Sustainability today is not just a better approach; it is becoming a way of living. As a result, individuals and businesses are looking for ways to reduce their environmental impact. One company leading the way to sustainable manufacturing is WAGO, a top international automation and electrical engineering product supplier. In this article, we will explore WAGO’s latest offering, the 221 Green Series of Splicing Connectors, and how it is revolutionising the industry with its commitment to sustainability.

Why is sustainable manufacturing important?

Before we delve into the specifics of the WAGO Green Range, let’s take a moment to understand why sustainability is crucial in the manufacturing industry. Conventional manufacturing techniques mainly rely on fossil fuels like natural gas and petroleum, which not only deplete our limited supply but also harm the environment and cause climate change. Recognising the need for change, WAGO embarked on a mission to develop more sustainable products. Consequently, they created a series of innovative Green products that contribute to the circular economy and reduce fossil fuel consumption.

WAGO 221 Green Range

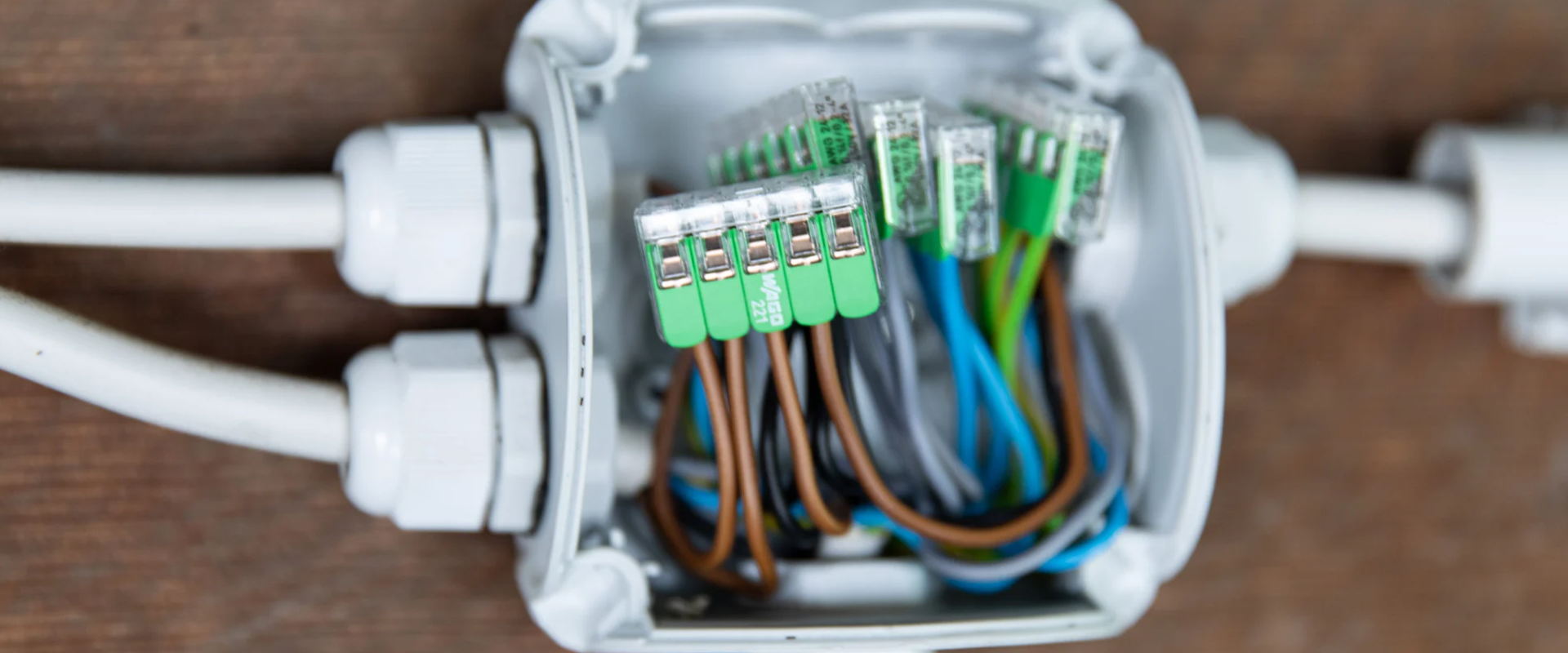

As a brand committed to sustainability, WAGO reimagined one of its best-known products, the 221 Series Splicing Connector. The brand created a variant made to the connector that is made of partially bio-circular and recycled plastics. By using materials that are derived from post-consumer recycled sources and bio-based residues, WAGO aims to reduce the consumption of fossil resources and keep existing resources in circulation.

Key benefits of the WAGO 221 Green series

The sustainably improved 221 green splicing connector has several benefits that make it an attractive choice for those seeking more sustainable options:

- Plastics made from post-consumer recycled material and bio-based residues – The connector is made partially from bio-based residues from household and industrial use, as well as recycled PET bottles.

- Reduced consumption of fossil resources – Utilising recycled and bio-based materials, the WAGO Green Range significantly reduces the amount of fossil fuels, such as natural gas and petroleum, that are typically utilised in plastics manufacturing.

- Same quality and certifications as the original 221 Series Splicing Connector – The WAGO Green Range maintains the same certifications and quality as the original connector even though it uses more environmentally friendly materials. It delivers the same dependable performance and is appropriate for the same applications.

The connectors are made to adhere to the same certification requirements and technical specifications as the original 221 Series Splicing Connector. Both their reliability level and the applications for which they are suitable are the same. Customers can adopt more environmentally friendly practices, knowing that performance won’t be compromised.

Features:

- For all conductor types

- Cross-section max. 4 mm² and min. 0.2mm²

- 2, 3 and 5-conductor versions available

- Transparent housing

- Surrounding air temperature: max 85°C (T85)

- Rated voltage: 450V

- Rated current: 32A

WAGO’s way to greater sustainability

WAGO started its journey towards sustainability by recognising the environmental impact of its manufacturing resources, including energy and plastics. The brand improved its 221 Series Splicing Connector with the goal of lowering dependency on new polymers.

Even before the company launched its improved 221 series, it used regranulate (a type of plastic made from recycled materials) in the manufacturing process to reduce waste and included recycled materials in its products.

However, it wasn’t until the WAGO 221 Green Series that the brand made significant progress towards sustainability. With two-thirds of its plastic coming from sustainable sources, this new connector is made up of at least 27% recycled PBT (lever) and 77% bio-circular PC (housing). The environment will benefit from this change as soon as it is installed.

Bio-circular material

The WAGO Green Range uses a bio-circular material that is residual from commercial or domestic processes. Regarding the PC material utilised in the housing of the connector, the bio-circular material comprises waste products from the management of paper and forests, leftovers from the manufacturing of vegetable oils, and recovered edible fat. WAGO encourages the reuse of by-products from other industries while simultaneously lowering its dependency on fossil fuels by employing these materials.

Sustainable packaging

Not only does WAGO use sustainable materials for its connectors, but it also prioritises environmentally friendly packaging. Grass paper packaging is a more environmentally friendly choice for the WAGO Green Range Splicing Connectors than 100% recycled paper packaging. Grass paper, which contains up to 30% grass fibre, is made by blending grass fibre with recycled paper. The production process uses less water and produces less CO2 than that of pure recycled paper. Additionally, because the grass fibre comes from ecological compensation sites that need to be mowed frequently and the clippings are used to make grass paper, its use promotes biodiversity.

Step towards a sustainable future

Sustainability is one of the growing trends that will have a crucial impact on the future. To create a greener environment, striving for more sustainable products is key. WAGO promotes a circular economy and reduces fossil fuel dependency with recycled and bio-circular materials. With the WAGO Green Range, customers can seamlessly transition to more eco-friendly practices while enjoying the same quality and certifications as the original 221 Series Splicing Connector. You can contribute to a more sustainable future by choosing more environmentally friendly products today – choose WAGO.