The development of new technologies contributed to many industrial revolutions. One that opened up vast opportunities for controlling machines and improving the factory plants is Industry 4.0. Among others, the wireless solutions had the impact that contributed to the revolution.

Wireless technology is one of the most widely used in manufacturing today, with benefits felt throughout the value chain. In smart manufacturing, sensing technology allows for continuous asset monitoring where wireless networks eliminate the installation and maintenance costs associated with wired solutions.

The Role of Wireless Solutions in Industry 4.0

In the fourth revolution, wireless systems facilitate data transfer from one location to another. They allow for greater data transmission. Wireless networks have always fueled smart production, starting with 4G and subsequently shifting to 5G. The 5G is the next generation of mobile communication technology that offers higher speed, advanced analytics and big data.

Wireless devices connect equipment that needs to move around freely and allow for machine-to-machine connectivity. The wireless solutions are in almost all sectors of the factory floor. It covers development to production, as well as storage and distribution. It also helps solve the issues that come in any of these processes. Thanks to that, the response for instructions in robotics and automation is under control. It is especially important because soon, many factories will move from Industry 4.0 to Industry 5.0, where the cooperation between robots and humans will play the biggest role.

The key factors to global mobile traffic growth are wireless devices’ ever-changing mix and growth. According to Cisco research, by 2023, 8.7 billion portable or personal mobile-ready gadgets will be in use. Between 2018 and 2023, North America and Western Europe will have the highest growth in mobile devices and connections, with CAGRs of 16% and 11%.

Benefits of Wireless Connectivity

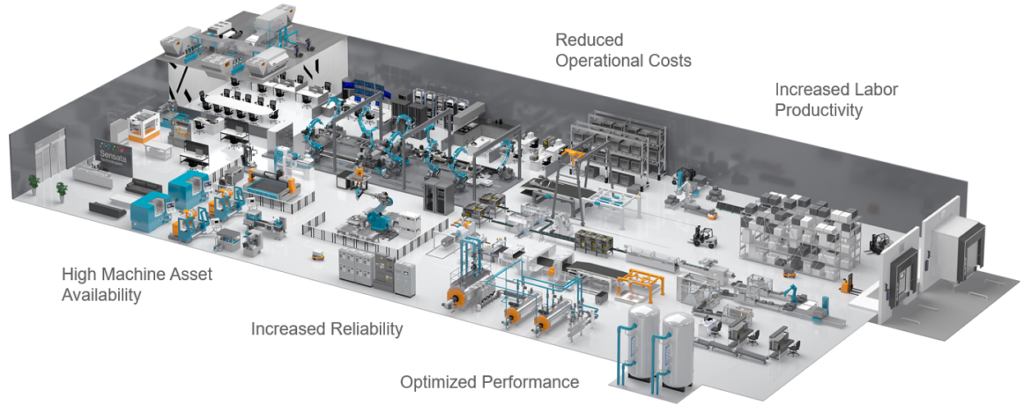

With a rising number of manufacturing companies seeing the benefits of wireless technology, its adoption is only anticipated to grow. As per Sensata, there are five main wireless connectivity benefits that smart factories gain:

- Optimise performance.

- Increase productivity

- Reduce costs

- Increase plant’s reliability

- Increase machine assets

Optimised performance

Now with the industrial revolutions growing, the capabilities of factories are changing. Optimising the manufacturing floor can help produce faster and better products. Wireless sensors and systems integrated into automation equipment enable precise control. The system delivers data wherever the process changes. The speedy response aids in the operation and performance of the company.

Increased productivity

Factories with only a few automation systems are working way slower than smart factories. The manufacturing equipment that is based on wireless technology can improve the factory plant by working longer and more efficiently. Thanks to automation, this can also remove route-based maintenance and manual tasks.

Reduced costs

Wireless solutions help automation systems run as efficiently as possible, generating little waste heat, utilising the least amount of power, and maximising all plant resources. Because wireless solutions function on low voltage, they can also eliminate the requirement for electricians. Manufacturing becomes more cost-effective and productive as a result of all of this.

Increase plant’s reliability

Wireless communication can replace material and labour costs and remove long and intricate wiring runs. Plants become more reliable as a result of the combination of these factors. The reliability works on an increase in production and finally benefits the company.

Increased machine assets

The profitability grows when machines are in use. Factories with little availability and low production times cannot achieve high performance. To avoid downtimes, it is important to invest in wireless connectivity.

The new industrial revolution is driven by wireless connectivity

In the era of innovations transforming outdated plants into digital factories should start as soon as possible. With the growth of industry 4.0 and the advent of the IoT, industries are going through some changes, mostly digitalisation. Businesses that stay behind with production and do not keep up with the changes will not succeed. The wireless connection is driving the industrial revolution with components, such as sensors, machines and other devices waiting to be connected.

Examples can be new Human Machine Interfaces (HMIs) that use augmented and virtual reality. They need to meet the same requirements for delivering high-resolution visuals and quickly responding to the user’s gestures. Besides that, mobile robots require ultra-reliable, low-latency connectivity and a high-fidelity data line. Also, sensors need to connect with other sensors or machines and be able to work consistently in crowded environments. All of these devices need wireless capabilities.