Welcome to our IoT Coffee Chat where we have a talk about all things IoT Connectivity/Industry 4.0 over a cup of coffee with Hugo Neri

Hugo Neri Product Manager

I started with Crouzet 6 years ago in the R&D department later becoming Product Manager for North America. Since then I have progressed to become Product Manager for Crouzet’s entire Global Distribution Channel.

How did you get into your current role?

Several years ago whilst working as an R&D Engineer, I was invited to join the North American marketing team. I was surprised and initially I hesitated since I didn’t know what to expect from the marketing world but I told myself that I should give it a try. Now, several years later I haven’t regretted that choice at all and I’ve enjoyed working in this department as you are positioned as the interface between the field and the engineering department, looking to create the best products to meet our customers’ needs whilst applying the company’s growth strategy.

After doing an MBA in Marketing, I then received the invitation to move to Crouzet headquarters in France, where I now lead Product Management for the entire Global Distribution Channel.

How does your role involve you in the IoT connectivity/Industry 4.0 world?

As Product Manager I’m in charge of the new offers that enter via the distribution channel and as Industry 4.0 is the new trend in the market, I work to help Crouzet to be at the forefront of this new trend.

In your opinion, what’s the most exciting thing happening in IoT connectivity right now and why?

The field of predictive maintenance since the IoT can help not only to improve operating efficiencies, but also, if used correctly, can predict when a machine will likely enter into a dangerous operating condition or either breakdown before this happens thereby saving time and money.

What new products and technologies is Crouzet working with/on?

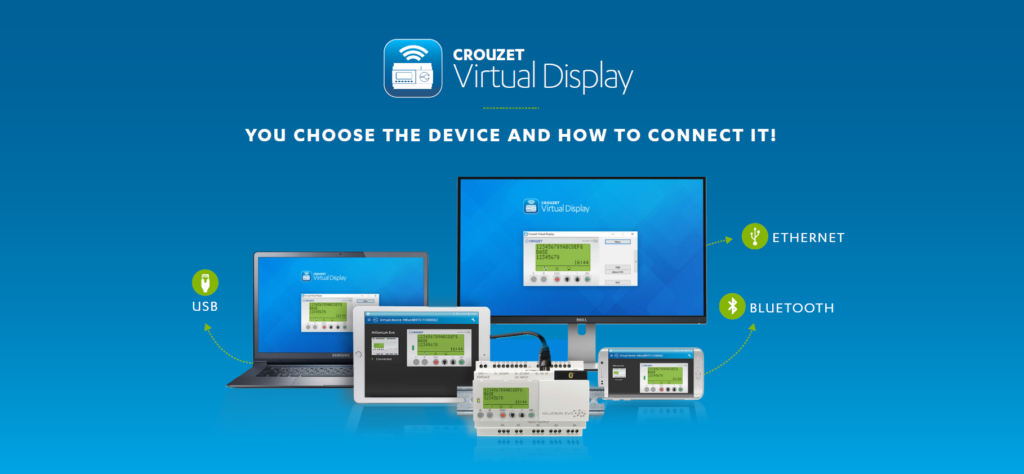

Devices that offer different types of connectivity to our customers so they can manage the data from the Crouzet devices as it’s most convenient to them. Particularly in the area of logic controllers like the Millenium EVO family, Nano-PLCs like the em4 family and Telecontrollers like the em4 Alert family, products that allow you to control, visualise and be controlled through several communication protocols. This is in conjunction with applications like Crouzet Virtual Display that can be installed in smartphones or laptops through different methods of connectivity. Besides that, a very strong point of Crouzet are the adaptation capabilities, where the products can really be tailor-made to the customer’s specific needs in terms of IoT.

What does the term “IoT connectivity” and “Industry 4.0” mean to you?

The possibility that the engineers can really be connected to their machines/applications through any type of communication, wherever they are and at any time. This allows the customer to pre-empt potential issues and increases the ability to react and ensure that everything runs correctly, benefiting everybody in the supply chain.

There are thousands of connected devices available. What’s your advice on selecting the right IoT connectivity/ Industry 4.0 solution(s)?

Identify what type of data you want to manage, how much information, and at what distance. For example, if you don’t need to manage huge amounts of data and it needs to be transferred at a short distance, devices with Bluetooth connectivity could be ideal. If you need to manage way more data and physical connection is not a problem, a device with Ethernet connection could be appropriate. If your device is in an isolated location without physical connection, a cellular connection could be the best option.

What factors should a company consider when selecting the right technology for IoT?

Interconnectivity, many platforms/devices can have connectivity but only with their own platforms/devices, and when having several components in a process/machine, it becomes difficult to manage all these platforms/devices especially when there is a cost associated with them. That is why, in order to simplify everything, the interconnectivity is an important consideration.

Why is choosing the right connectivity option so important?

Because there is so much at stake, for one side the correct operation of your machines/processes (that means the project success or failure), and for the other side the usage data of them.

Do you have any predictions as to how these technologies might evolve in the future?

I think these technologies will evolve into standardisation in the future. Just as other technologies that started with every player doing their things on their own and finally ended by standardising everything in order to make things easier to the customers. That’s why for Crouzet it is very important to offer the ability to adapt their products to whatever standard technology a customer is using/needing.