Hydropower, often known as hydroelectric power, is a type of renewable energy that generates electricity by harnessing the natural flow of flowing water. In the current world situation and plans to achieve net zero by 2050 (some countries even earlier), it is one of the key energy sources enabling the green transition.

To make the transition quicker, it is important to buy products from proven brands, such as Jumo – a leading global supplier of sensor and automation components and systems. All economic activity at JUMO is guided by the notion of sustainability. Since the beginning they have focused on manufacturing organically and without acquisitions. Their product range has been increasing and now they offer sensors, transmitters and conductivity measurement devices that allow for hydrogen applications.

If you are curious how these devices can improve your manufacturing and create a sustainable working environment, read on.

Benefits of hydropower technology

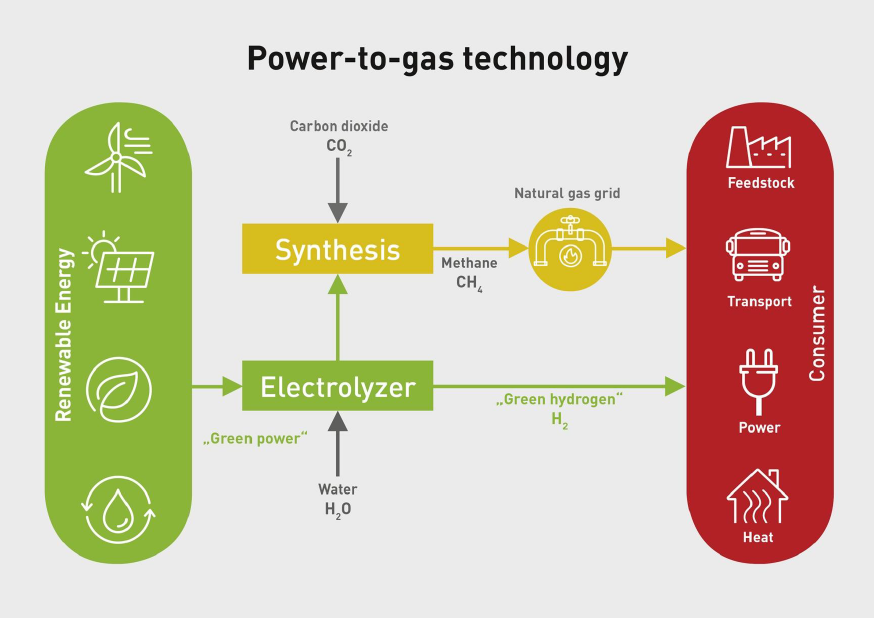

To achieve net zero, companies will need to pursue deep decarbonization which means deployment of CCUS (Carbon Capture, Utilisation and Storage) and low-carbon hydrogen. Below we present the advantages and applications of hydropower.

Hydropower:

- is an energy carrier;

- is a substitute of coal and natural gas;

- may be stored long term and at large capacity;

- is supporting 4 key technologies, such as:

- Electrolysis – an electrolyzer produces hydrogen from green power

- Energy conversion from hydrogen for heat and transport based on cell technology

- Transport and storage – e.g. pipelines, filling stations

- Synthesis – production of methane and e-fuels

Read more about how hydropower plants enable the green energy transition here.

JUMO Hydrogen applications

Despite the fact that hydrogen has been utilized in industrial refining processes for decades, it now has a variety of uses, including the production of green hydrogen by water electrolysis, conversion into synthetic fuels, and use in fuel cell electric vehicles. Jumo offers hydrogen-compatible products that have been proven in the field and evaluated in hydrogen labs.

Pressure transmitters

A pressure transmitter is a mechanical device that monitors a liquid or gaseous sample’s expansion force. This sort of sensor, also known as a pressure transducer, is made up of a pressure sensitive surface area composed of steel, silicon, or other materials, depending on the analyte’s composition.

The JUMO MIDAS SO5 pressure transmitters have both relative and absolute pressure measurement ranges. The instrument is universal and can be used even under extreme situations, thanks to its high-quality stainless steel welded measurement system with no seals. Its design provides the highest level of protection against the process medium escapin, it is equipped with a silicon sensor that can withstand tremendous overload, even in the smallest measurement ranges, and can withstand millions of pressure cycles.

The pressure transmitters can be used:

- in cooling and air conditioning systems

- compressors

- mechanical engineering

- commercial vehicles

- industrial pneumatic uses

The Pressure Transmitters with Switching Output Delos SI allow for measurement of liquid and gaseous substances and allow measuring control via software.

Temperature sensors

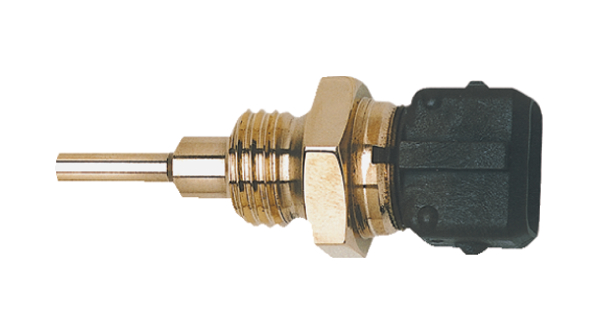

Temperature sensors – besides their general applications, such as records, monitors and signals temperature changes – address the need for precise temperature monitoring in fuel cells and other hydrogen-powered or hydrogen-using technologies for processing and safety.

JUMO VIBROtemp temperature sensors are used to monitor the temperature in fuel cells. Thus by using screw-in RTD temperature probes the temperature measurement is possible in utility vehicles, construction and agricultural machinery, motors, compressors, and railway technology.

Conductivity measurement

The high thermal conductivity of hydrogen can be used to assess hydrogen content in gases. To determine electrolytic conductivity in liquids, JUMO conductivity sensors are used in conjunction with appropriate transducers. The JUMO sensors operate on a two-electrode basis. They get alternating voltage from the transducer. The conductivity of the medium determines the amount of current that flows through the liquid and electrodes.

Possible applications include:

- Chemicals

- Food technology

- Pure and highly-purified water

- Pharmaceutical industry

- Chip manufacturing

- Ion exchangers

- Reverse osmosis plants

For liquid analysis, Jumo is offering the intelligent, bus-capable connection for digital sensors in liquid analysis. The JUMO digiLine offers Plug and Play functionality and enables efficient and quick measurement of several parameters.

Safety monitoring

The major objective of safety temperature limiters is to properly monitor thermal processes and, in the case of a failure, to switch plants to a safe operating condition. The JUMO safetyM STB/STW Ex, which is small and user-configurable, can now detect dangers in Ex-areas that could result in personal injuries, environmental damage, or destruction of the industrial facility and materials.

Automation

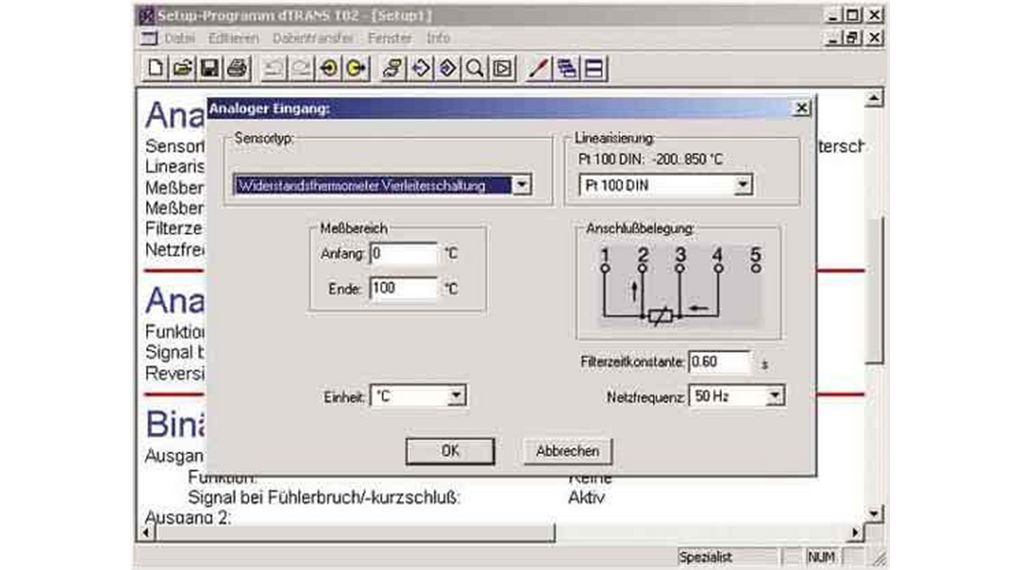

The automation of hydrogen facilities is possible with more innovative solutions, digitalisation and networking in the plant, there is safety and integrated control technology. With programmable controllers from the ecoTRANS series from JUMO, the transition towards more innovative solutions can be simpler.

This product is designed to use in general water technology allowing for measurement of liquids with conductivity measuring cells. To control and monitor, helpful might be the ecoTrans software from Jumo. See the setup program dTRANS, an accessory for ecoTRANS series, below.

Distrelec is a distributor of equipment from Jumo. Through the range of products that Jumo offers, Distrelec is well positioned to support customers in the green energy transition at their facilities. Search more JUMO products here.