Secure and trustworthy connections are essential in today’s interconnected world where electrical systems are vital for powering our lives. That’s where cable glands come into the picture.

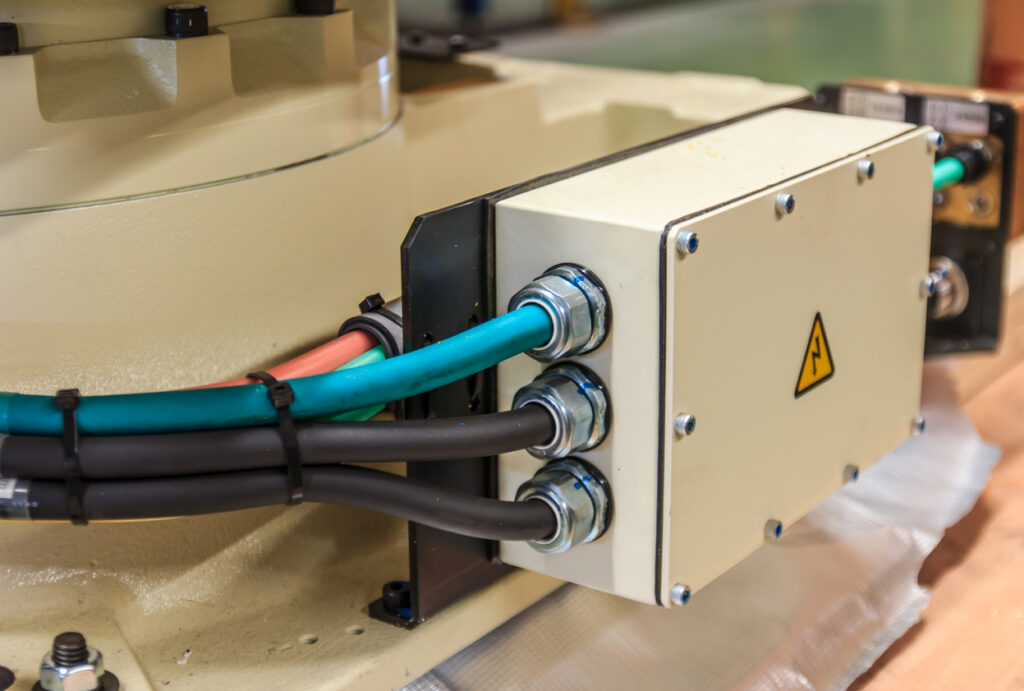

Cable glands or cord grips are important but sometimes disregarded parts that secure and protect cables and create a solid and reliable connection. They are commonly used in industrial applications, mainly to pass cables out of an enclosure in a watertight manner with simultaneous strain relief.

Understanding cable glands and their function is crucial to attaining effective and secure communication, whether you’re putting up a new electrical system or maintaining an old one. This is where RND comes to help, with an in-depth guide to cable glands.

The Functions and Benefits of Cable Glands

Cable glands serve several important functions and offer numerous benefits in electrical and industrial installations.

Here are the key functions and benefits of cable glands:

- Cable securing – fastening and holding cables in place.

- Cable protection – shielding cables from moisture, dust, and chemicals.

- Environmental sealing – creating a tight seal to prevent the ingress of contaminants.

- Strain relief – alleviating tension and stress on cables.

- Electrical continuity – maintaining grounding and shielding integrity.

Benefits:

- Safety – minimising the risk of electrical hazards.

- Reliability – ensuring stable and dependable connections.

- Versatility – available in various sizes and designs for different applications.

- Easy installation and maintenance – user-friendly designs for quick and efficient installation.

- Compliance with standards – meeting industry safety and performance requirements.

Cable Glands Types

There are several types of cable glands in electrical installations. We have highlighted some of the main types:

Single compression

Typically employed in buildings and smaller installations, these cable glands have a single sealing mechanism. Depending on the sealing requirements and climatic circumstances, they are available in several types and provide a secure connection for cables.

Double compression

Dual sealing mechanisms are used in double compression cable glands to provide stronger seals and improved protection. They are frequently used in factories, power plants, and other applications that call for greater reliability and resilience.

Additionally, single and double-compression cable glands are available in different types:

- Waterproof – designed to provide a seal protecting from water. They are used in applications where cables may be exposed to moisture or submerged in water. They often have IP68 ratings, indicating a high level of resistance to water and dust.

- Light-duty – made for general-purpose applications with lenient sealing standards is known as a “light-duty” cable gland. When wires need to be safely connected and protected, these glands are frequently employed in interior settings or low-risk areas.

- Flameproof or explosion-proof – made to stop explosions from spreading in risky locations as they have specialised building and sealing methods to keep any sparks or flames inside the enclosure, reducing the possibility of electrical equipment explosions.

Armoured cable glands

Armoured cable glands are designed for a specific use with steel-wire armoured (SWA) cables. These cables contain a steel wire or tape protective coating, and armoured cable glands offer a reliable connection and shield the line from harm.

Unarmoured cable glands

Unarmoured cable glands are more basic than their armoured equivalent and are designed for use with cables that do not have an additional layer of armoured protection, such as steel wires or tape. These glands are specifically intended for cables that do not require the added reinforcement provided by armoured cable glands.

EMC cable glands

EMC (Electromagnetic Compatibility) cable glands are used in applications where electromagnetic interference (EMI) needs to be controlled. They provide shielding against electromagnetic radiation and ensure the integrity of sensitive electronic systems by minimising the impact of EMI.

Heat-resistant cable glands

Specifically designed to withstand high temperatures. They are used in applications where cables are exposed to elevated heat levels, such as industrial processes or high-temperature environments.

Installation and Usage

Before you can begin to install a cable gland you need to choose the right type. Consider the material, IP rating, thread type and temperature range. Always make sure that you choose the right equipment for your application and you follow the manufacturer’s instructions.

To provide a safe and dependable connection, installing cable glands includes many steps. Here is the process of installing cable glands:

1. Choose the right cable gland

Choose a cable gland that matches the cable diameter and is suitable for the specific application and environmental conditions. Then, remove any protective caps or inserts from the cable gland.

2. Prepare the cable

Strip the outer sheathing of the cable to expose the conductors. The length of the stripped portion should be sufficient to accommodate the cable gland and provide proper engagement.

3. Insert the cable into the cable gland

Insert the stripped end of the cable through the cable gland’s entry thread or opening. Then, ensure that the cable is fully inserted, allowing the conductors to extend beyond the sealing area.

4. Position the sealing elements

Arrange the sealing elements, such as rubber or plastic seals, around the cable in the cable gland. These seals provide the necessary moisture and dust protection.

5. Tighten the locknut

Thread the lock nut onto the cable gland’s body and tighten it securely by hand. Avoid over-tightening, as it can damage the cable or the gland.

6. Final tightening

Use appropriate tools, such as wrenches or spanners, to further tighten the locknut and ensure a proper seal. Follow the manufacturer’s instructions regarding torque specifications.

7. Check for proper installation

First, verify that the cable is securely held within the cable gland without any excessive strain or tension. Then, ensure that the sealing elements are compressed evenly around the cable, providing a tight seal. Lastly, inspect for any visible gaps or misalignment that may compromise the effectiveness of the seal.

8. Test the connection

Conduct appropriate tests to ensure that the cable gland and connection meet the desired electrical and safety standards. This may include insulation resistance testing or continuity checks.

Industry standards and regulations

Since safety is a top priority when designing cable glands, each one has an IP rating so you know exactly what you are receiving. The efficiency of the glands and how well they perform throughout various duties is determined by their Ingress Protection Marking (IP). These ratings frequently reach IP68 and IP69K levels. It is crucial to ensure that any devices used in explosive environments adhere to local, national, and international norms of conduct.

Cable glands components & accessories

Cable glands come in various sizes and designs, requiring different tools to match their corresponding locknut dimensions. RND, besides cable glands, offers some accessories and components that can help you install cable glands in the most efficient way.

RND cable glands

Cable glands, available from RND are frequently employed to seal, secure, protect, and occasionally to provide earth continuity to the cables. In addition to nickel-plated brass, nylon, and stainless-steel versions, RND offers a wide range of cable glands in different shapes and sizes, e.g. spiral. Click on the button below to discover the full range of RND cable glands.

Other recommended products

Adaptors

In RND’s selection you can find reduction and expansion adapters made from nickel-plated brass or polyamide in different sizes and shapes to suit your needs. These adapters are specialised components used in cable gland installations to accommodate cables or conduits of different sizes. RND adapters help to bridge the gap between the cable gland and the cable or conduit being connected, ensuring a secure and reliable connection.

Waterproof pressure compensating elements

Waterproof pressure compensating elements, also known as pressure equalisation glands or venting glands, are specialised components used in certain cable gland installations. These elements play a crucial role in maintaining pressure equilibrium inside the enclosure or housing where the cable gland is installed. RND offers pressure compensating elements with IP68 and IP66 protection. They are ideal for use with outdoor lighting, sensor equipment, and outdoor communication equipment.

Spanner tools for cable glands

Spanner tools, also known as wrenches, are commonly used in the installation and maintenance of cable glands. RND offers highly durable spanners made from chrome-vanadium steel designed for tightening and loosening bolts and nuts. They have a long service life and are simple to store and handle.