Connector reliability becomes critical in demanding industrial applications and harsh outdoor environments. These connectors serve as a lifeline, guaranteeing uninterrupted power and communication while shielding vital systems from the damaging effects of dust, water, and high temperatures. Bulgin, as one of the top producers of environmentally sealed components and connectors, provides connectors with IP67, IP68, and IP69K ratings made for harsh environments. This guide will examine the significance of such connectors to help you choose one that best suits your needs.

Understanding IP ratings for harsh environment connectors

Connectors with IP (Ingress Protection) ratings are intended for use in challenging environments. These ratings show how much water and solid object protection the connectors offer. Two digits make up the IP rating: the first indicates the level of protection against solid objects, and the second the level of protection against water. For example, an IP67 connector offers complete protection against dust and can submerge in water up to one metre for thirty minutes. Continue reading to learn more about IP67 connectors, as well as IP68 and IP69K connectors.

IP67 Connectors

IP67 connectors are made especially to offer strong protection against water and solid objects. Because they create a strong barrier that keeps out sand, dirt, and other small particles, they guarantee the security of internal electrical components. Moreover, water will not leak through these connectors when submerged in water to a certain depth.

Key features of IP67 connectors

- Dust and particle resistance: In order to provide dependable electrical connections in dusty conditions, IP67 connectors are made to keep dust and other microscopic particles out of the connector.

- Water resistance: perfect for outdoor and damp areas where splashes or rain are likely. They can withstand brief immersion in water up to one metre.

- Sealed design: To provide a tight and secure connection, IP67 connectors normally include a sealed shell that keeps moisture and debris out.

Industries utilising IP67 connectors

IP67 connectors are widely utilised in the following industries:

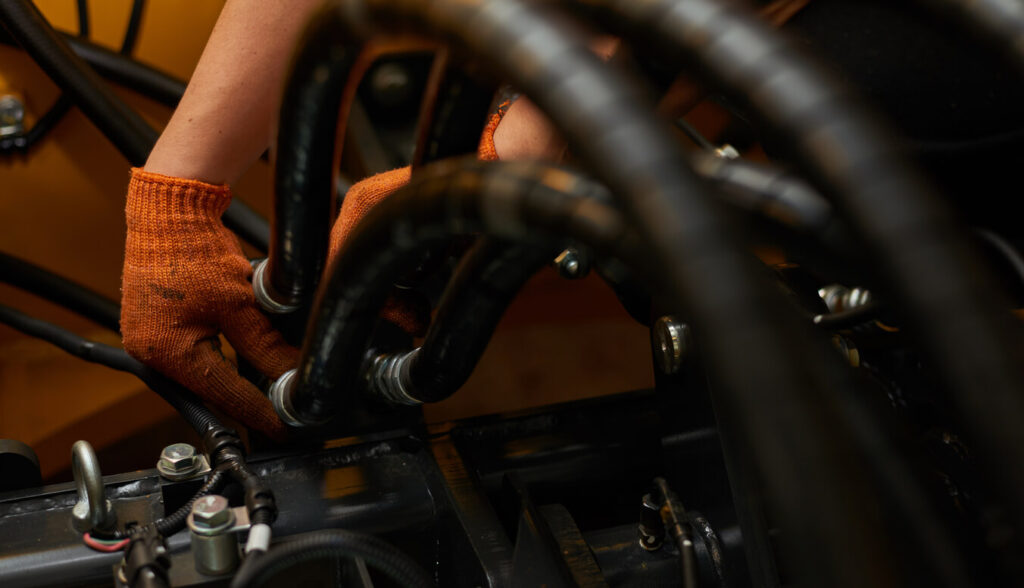

- Agricultural machinery – connectors in tractors, combines, and irrigation systems need to withstand exposure to dust, dirt, and moisture.

- Medical devices – surgical tools, diagnostic devices, and portable medical instruments rely on IP67 connectors to ensure reliable connections even in the presence of liquids.

- Mining equipment – for mining equipment, IP67 connectors are used in conveyor systems, drilling machines, and crushers to prevent dust and water infiltration.

- Automotive – IP67 connectors are essential in the automotive industry because they enable dependable connections in harsh conditions of manufacturing plant environments.

- Marine electronics – ideal for marine electronics, ensuring reliable and durable connections in harsh and corrosive marine environments.

- RVs and boats – IP67 connectors are vital for reliable electrical connections in recreational vehicles, campervans, and boats, particularly when exposed to outdoor settings.

Although IP67 connectors provide great protection, there may be instances where even higher defence is needed. Now, we move to IP68 connectors to find out whether or not they are appropriate for harsh environments.

IP68 Connectors

As opposed to IP67 connectors, IP68 connectors offer higher levels of protection. Not only can they withstand immersion in water up to 10 metres for two weeks, but they are also completely dustproof.

Key features of IP68 connectors

- Enhanced protection – offer a high level of protection against dust, dirt, and other tiny particles that could harm electrical connections.

- Water immersion – suitable for underwater cameras, sensors, and other equipment used in offshore oil and gas operations as well as other uses where complete water protection is needed.

- Chemical resistance – designed to withstand exposure to corrosive agents found in industrial settings, such as oils, solvents, chemicals, and other substances.

Industries benefiting from IP68 connectors

IP68 connectors are widely used in many different industries, including:

- Oil and gas: IP68 connections are necessary for underwater drilling systems, remotely operated valves, and underwater monitoring equipment to survive exposure to water, chemicals, and oil.

- Water treatment plants: connectors with IP68 rating are necessary for flow metres, water level sensors, and automated valves in water treatment facilities to ensure dependable connections in wet and submerged environments.

- Outdoor sports and wearables: necessary for fitness trackers, smartwatches, and action cameras in order to survive exposure to moisture, perspiration, and brief submersion in water.

- Military and aerospace: due to their ability to protect against water and dust, IP68 connectors are crucial parts of underwater drones, aerospace avionics, and military communication systems.

While IP68 connectors offer enhanced protection, there are circumstances where you need connectors that can withstand the most hostile environments. In such a scenario, you need the IP69K connector. Find out more about it and its unmatched toughness.

IP69K Connectors

IP69K connectors are designed to withstand direct water jets, high-pressure cleaning procedures, and complete dustproofing, enabling dependable operation in the most extreme conditions.

Key features of IP69K Connectors

- Defence against solid objects: connectors with the IP69K rating offer unparalleled defence against solid objects, making them suitable for applications in extremely abrasive conditions.

- Marine applications: Similarly to IP67 connectors, IP69K connectors are ideal for marine environments; they can withstand direct and powerful water jets.

- Chemical resistance: designed to withstand exposure to corrosive agents, cleaning chemicals, and high temperatures.

Industries utilising IP69K connectors

IP69K connectors, similarly to other IP-rating connectors, are widely used in many industries, such as:

- Food processing and beverage industries – food and beverage industry processing machines, conveyor systems, and automated packaging equipment uses IP69K connectors to withstand high-pressure and high-temperature cleaning techniques and still maintain dependable connections.

- Railway and transportation – connectors in exterior lighting, onboard electronics, and communications systems need to be robust to withstand regular cleaning.

- Pharmaceutical manufacturing – essential for chemical mixing and blending equipment, processing machines, and mixers to withstand rigorous cleaning procedures.

- Construction industry – excavators, bulldozers, loaders, and other heavy machinery in the construction industry require durable, sealed connections that can handle frequent cleaning and exposure to water.

Choosing the right IP-rated connector

When choosing a connector for harsh environments, several factors need to be considered:

- Specific requirements – determine the depth and duration of water submersion or the frequency of high-pressure cleaning needed for your application.

- Compatibility – check that the selected connector is compatible with your existing equipment and systems to prevent potential problems or conflicts.

By considering these factors, you can ensure the right connector for your application. However, if you still require assistance, Bulgin can help you with that! Reach out to Bulgin’s experts here to talk about your particular connectivity needs.

Bulgin: your trusted partner in harsh environment connectivity

Bulgin is a well-known brand in the industry for connectors meant for severe conditions. The brand provides an extensive lineup of connectors meticulously engineered to endure the harshest environments. Whether you need IP67, IP68, or IP69K connectors, Bulgin offers the ideal connectivity solution. You can guarantee the longevity, dependability, and safety of your vital systems by working with Bulgin as your partner.