Elektro-Automatik (EA) is a Europe’s leading supplier of power electronics in the automotive industry and across many other industries. EA develops and manufactures innovative power supplies in their German labs. EA now offers its ELR range of power supplies designed specifically to facilitate the testing of automotive fuel cells.

Fuel cells have been around for many years but with recent technological advancements and global initiatives for climate neutrality there has been a significant investment with automobile companies such as Honda, Toyota, Hyundai, and Mercedes.

Designing and manufacturing quality fuel cells requires characterizing the device and testing device performance. For standby power stations and automotive vehicles, fuel cells are assembled in stacks to meet the necessary power requirements for the application. These stacks can generate high power; thus, high wattage power supplies and electronic loads are needed for fuel cell characterization and testing.

Fuel cell stacks can deliver well over 10 kW of power. Elektro Automatik not only manufactures high-power DC supplies and loads, but these products have several features that simplify the task of simulating, characterizing, and testing fuel cells and make the testing more efficient.

What is a fuel cell?

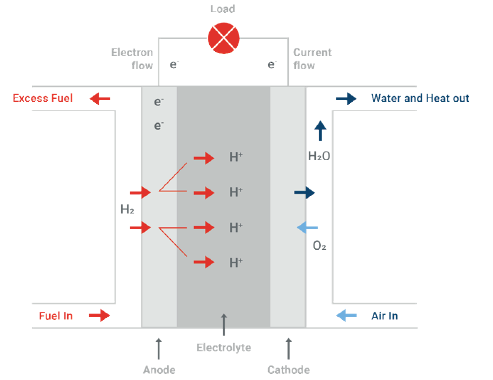

Before we talk about the testing of fuel cells, let us get a quick overview of what fuel cells are. Fuel cells are a chemical fuel. When a chemical reaction occurs it typically generates energy with a by-product such as heat. Most fuel cells are often hydrogen based mixed with an oxidising agent such as oxygen which then creates electrolytes.

The advantage of using hydrogen is that the by-product of the chemical reaction is just heat and water vapor making it a clean energy to use. Hydrogen used in the fuel cells can be harvested by several ways, steam methane reforming of fossil gas, biomass gasification, electrolysis of water or solar thermochemistry.

There are several diverse types of fuel cell designs, but they all consist of the same elements; an anode, a cathode and an electrolyte that allows ions that move between two sides of the fuel cell as shown in Figure 1.

How do you test for corrosion resistance?

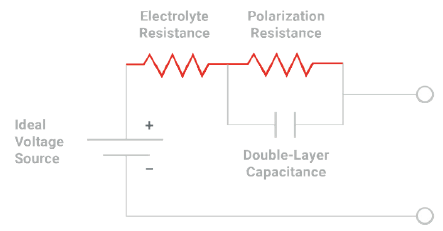

The most important parameter of a fuel cell is its resistive component. The electrolyte resistance is the main contributor to the total resistance of the fuel cell. The polarization resistance models the reaction equivalent resistance, and the double layer capacitance models the anode-electrolyte-cathode interfaces. The lower the total resistance of the fuel cell is, the lower is its power loss and its efficiency is higher.

With power generation of kW to MW, an excessively high total resistance can prevent a fuel cell stack from outputting its maximum rated power.

The difficulty with measuring the resistance of the fuel cell is due to fact that the cell voltage source cannot be isolated from the resistive components as the circuit model might suggest. Rather than employing a conventional DC resistance measurement, the measurement of fuel cell resistance requires an AC measurement.

The pseudo-AC measurement is known as the current interrupt method. This method, as the name describes, creates a current by instantaneously switching the load current from a steady state value to 0 A. The fuel cell voltage rises to its open circuit voltage from the voltage reduced by the product of the load current and the fuel cell resistance.

So how do you create the current needed to characterize the fuel cell? You need an electronic load and the ability to vary its constant current output with an AC signal of varying frequency. You could connect the load and a waveform generator together. Waveform generators are low power devices, so you would have a problem testing a fuel cell stack containing several fuel cells. You could connect the waveform generator through a bias-T to the electronic load; but bias-Ts are low power components used primarily for RF applications. Connecting a low power waveform generator to a high-power electronic load is a challenge.

EA solves that challenge with their ELR electronic loads by integrating the waveform generator into the load. You do not have to worry about external connections and protecting a waveform generator from damaging high power. The waveform generator outputs sine waves, triangle waves, square waves, trapezoidal waves, ramps, and arbitrary waveforms. With the ELR load, you can create any type of dynamic load including a sinusoidal perturbation on a DC current sink for fuel cell resistance characterization.

In addition, the ELR load, with its internal waveform generator can subject the fuel-cell-under-test to a wide range of dynamic load variations for both performance and durability testing. The load can stress a fuel cell with large step load changes at varying duty cycles.

Simulating a Fuel Cell for Realistic Inverter or DC-DC Converter Testing

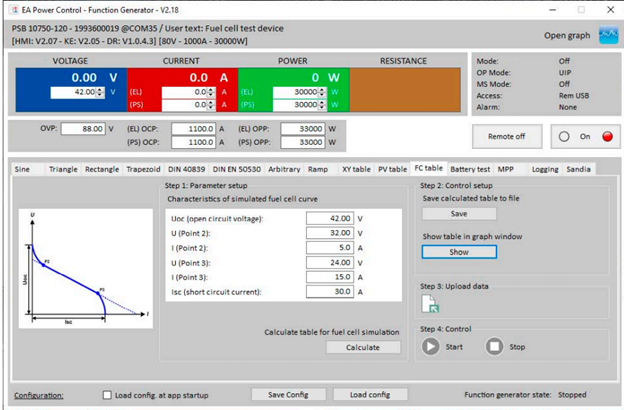

Now that the fuel cell is characterized, the PSB-series power supplies, which also have a built-in waveform function generator, can simulate the output of a fuel cell. Using the simulated fuel cell, an inverter for a device such as a standby power source or a DC-DC converter for an automotive vehicle can be tested under the most realistic conditions. Just use the Function Generator Application in the Elektro Automatik Power Control Software. Enter the key voltage and current parameters, and the Function Generator App enables the PSB power supply to emulate the output of your fuel cell stack.

Figure 3 shows the window for the Fuel Cell table which shows the fuel cell characteristic V-I curve and defines the fuel cell output. At maximum voltage, fuel cell output is dominated by electro-kinetic effects. In the central part of the curve, the linear, ohmic resistance of the fuel cell determines the output characteristics. At the high current-low voltage portion of the curve, the exponential characteristic is defined by energy being consumed at a faster rate than hydrogen and oxygen can diffuse to the anode and cathode to supply energy.

The simulated fuel cell output can test inverter or DC-DC performance as these loads draw both low current and high current. The results indicate how well the loads can maintain their output under the varying voltage of the fuel cell. Fortunately, you do not need a complex test setup with an external variable resistance for testing inverters and DC-DC converters. All you need is a PSB-series power supply.

Save energy and run cooler

Both the ELR series electronic loads and the PSB series bidirectional (source and sink) power supplies can absorb power and deliver it back to the power grid with an outstanding 96% efficiency. When you use the ELR loads or the sinking function of the PSB supplies, efficient inverters in the two instruments provide the regenerative energy recovery to reduce your electric utility costs. Returning the absorbed energy to the grid saves on cooling requirements for these instruments which can output and sink up to 30 kW. The instruments need lower capacity fans which run more quietly and less cooling infrastructure to maintain them at a safe operating temperature. Benefit from lower utility costs and the knowledge that you are helping the environment.

Work in any automated test environment

The Elektro Automatik PSB power supplies and ELR loads offer several interfaces to allow easy communication and control in a few test environments The PSB Series supplies and the ELR loads have USB and ethernet as standard interfaces for simplified connection to a PC. With optional ModBus and Profibus interfaces, the instruments conveniently allow control by a programmable logic controller (PLC). With the CAN interface, the instruments can interface to an automotive control system. That is more flexibility than you get from other power supply and electronic load manufacturers.

Summary

Fuel testing is a complex process which can be made easy with the right tools. Elektro Automatik are industry leaders in power electronics and offer several solutions for the testing of fuel cells within the automotive market. Specifically, hydrogen fuel cells are considered as one of the cleanest fuels you can use with little to no carbon emissions. It is essential to ensure their longevity and efficiency during operation and storage by regular testing of the fuel cells across a number of industries, including automotive.

Electronic Loads EL 9000 B

Electronic Load EL 3000 & EL 9000 Series

Electronic Load ELR 9000

Bidirectional DC Power Supplies, EA-PSB 9000