Choosing the right signalling device for your application can be difficult, since signalling devices differ in functionality, design and colour. This article will give you advice on different possibilities, whether you want to replace an existing system or get a completely new signal device.

You will get the support to choose the right signalling equipment from one of the world’s leading manufacturers of signalling devices – Auer Signal. The brand has been on the market since 1910. By inspiring customers with innovation, Auer Signal is constantly working on new product developments. Discover some of these innovations today.

In this article, you will find answers to the following questions:

- What are signalling devices?

- What are the types of signalling devices and warnings?

- How or where should the signalling device be installed?

- What are the environmental conditions for installing a signalling device?

- Which lighting function is required?

- What is the colour purpose and signal loudness?

- What supply voltage does your application require?

- What are the safety requirements?

Know-how to signalling devices

Knowing which signal solution is optimal for a certain application is difficult and requires a certain level of expertise. In order to assist you in choosing the best signalling solution, below you can find some essentials.

Signalling devices in brief

An industrial facility needs an effective low-level visual and audible communication system to properly operate. Therefore, there are signalling devices which main purpose is to convey information about a machinery status, manufacturing lines or industrial equipment in a safe, accurate, and effective manner. They can also flag a potentially dangerous circumstance. Put simply, a signalling device is nothing more than a tool that activates an alarm, which may be audible or visible depending on the chosen type and the control panel trigger. They are usually linked in a control panel. You can read more about it in our interview with Auer Signal’s Sales Manager.

Different types of signalling devices and warnings

Depending on the circumstances, you might need a device to communicate that something dangerous has happened, display an operating condition or just notify without the need to communicate verbally. In some situations, the form of signalling is predetermined by rules and regulations (see EU machinery directive) but mainly, the acceptable type of signalling depends on the conditions of the workplace.

Depending on the purpose, whether it is indicating hazards, operation or just informing, there are different types of signalling devices, such as:

Audible signalling devices

Audible signalling devices, also called acoustic, inform about an incident or possible dangers. They have a loud signal tone available in various forms, from a buzzer, siren, continuous or intermittent sound to a bell. When choosing the acoustic signal device, you should consider not only the intensity of the sound and method of signalling but also the IP rating and operating temperature.

Optical signalling devices

Lamps and signal columns (also known as signal towers) are among the optical signalling equipment that is most often used. They are available in red, yellow, orange and green colours and are suitable for the non-verbal transmission of information. They are similar to traffic lights and mainly used for status and operation indication of plants, production machines or in control cabinets. In addition to being employed as parts of industrial signalling systems in manufacturing facilities, lights and columns may also be used in logistics, transportation, sports, or public facilities, such as in access control systems.

Signalling devices in the form of signalling lights are straightforward optical warning tools with a strong light source, often an LED, halogen, or xenon lamp. The various light sources have distinct levels of power consumption, luminous efficacy specifications, and preferred radiation angles. However, the worldwide standard is signalling lights with LED technology. LED signalling devices usually do not require maintenance or any other electrical services after installation. Therefore, all of Auer Signal’s products are equipped with LED technology. However, some individual models can be found in conventional xenon technology.

Auer Signal offers two different types of signal towers: modular and compact. Modular signal columns provide variable version selection that is perfectly suited to the requirements and unique features of the workplace. You may freely choose the signalling light colours and optionally add or delete various components when selecting these devices. The modular signal columns also make simple construction, disassembly, and potential system extension possible.

Compact signal columns are pre-made, pre-programmed solutions. An example of a compact signal tower is the Auer Signal HD90-Q81 model, available to see and purchase from the Distrelec webshop.

Visual-audible devices

Mainly used in signalling systems, technical installations, industry and special applications, for example, when the optical signal alone is not sufficient or when double signalling is required. The acoustic indicator draws additional attention to the status of the visual signalling apparatus.

The visual-audible combination is dependent on some other factors, such as the signalling units, the amount of space available, the range of functions (light functions, sound types), and the power (light intensity, volume) needed by the two devices.

Additionally, when selecting the right signalling system, it is important to know the power supply voltage (see below) and electricity consumption.

Supply voltage for your application

Usually, the signalling device already specifies the necessary supply voltage. They can be grouped into low and main voltages, depending on the application:

Low voltage

- 12V – suitable for mobile work devices and vehicles.

- 24V – most common in machine and control cabinet construction. Referred to as a control voltage, as in most devices, the control voltage is 24V.

- 48V – suitable for country-specific applications, especially common in France and Australia.

Main voltage

Main voltages are often used in buildings or building services. It works well when there is no need to install an additional power supply unit. The available voltages are 110V, 115V, 220V, 230V, and 240V.

Installation of signalling device

There are a lot of aspects that need to be considered before starting an installation of a signalling device. The crucial aspect is the mounting type.

Types of mounting

- Horizontal – mounted on a horizontal surface means that the device’s directional characteristics (frontal or lateral) or the sound emission (directional or omnidirectional) determine the signal effect.

- Vertical – vertical positioning means that the signal perception may vary based on the directional feature or sound emission.

- Vertical using brackets – there might be mounting brackets needed when the signal device is not installed directly on the wall or surface but rather is positioned horizontally on a vertical mounting surface. The bracket ensures that the signalling effect is perpendicular to the mounting surface.

- Pole mount – signalling equipment mounted on poles is more visible since it stands out from its surroundings, and that way, it is easier to see even from a distance. Acoustic devices with omnidirectional sound propagation are also employed for pole mounting.

- Ceiling – ceiling mounting is used when horizontal mounting does not provide the signalling effect. Directly mounting to the ceiling helps ensure that the signalling device’s reach is not covered by any other installations or objects, e.g. shelves. The ceiling installation enables the audio signalling devices to be in a broader area.

- Panel mount – the signalling equipment is either put directly on a device or integrated inside a device, for example, in a control cabinet or control panel or directly on a device, like robots or machines. Most installations include a straightforward single-hole mounting method (M22 screw thread). Also, panel mounting is most suited for signalling at a close range of roughly 5 metres.

Environment

Other factors that contribute to the correct installation are environmental conditions. For example, the installation on a pole is particularly inappropriate in a highly vibrating environment since the pole will act as a conduit for the extremely strong vibration to reach the signal device. As a result, the signal device should be positioned closer to the surface, the stronger the ambient vibrations.

Depending on where the signalling device will be installed, different protection should be considered:

- For outdoor signalling – the signalling device has to be protected or covered, as rain and direct sunlight might impact the efficiency of the device. Auer Signal produces lenses and plastic parts made from UV-stabilised polycarbonate which protect the device against fading due to extreme sunlight.

- For indoor signalling – for signal light used in highly flammable, combustible or explosive environments, the signal devices should have explosion protection.

Also, do not forget to check if the surface is suitable. If the signalling device is positioned on a delicate surface, such as one that has to be protected against water penetration, there might be a flat gasket necessary.

Lighting function requirements

Depending on the purpose and application, signal lights can have a different range of certain lighting functions. Here are examples:

Strobe beacon

The strobe beacon is the most popular one among all signalling lamps. It is an ideal hazard warning and is often installed on machines to signal failures and keep the downtime as short as possible. The strobe lights can also warn of dangers, like gas leaks.

Flashing beacon

A flashing beacon is the right choice to signal faulty conditions, especially in circumstances where there is a need for action but no danger, for example, filing up machines. They light up evenly and are required where the signalling device is well visible, for example, on a machine or plant.

Multifunction beacon

Multifunction beacon, as its name indicates, offers multiple light functions. The different functions and requirements can be adapted depending on the needs and purpose. Some offer pulsating light, rotating light and dimming functions.

Steady beacon

Steady beacons are used to indicate the (normal) status of a device or machine, for instance, a green light for free passage of the mode of transport or the operation of the machine.

Multicolor beacon

Multicolor beacon lights signalise multiple statuses thanks to many different colours. Auer Signal offers multicolour beacons that can show two to seven different colours. Different operating statuses can be alternately shown with just one beacon, removing the need for additional signalling hardware.

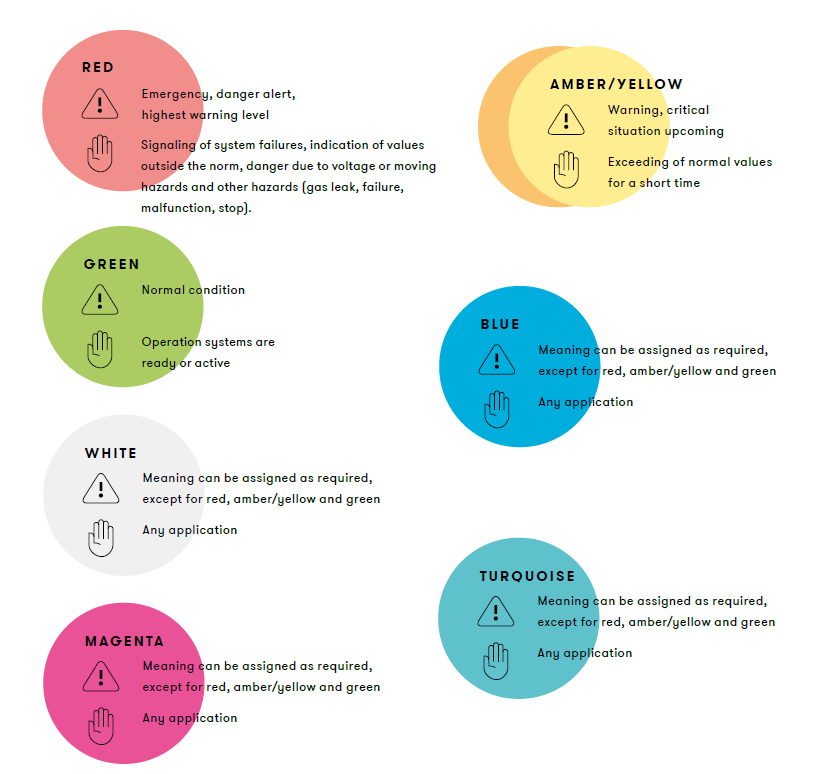

Colour purpose for visual signalling

Each colour indicates something different, so it is crucial to select properly. Some signal colours are more appropriate for visual signalling than others, depending on the purpose and area of use. The observer has to act immediately after seeing the colour signal. The reaction, however, can differ depending on the colour of the signal light.

The decibel level or light intensity often becomes increasingly important as the signalling device, and receiver distance grows. This indicates that when the signalling range increases, a signalling device must be brighter or louder. Read more about the acoustic signal loudness below.

The most common colours in signalling devices are red, yellow, green, blue and white. Additional to the standard ones are turquoise and magenta.

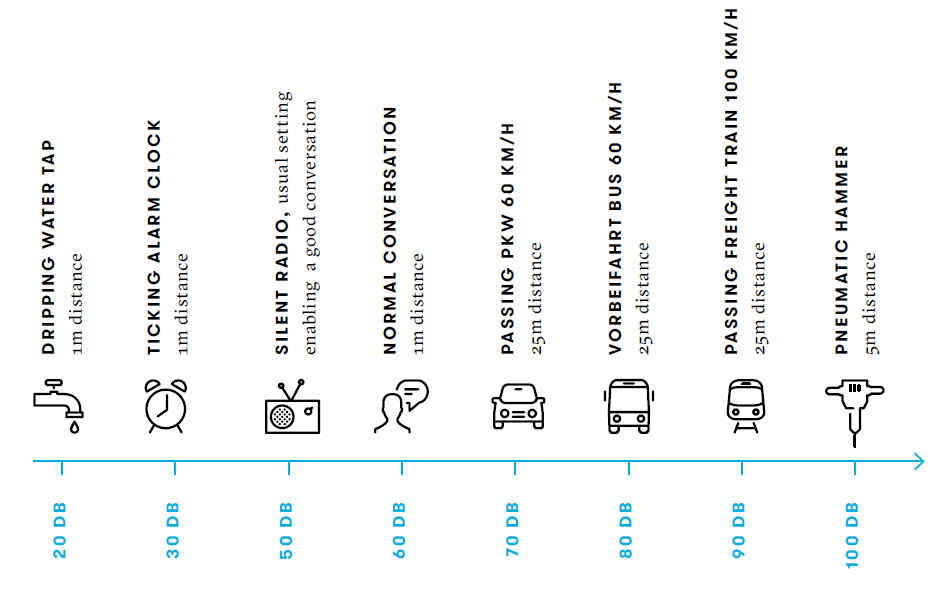

Acoustic signal loudness

Acoustic signalling equipment is typically used to alert people to potential dangers. Depending on whether the transducer will be located outdoors or indoors, there are different requirements for which acoustic signalling device to choose. To communicate about a warning they have a loud signal tone but some disruptions might cause the sound to be quieter, mainly environmental changes, such as wind speed and direction, humidity and general weather conditions, so it should be considered that the table just shows approximate values.

To measure the ambient noise, often a sound level meter can be used.

Protection and safety

The IEC 60529 IP rating describes the level of protection for electrical equipment. In this case, protection of signalling devices against the impacts of solid foreign objects and against liquids in housing or coverings.

The most common abbreviations for Auer Signal products are IP66 and IP67.

Certifications and markings for your signal device

Certifications for signalling devices are mainly described by law or a requirement of the market. For example, for the European Economic Area, all signalling devices must have the CE UKCA (UK Conformity Assessed) marking, whereas the UL certification is one of the most important certifications in the field of product safety and plays a major role in the North American market.

You can find more information on the Auer Signal website and in data sheets, here.

3 steps to buy the right signalling device

- Compatibility – check the compatibility of the design with the existing signalling device. At Auer Signal, you can use detailed 3D models of the signalling devices to ensure that you are choosing the right one.

- Electrical planning – similar to the compatibility of the design, the existing connections and the power consumption should be checked.

- Start the device – after checking if the signalling device fits and the planning process and equipment are completed, the device is ready to start. Therefore, bear in mind that only experienced electricians should install signalling devices.

Auer Signal – high-quality signalling equipment

Auer Singal’s products are created, tested, and manufactured in Austria to the highest industrial standards. By exploring our webshop you can buy the equipment mentioned earlier, including signal lights, signal beacons, constant beacons, flashing beacons, strobe beacons, and multipurpose beacons with accessories, including audible signal devices, such as sirens and horns.

Additionally, Auer Signal can develop and produce customised signalling devices, such as self-configurable tower stack lights, in compact or modular types. This service includes everything from entirely autonomous product creation to adaptation to a customer-specific product design, as well as customised cabling and mounting kinds. Auer Signal is an expert in custom-made signalling devices for special applications in a wide range of industrial markets, including plant construction, logistics facilities, mechanical engineering & automation, switch cabinet & crane construction, control technology, building services, and security for door and gate access.

Source: Auer Signal