Electronic devices have a greater environmental impact than ever at a time when technology dominates in every part of human life.

Transforming electric devices into more environmentally friendly ones is a challenging task. However, there are many ways to accomplish this goal. In this article, we will discuss some of the ways by looking at how advancements in technology and responsible sourcing can lead to a greener tomorrow. Join us as we explore innovative solutions and practices that align with our commitment to sustainability, ensuring that every circuit, component, and device contributes positively to the environment.

The Environmental Challenges in Electronics Production

The manufacturing of electronic devices has a direct impact on the environment, from the extraction of resources to the disposal, energy consumption, and waste generation involved in the manufacturing process. According to Statista, it is anticipated that the amount of e-waste (electronic waste) generated will surpass 80 million metric tonnes by 2030, necessitating the need for enhanced infrastructure related to recycling and recovery.

Substantial quantities of metals and rare earth elements are needed for essential components like semiconductors, circuit boards, and batteries; yet, their extraction can result in serious ecological damage, including habitat destruction and water contamination. Furthermore, the energy-intensive production processes themselves frequently depend on non-renewable energy sources that release copious amounts of greenhouse gases into the atmosphere, exacerbating the issue of global climate change. The proper handling of electronics disposal, which is one of the waste streams with the highest global growth, is another crucial concern.

Hazardous chemicals and heavy metals leak into the environment as a result of improper disposal and insufficient recycling procedures, endangering ecosystems and human populations alike. In order to lessen the environmental impact of electronics manufacturing, addressing these issues will require a concentrated push towards sustainable manufacturing techniques, improved recycling technologies, and stronger regulatory frameworks.

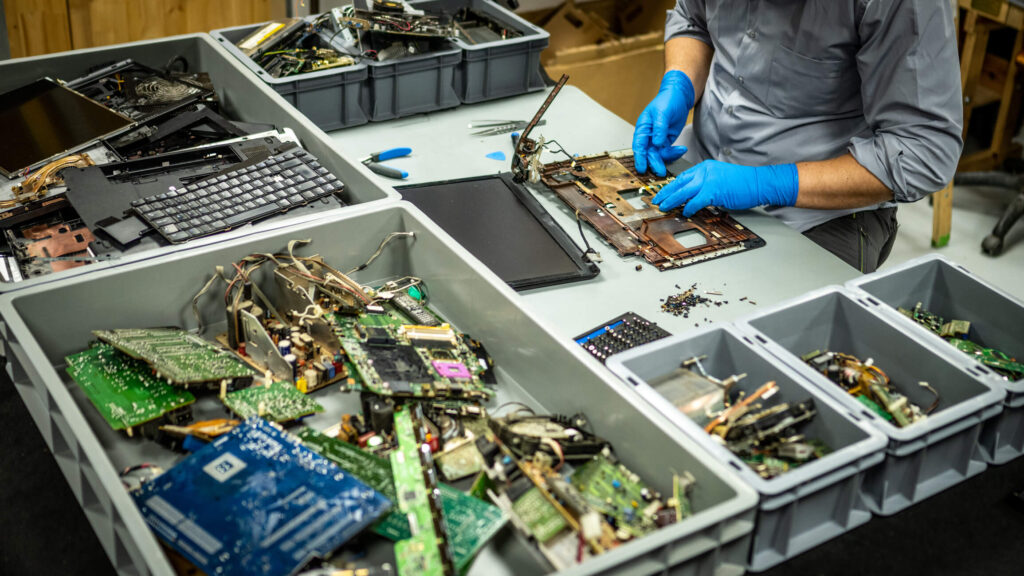

Electronics Waste Management

The world is trying to stop waste with zero waste initiatives, recycling programs and the use of renewable energy. This also concerns the electronic industry, which is trying to find a way to reuse and recycle electronic waste, which is, as defined by Britannica, ‘various forms of electric and electronic equipment that have ceased to be of value to their users or no longer satisfy their original purpose’, and is increasing at a rapid rate.

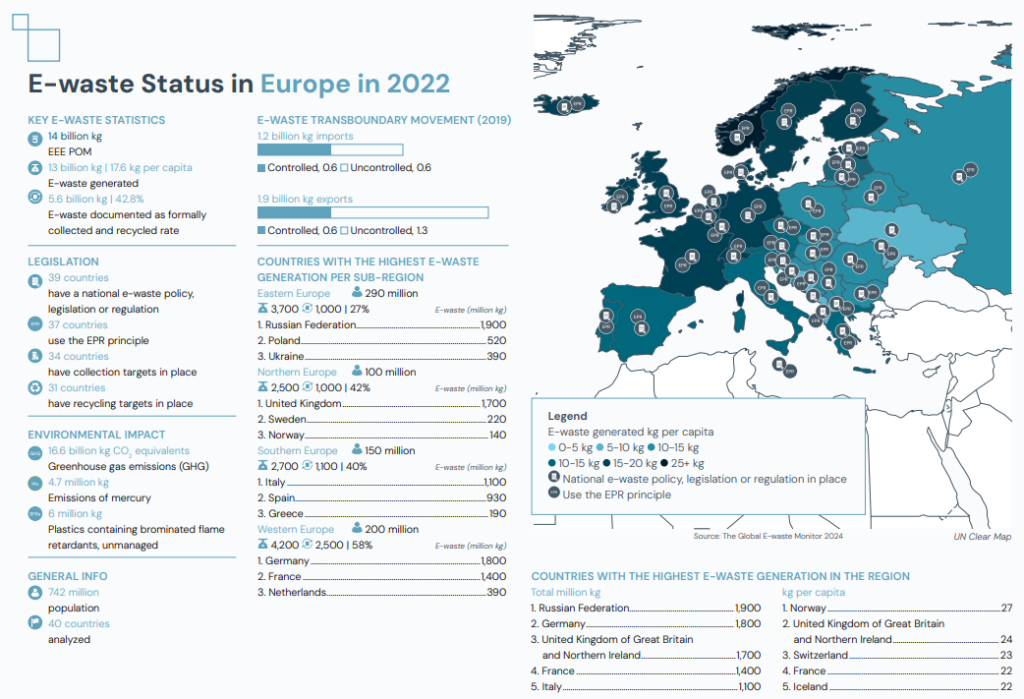

“Unmanaged e-waste has a direct impact on the environment and people’s health. Currently, 58 thousand kg of mercury and 45 million kg of plastics containing brominated flame retardants are released into the environment every year as a result of non-compliant management of e-waste.”

The Global E-Waste Monitor 2024, United Nations Institute for Training and Research (UNITAR)

As presented in the figure above, in Europe the countries with the highest e-waste rate are: Russia, Germany, the UK and France (2022). Nevertheless, according to the report, in terms of e-waste legislation and management, European nations—particularly those in the European Union—are considered ‘good examples’. The European Commision released the Critical Raw Materials Act in March 2023, acknowledging the necessity of enhancing the Union’s independence in the procurement of essential raw materials. The primary goal of the act is to guarantee the “secure and sustainable supply of critical raw materials”.

Therefore, the rise of e-waste worldwide emphasises the necessity of efficient electronics recycling programmes as well as the difficulties in managing these materials. A significant portion of the waste produced by end-of-life electronics contains hazardous materials that, if improperly disposed of, could seep into the environment. As such, it is critical to ensure that these materials are disposed of safely, and that new electronics are designed to be as environmentally friendly as possible. Besides e-waste recycling, there are several other ways to minimise the amount of electronic waste produced. Read on to find out more.

5 Best Practices for Reducing Electronic Waste

Reducing the environmental effects of electronics manufacturing calls for a multifaceted strategy that includes adjustments to customer behaviour, corporate social responsibility, and production techniques. Below, we describe some of the most important steps that can be taken to improve sustainability in the electronics industry:

Sustainable Design

It is crucial to reduce the environmental impact of electronics manufacturing by designing products with environmental considerations in mind. Products made from eco-friendly materials with a focus on reduced waste, energy efficiency, reduced recyclability and enhanced product longevity, are likely to have a lower environmental impact and decrease pollution.

“During product design, both small modifications and wholesale reinvention are reducing costs and waste.”

Deloitte, Sustainable manufacturing from vision to action

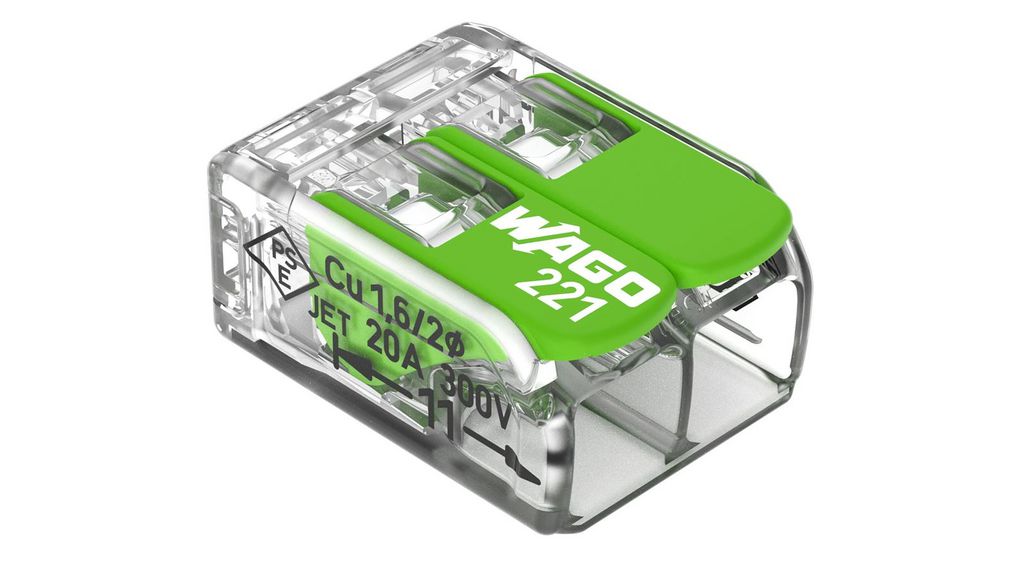

With a design for environment (DfE) approach, manufacturers can reduce the overall environmental impact of their products, processes, or services. An example of a brand that has made a commitment to sustainability is WAGO. WAGO reimagined one of its most popular products, the 221 splicing connector by creating an alternative version that is made partially bio-circular and from recycled plastics.

Green Manufacturing

Factories are the largest source of pollution in the electronics industry, but now the industry is moving towards greener smart factories, which are built with sustainable technologies. By implementing cleaner and more efficient production technology and utilising lean manufacturing practices to minimise waste output, enhancing energy efficiency, and utilising renewable energy sources, companies can reduce their carbon footprint.

Circular Economy

In contrast to the conventional “make, use, dispose” model, the circular economy in electronics places more emphasis on “reduce, reuse, recycle” focusing on designing goods for easy repair, extended lifespans, and effective recycling. This strategy lessens the negative effects of electronic waste on the environment by encouraging resource efficiency and lowering reliance on limited resources.

“[…] Implementing a circular strategy can lead to an estimated average of 12% in cost savings and 10% CO2e emissions reduction. Within each segment, we found that product-as-a-service and remanufacturing stood out as the best strategies across consumer electronics, industrial electronics, and ICT, depending on whether one aims to optimise for cost or CO2e reduction.”

PwC Sweden, Future Proofing the Electronics Industry: The case for circular business model, November 2023.

In addition, it satisfies growing consumer demand for sustainable products, helps global sustainability goals, and opens up new markets for recycling and refurbishing.

Regulatory Frameworks

To control the environmental effects of electronic products at every stage of their lifecycle—from the sourcing of materials to their disposal at the end of their useful life—stronger laws and standards are necessary. Governments can impose more stringent regulations on emissions and waste management, encourage the use of renewable energy sources, and fund the advancement of sustainable technology research and development. The Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive are the two primary European Directives that deal with electrical and electronic devices.

Consumer Awareness and Action

Demand for sustainable products may increase if people are informed about the effects electronics have on the environment and how to dispose of them properly. Raising awareness around the negative effects of electronic waste could lead to more consumer action in favour of sustainable electronics. Reducing the environmental impact can be achieved by picking more sustainable packages, purchasing greener electronics or refurbished products, promoting behaviours like extended device usage, and disposing of e-waste properly.

The Future of Green Electronics

It seems clear that green electronics will be crucial in creating a more sustainable environment as we move forward. Advancements in environmentally friendly materials, increased energy economy, and broad application of circular economy concepts are preparing the electronics sector for a revolution.

To fully achieve the potential of green technology and overcome obstacles, cross-sector collaboration and consistent effort are required. We can guarantee that the electronics of the future not only link us and improve our lives, but also protect the environment for coming generations by continuing to place a high priority on environmental responsibility alongside technological innovation. It is not only necessary, but also an opportunity to redefine progress in a way that is in harmony with Earth’s ecosystems, to embrace this green future.

At Distrelec, we recognise the crucial role that sustainable practices play not only in preserving our planet but also in shaping the future of the electronics industry. On our platform, KnowHow, we are committed to guiding and inspiring our community towards more environmentally friendly choices. Discover more of our sustainability-focused articles or go straight to the webshop to buy products from our green electronics range.

Recommended products

Power Supply GST120A Series, MEAN WELL

Splicing Connector, Wago

Solar PV Connector, Amphenol Industrial

Auxiliary Switch 4NO, Schneider Electric

Circuit Breaker 25A Poles=2, Siemens

Contactor 3NO 230V 9A 4kW, Siemens