The sector of smart manufacturing is about to undergo a transformation thanks to quantum computing, bringing in a new era of productivity, speed, and creativity. Quantum computing has the potential to revolutionise product design, optimisation, and manufacturing since it can handle enormous volumes of data and solve complex problems at an unprecedented scale.

According to McKinsey and Company, although quantum computers won’t replace today’s computers, they will be able to solve extremely difficult statistical issues that current computers are unable to handle.

In this article, we’ll examine how quantum leaps affect smart manufacturing and how they make it possible to produce better things more quickly and affordably.

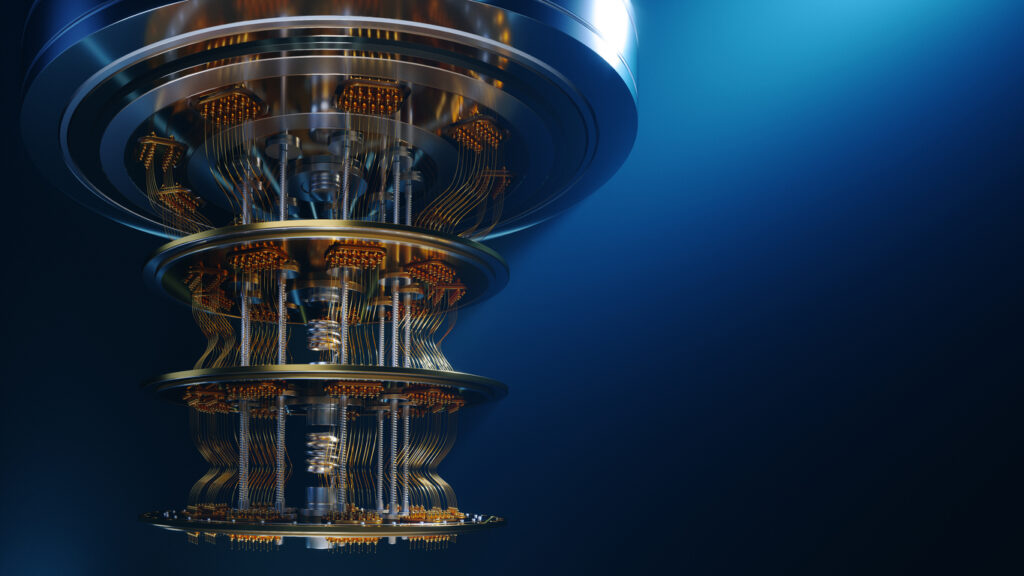

Understanding quantum computing

Quantum computing is a field that combines principles from quantum physics and computer science to develop powerful computational machines. Quantum computers use quantum bits, or qubits, which are capable of existing in a superposition of both 0 and 1, in contrast to classical computers that use bits to represent information as either 0 or 1. This unique property enables quantum computers to process more datasets than classical systems and to do parallel computations.

Quantum power for machine learning and optimisation

Machine learning and optimisation are two of the most important fields where quantum computing is having a huge impact. Quantum machine learning algorithms enable speed-up tasks like pattern recognition, classification, and grouping. These algorithms can more effectively handle high-dimensional data, resulting in increased accuracy and shorter training times.

Traditional optimisation problems like resource allocation, scheduling, and supply chain management can be very difficult to solve with conventional methods. Quantum-inspired optimisation algorithms, which are based on quantum ideas, can be used to resolve these problems more successfully. These algorithms are better able to sift through a huge space of alternative solutions, which improves production processes and more effectively uses resources.

Quantum computing’s role in advancing chemistry and biology

Quantum computing’s potential in smart manufacturing extends to chemical and biological processes. In collaboration with leading quantum computing experts, researchers at many prestigious institutions, like Harvard, are exploring how quantum-inspired algorithms can streamline the development and production of chemicals in the fields of medicine, AI, pharmaceutical development, and others.

By leveraging the computational power of quantum computing, researchers aim to reduce the time and cost required to bring new chemicals to market. These advancements have the potential to revolutionise the chemical industry and pave the way for more sustainable and efficient manufacturing processes.

Quantum-inspired algorithms and intelligent testing

It may be difficult and expensive to scale manufacturing methods from research labs to mass production. Quantum-inspired algorithms enable intelligent testing and optimisation, which eliminates the need for costly trial-and-error experimentation. These algorithms allow researchers to focus their efforts and resources on the regions that need further examination and scale up and commercialise innovative products more effectively, resulting in a shorter time to market and cost savings.

Quantum computing and predictive maintenance

Predictive maintenance is essential for providing optimal equipment operation and reducing downtime in the era of smart manufacturing. By analysing enormous volumes of sensor data and finding patterns that point to possible equipment faults, quantum computing might improve predictive maintenance procedures. Quantum algorithms can help manufacturers create more precise predictive maintenance models, enabling proactive maintenance procedures and minimising unscheduled downtime. Have a look at other trends which are leading in predictive maintenance.

Quantum-safe cryptography and data security

As data collection, processing, and transmission are key components of smart manufacturing, protecting the security and integrity of sensitive data becomes crucial. Quantum computing has the potential to compromise popular encryption protocols like RSA and ECC that rely on the complexity of factoring huge numbers.

Scientists are currently engaged in the development of cryptographic methods that are resistant to quantum computing to mitigate the potential threat. By using quantum-safe encryption techniques, these advances guarantee the long-term security of industrial data. Furthermore, these techniques defend against possible attacks in the post-quantum period, guaranteeing data security in the industrial sector over the long run. Find out more about industrial security here.

The quantum advantage in supply chain optimisation

Effective supply chain management is essential for smart industrial operations. Already, manufacturers are using robotics to improve supply chain management in logistics. However, the technology is advancing, and with quantum computing, it is possible to optimise complex supply chain networks by simultaneously considering many variables, constraints, and optimisation goals. Algorithms inspired by quantum mechanics can be used to find the optimum routes, reduce transportation costs, and optimise inventory levels, increasing supply chain efficiency and a drop in operating costs. By using quantum computing, manufacturers can obtain significant competitive advantages worldwide, and quantum robots may replace traditional AI one day.

Exploring quantum computing’s influence on material innovation

The development of new and advanced materials is a key driver of innovation in smart manufacturing. Quantum computing helps develop new materials, and researchers can learn more about the structure, stability, and functionality of these materials by mimicking the behaviour of atoms and molecules at the quantum level. With the help of this understanding, unique materials can be created that have greater strength, conductivity, and durability. The incorporation of quantum computing into material design presents a compelling opportunity to create premium products across various industries.

Quantum computing and energy optimisation

In the pursuit of sustainable manufacturing, energy optimisation takes precedence. Quantum computing plays a crucial role in analysing complex energy systems and identifying opportunities for energy conservation. By simulating and modelling energy flows at the quantum level, researchers can develop highly precise algorithms for energy optimisation. These algorithms enhance the overall energy efficiency of industrial operations, optimise energy consumption, and reduce waste. They could lead to advancements in a number of fields, such as improved solar cell efficiency or improvements in electric vehicle battery technology.

Quantum computing’s ability to tackle demanding energy management optimisation challenges also enables the creation of greener and more sustainable smart factories. Through its application, quantum computing contributes to the development of a more environmentally conscious manufacturing industry.

Quantum innovation in the future of smart manufacturing

As technology advances, quantum computing’s impact on smart manufacturing will only grow. The ability to examine massive amounts of data, tackle difficult optimisation problems, and accelerate machine learning processes will redraw the boundaries of what is possible in manufacturing. Intelligent manufacturing allows products to be manufactured more rapidly, more cheaply, and with higher quality and performance. Quantum computing will enable new levels of productivity, creativity, and competitiveness, reshaping the industry as we know it in the process.