PVC alternatives, and is 100% recyclable.

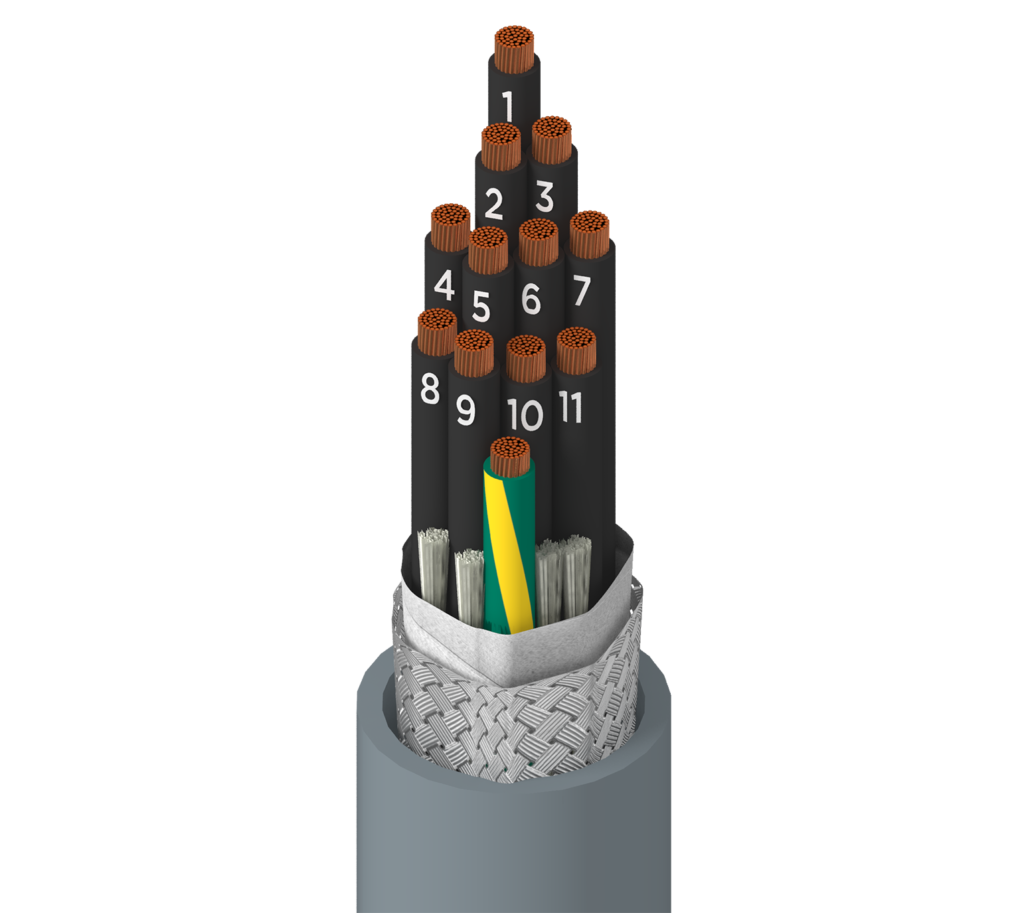

We have also recently introduced extensions to our XtraGuard product family. Those include XtraGuard Flex TPE cables, which are rated for 1 million flex cycles, and our Xtra-Guard® Industrial Ethernet flex cables, which are rated for a minimum of 10 million continuous flex cycles and 3 million torsional flex cycles.

We now also provide non-magnetic coaxial cable options, which provide better signal transmission with minimal distortion while handling higher frequencies.

And we are preparing for the release of our MultiFlex Mini line, which supports robotics and collaborative robot OEMs who are challenged with both space/weight constraints and complex continuous flex motion in harsh environments.

6. What is Alpha Wire excited about in 2022?

This year, we’re proud to celebrate our 100th anniversary. Alpha Wire was founded in 1922 as a supplier of wire strengtheners to the military industry. In the century since, the company has innovated to supply high-performance wire and cable products to a range of industries, from the early days of radio and television, to defense electronics during World War II, and on to our present-day solutions for various demanding applications. We’re proud to celebrate 100 years of excellence in product expertise and customer service.

7. Why should our customers invest in your products and what sets your products apart from the competition?

What sets Alpha Wire apart is our ability to meet the needs of application-driven, high-end capital equipment device manufacturers and automation solution providers. We have a broad product offering, with more than 24,000 standard part numbers. We offer low minimum order quantities on most of our standard portfolio. And we also have a strong R&D team with engineers working collaboratively with customers to design custom cable solutions that meet their application’s requirements.