Pneumatics is an essential component of the ever-evolving field of industrial automation and control, enabling accuracy and efficiency in a wide range of applications. Its consumables, the sometimes disregarded but crucial parts that guarantee the efficient operation of pneumatic systems, are the foundation of this pneumatic power. These components, such as tubing and fittings, supply the force and movement required to keep our industries operating. They are the unsung heroes of manufacturing lines, robotic arms, automotive assembly, and packaging machinery.

This article focuses on the world of pneumatic tubings and fittings, guiding you through what they are, the different types of products used and how to choose the right one for your application. Anyone working in engineering, design, or maintenance in an industry where pneumatics are common should be aware of these components. If you want to know more about pneumatics tubing and fittings, you’re in the right place.

What is Pneumatics?

Pneumatics is a branch of engineering that involves the use of gas or pressurised air to effect mechanical motion. Pneumatics principles are frequently used in systems that use inert gases, such as compressed air, to run different kinds of machinery and equipment. Here is a lowdown of the major things to know about pneumatics:

- Working Principle – The idea behind pneumatic systems is that compressed gas expands and applies force to a piston or diaphragm inside a cylinder. Movement is fueled by this expansion and can be used to perform tasks like lifting, moving, or clamping objects.

- Components – As well as various connectors and tubing, typical parts of a pneumatic system include an actuator or cylinder (which turns air pressure into mechanical motion), valves (which regulate air-flow) and air treatment parts (such as filters, dryers, and regulators to prepare the air).

- Applications – A wide range of industries make extensive use of pneumatic technology. Pneumatics powers equipment used in automation and manufacturing, such as robotic arms, assembly systems, and conveyor belts. It’s also used in tools like air hammers, drills, and wrenches. Other applications include braking systems in vehicles, particularly trains and buses, and various control systems.

What are Pneumatics Tubing and Fittings?

A pneumatic system requires pneumatic tubing and fittings in order to connect its various components and deliver compressed air to its required locations. Let’s take a look at both types of components:

Pneumatic Tubing

Pneumatic tubing is flexible piping designed to carry compressed air from one component of a pneumatic system to another. It’s the conduit that ensures air flows efficiently and safely to the points where it’s required. It’s usually made from materials like polyurethane and polyamide (nylon), chosen for their durability, flexibility, and resistance to wear, moisture, and chemicals. To accommodate varying pressure levels and flow rates, tubing is available in a range of diameters and lengths. It can be straight or coiled; coiled hoses work well in situations where space conservation and mobility are top concerns. RND offers pneumatic tubing in a range of lengths, from as small as 20m to 200m. Check out some of the tubing the brand offers below:

RND Pneumatic Polyurethane Tubing, 20m

Features:

- Ester-based PU tube

- Excellent pressure resistance

- Weather resistance

- Corrosion resistance and flexibility

Applications:

- Industrial automation

- Pneumatic tools

- Tube for water and fluids

- Vacuum tubes

- Protective sleeve for metal and electronic products

RND Pneumatic Polyamide Tubing, 100m

Features:

- Excellent pressure resistance

- Weather resistance

- Corrosion & vibration resistance

- Typical applications include: Industrial automation, Pneumatic tools

RND Pneumatic Polyamide Tubing, 200m

Features:

- Excellent pressure resistance

- Weather resistance

- Corrosion & vibration resistance

- Typical applications include: Industrial automation, Pneumatic tools

How to Choose the Right Pneumatic Tubing for Your Application

Selecting the appropriate pneumatic tubing for your application is essential to ensure that the system operates effectively, dependably, and safely. When choosing pneumatic tubing, keep the following important factors in mind:

- Operating pressure: Find out what pressure your pneumatic system can run at its maximum. This pressure must be sustained by the tubing without running the risk of bursting. Verify that the tubing’s pressure rating satisfies or surpasses the specifications of your system.

- Tubing size and length:

- Length: Longer runs of tubing can result in pressure drops. However, longer lengths of tubing have the advantage of giving the customer more freedom to cut the tube to precisely fit the application. This reduces the need for joint connectors.

- Diameter: The tubing’s inner diameter should correspond to the flow requirements of your system. A diameter that is too large may cause slower air movement, which will lessen the effectiveness of actuators, while a diameter that is too small may restrict flow and reduce efficiency.

- Environment: Consider environmental factors like humidity, temperature, and exposure to substances like oils, chemicals, or UV radiation. Diverse materials provide differing degrees of resilience against these circumstances. For instance, nylon is well-known for its high-pressure rating and temperature resistance, whereas polyurethane is resistant to oil and kinks.

- Connection type: Verify that the tubing fits the fittings and connectors that are utilised in your system. To avoid leaks, the tubing needs to fit these parts tightly and securely.

- Flexibility and bend radius: The tubing’s bend radius gives an indication of when the tube is most likely to kink and restrict flow. It is helpful to account for the bend radius when routing tubing along a specific path or in a tight workspace. Using an alternative fitting is one way to deal with this.

- Material compatibility: The material required for your tubing will often depend on your application. The tubing you choose will depend on whether it will be used for medical purposes, food and drink, or contact with potable water. Look for “medical-grade tubing (USP VI),” “FDA Approved,” or “NSF Certified” for these particular examples.

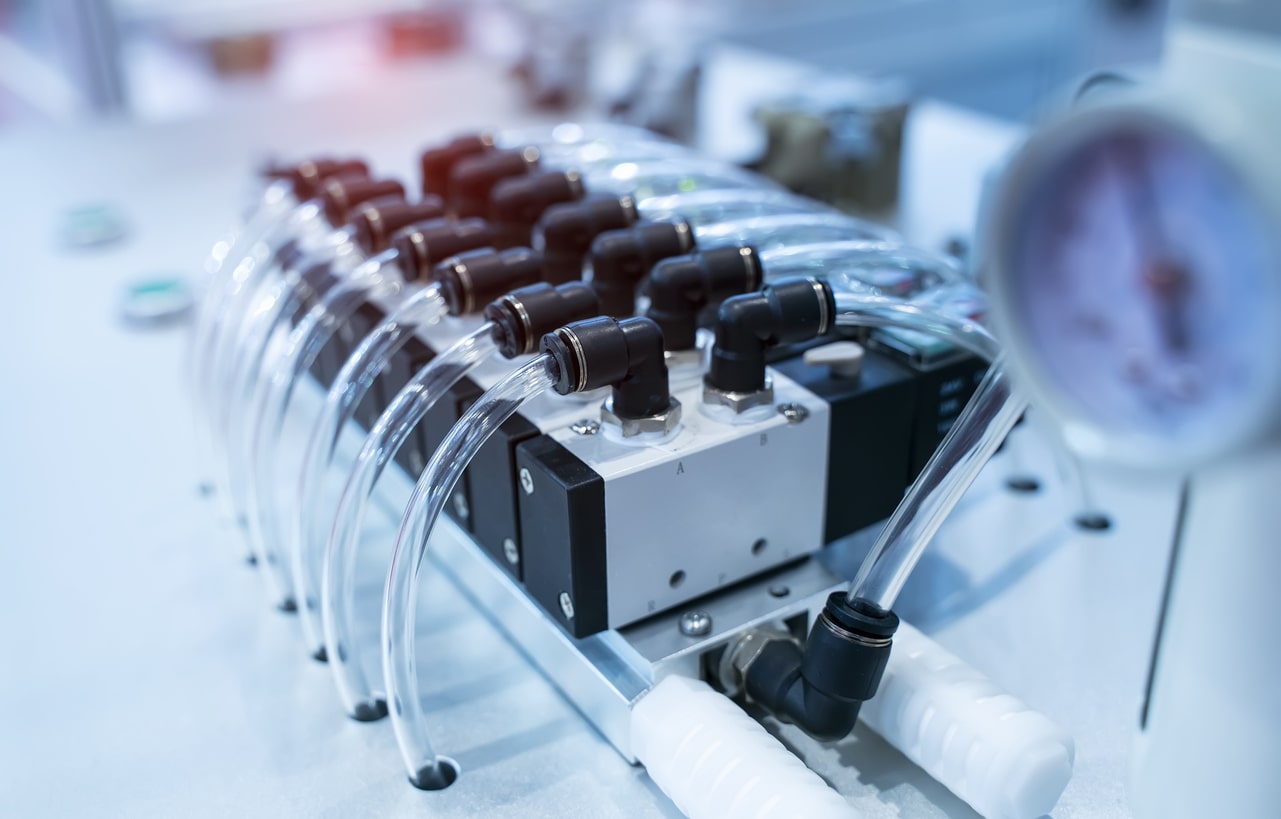

Pneumatic Fittings

Fittings are the connectors that join the tubing to different parts of the pneumatic system, such as valves, actuators, and tools. They ensure a secure and leak-proof connection. Similarly to tubing, fittings are made from a variety of materials, including brass, stainless steel, and plastic. There are various types of fittings, including:

- Push-to-Connect Fittings: Easy to use, allowing for quick connection and disconnection of tubes.

- Threaded Fittings: Provide a strong, tight seal and are available in various thread standards and sizes.

- Elbow and T Fittings: Used to change the direction of the tubing or split the flow to different channels.

Check out some of the fittings that RND provides below:

RND Plastic Push-In Connector Fitting

Features:

- One-Touch tube fittings are used in pneumatics piping.

- The tube fittings come in a wide variety of models to meet all your needs in pneumatics piping.

- Even after installation, the direction of the tube can be changed freely

- Ensures anti-corrosion and anti-contamination.

RND Brass X Fitting Female Thread

Features:

- Pneumatic fittings feature a quick-connect/disconnect mechanism, facilitating rapid assembly and disassembly of pneumatic systems.

- X-Fittings can withstand mechanical stress and pressure,making them reliable for use in plumbing, industrial equipment, or other situations where strength is crucial.

- They are available in various configurations, sizes, and thread types, allowing for compatibility with a wide range of systems and facilitating ease of installation in diverse settings.

RND Plastic T-Fitting

Features:

- One-Touch tube fittings are used in pneumatics piping.

- The tube fittings come in a wide variety of models to meet all your needs in pneumatics piping.

- Even after installation,the direction of the tube can be changed freely.

- Ensures anti-corrosion and anti-contamination.

RND offers multiple types of fittings for different pneumatic applications. Check out the whole range of fittings here.

How to Choose the Right Pneumatic Fittings for Your Application

For your pneumatic system to be safe, effective, and leak-free, you must select the appropriate pneumatic fittings. The following important factors should help you choose suitable fittings for your application:

- Type of fittings:

- Push-to-Connect fittings: Perfect for systems that need regular changes, these fittings allow for quick assembly and disassembly.

- Threaded fittings: Offer a more robust and long-lasting bond. Select the appropriate thread type for your system (NPT, BSPP, BSPT, etc.).

- T, elbow, and cross fittings: These are used to divide the air flow or alter the tubing’s direction. Make your selection based on your system’s layout specifications.

- Material compatibility:

- Plastic fittings: Ideal for low-pressure applications, lightweight, and corrosion-resistant.

- Metal fittings (Brass, Stainless Steel, etc.): Preferred for higher pressure systems, more durable, and can withstand harsh environments.

- Tubing size and type: The outer diameter, inner diameter, and material of the tubing that is being used must all match the fittings. A mismatch may cause leaks or the connection to break.

- Flow requirements: Ensure the fitting does not restrict airflow more than what your system can accommodate. The internal diameter of the fitting should support the required flow rate.

- Environmental factors: Take into account elements like UV radiation, moisture, chemical exposure, and extremely high or low temperatures. Choose materials that can withstand these circumstances.

- Ease of installation and maintenance: Consider how simple it is to install and maintain the fixtures. When reassembling systems that need to be disassembled and reassembled frequently, quick-connect fittings can save time and effort.

Why are Tubings and Fittings Important in Pneumatics Systems?

Airflow Management

In order to ensure optimal performance in pneumatic systems, efficient airflow management is essential. The diameter and length of the tubing have a big impact on how quickly and how much compressed air flows through it. Sufficient air delivery to run the system without needless pressure drop or energy loss is ensured by tubing of the proper size. Furthermore, precise control of airflow is made possible by the use of fittings such as elbows, tees, and valves, which direct airflow to particular areas of the system as needed. In applications like robotic arms or pneumatic tools, where precise movement or force is needed, this control is crucial.

Maintaining Pressure Integrity

In order to guarantee the safe and effective operation of pneumatic systems, pressure integrity must be maintained. Fittings and tubing must be able to sustain the maximum operating pressure of the system in order to avoid leaks, which can seriously impair performance. Small leaks can cause the compressor to work harder to maintain pressure, which can result in a loss of efficiency and higher energy consumption. Both tubing and fittings’ pressure ratings have to be at least as high as what the system requires. This is particularly important to take into account in high-pressure applications where there is a higher risk of failure.

System Connectivity

Pneumatic system connectivity depends on the use of different fittings, which allow different parts of the system to be integrated. Tubing can be connected to air compressors, valves, actuators, and tools using these fittings, which include couplers, elbows, and tees. They are made to offer a stable and secure connection, which is necessary for the pneumatic system to function dependably. Fittings’ adaptability to different thread types and sizes allows for system design flexibility. This flexibility is essential for ensuring that all the parts function together and for tailoring systems to particular applications. Furthermore, the simplicity of assembly and disassembly provided by some fittings, such as quick-connect models, greatly facilitates system modification and maintenance, improving overall effectiveness.

Why Choose RND’s Pneumatic Tubing and Fittings?

Distrelec’s own brand, RND, offers over 10,000 quality products. The brand provides highly reliable and compliant products that are of the highest quality. RND offers pneumatic tubing and fittings in a range of materials and sizes to suit whatever your application requires.