Thermal imaging is an essential tool in HVAC maintenance and repairs. Much like medical imaging devices in the healthcare space (x-ray, MRI, etc.), thermal imaging can be used as a diagnostic and preventative tool for building maintenance. When used by experienced technicians, thermal imaging cameras can help diagnose HVAC system issues before they become significant problems. It is estimated that the average cost for HVAC replacement in 2021 runs between about 4,000 to 17,000 Euros; these are problems worth preventing.

How does it work exactly? These cameras display the infrared energy emitted by an object. The temperature of an object or substance determines the level of infrared energy that it emits. This allows thermal imaging cameras to show distinctions between hot and cold areas and use that information to solve problems accordingly. Here are top issues that thermal imaging can help identify:

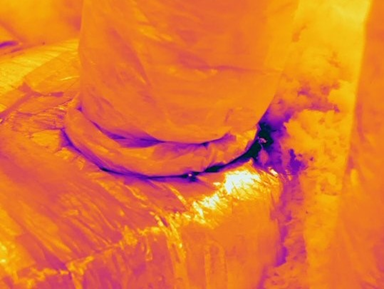

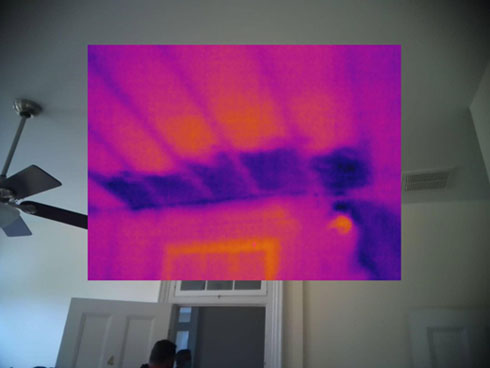

1. Identifying Airflow and Duct Leaks

The ability for thermal imaging to map temperature differences can be used to identify areas of airflow variation where it should be uniform. A trained professional can use this information to determine if an airflow problem or leak exists and recommend remedies or preventative measures.

In other words, thermal imaging can be a valuable tool to help you save money in both the short and long term. Heading off energy and airflow inefficiencies before they create operational costs or damages helps buildings remain occupied and active without disruption. Heat and airflow loss can create issues like ice dams, where snowmelt and temperature variances capture water with the potential to cause severe water damage. Or, when a building’s airflow creates an imbalance of air exchange, a building HVAC system can be overtaxed, leading to out-of-range temperature and humidity levels. The benefits of early detection provide opportunities to remedy issues quickly and run building systems efficiently with lower maintenance and energy costs.

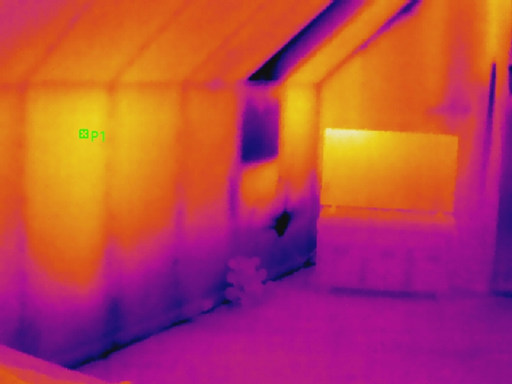

2. Building Envelope, Insulation, and Air Infiltration

Energy efficiency depends heavily on the integrity of a building’s envelope, including insulation, windows, and doors. Thermal imaging can help identify where climate-controlled air is escaping or where unconditioned air enters a building unintentionally. This allows for the implementation of repairs or upgrades that can improve the envelope’s insulation level.

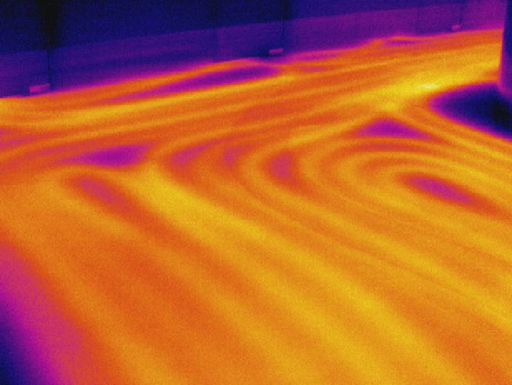

3. Locating Faults in Radiant Flooring

Radiant flooring is a great heating option because it’s consistent, comfortable, and relatively cost-effective. The downside is that the source of heating — tubing filled with liquid — is hidden behind or under finished surfaces. Any leaks or energy loss are hard to pinpoint without the use of thermal imaging. Thermal cameras allow home inspectors to examine the system without disturbing finishes.

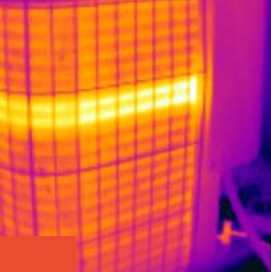

4. Diagnosing Condenser Coil Issues

In AC units, there can be several signs that coil components have been damaged or aren’t working correctly. Thermal imaging can help identify specific condenser coil issues. These variances might indicate problems such as blockages from debris, which can inhibit heat transfer and cause the unit to work harder.

5. Acting Fast to Overheating Electrical Connections

Fire and life safety devices can alert occupants when there is smoke, CO or fire situation. But thermal imaging can identify areas where electrical connections are in the process of overheating and could potentially lead to a fire hazard. Overheating of electrical or mechanical components can cause them to fail, disrupting occupancy or operations and creating expensive repairs.

6. Proactively Preventing Mould

In the past year, buildings have been at lower occupancy or unoccupied due to the pandemic, so water leaks and mould formation are primary concerns for building owners preparing to return to full occupancy. Thermal imaging can play a crucial role in getting ahead of mould problems before they start by helping identify areas with elevated humidity or condensation.

Finding these conditions early and before building conditioning systems are in full operating mode can provide facility managers with an opportunity to adjust HVAC settings or perform repairs before mould disrupts air quality and operational activities. Using thermal imaging can help identify areas where air temperature variances create excess humidity and potential growing conditions for mould within a building envelope or enclosed spaces.

The Bottom Line

As a skilled HVAC technician, you know that high-performance buildings, systems are often interconnected and interdependent. The ability to find and mediate inefficiencies through a building’s HVAC system can contribute to overall energy efficiency, especially in buildings where heating, cooling and plumbing systems exchange thermal energy. Thermal imaging can help you diagnose these problems faster. You’ll know the root of the problem sooner, so you can get to work fixing it faster.

The ability to stay ahead of potential energy or water issues is central to those in the field servicing efficient building systems. Fortunately, thermal imaging provides a non-invasive way to identify areas of energy loss and target leaks or other HVAC system weaknesses before they create damage or expenses.