Of all the sectors that power supplies need to operate reliably in, anything requiring exposure to the elements must be the most demanding. Take railway transportation, for example. Parts of the electrical installation of an engine, passenger carriages, and freight trucks may be mounted externally and subject to ingress of water, oil, and many different types of dust particles. Even if mounted inside a carriage, they can still experience shock and severe vibrations daily. Then there are the electrical conditions that frequently involve large voltage swings, momentary loss of power, and powerful transients.

This article investigates some of the operational challenges that railway applications experience and why understanding the technical considerations are a must before selecting suitable power supplies.

Provisioning reliable power in the challenging railway environment

From a passenger’s perspective, most modern railway carriages are comfortable, well-lit, and equipped with modern technology. Seating typically offers mains power outlets and USB power. Information displays indicate progress along the journey and the likelihood of delays. Behind the scenes, public Wi-Fi, carriage heating and ventilation systems, and online infotainment systems occupy passengers and make the trip enjoyable. Safety features such as smoke detectors and security CCTV are omnipresent. Door controls, door openers, and emergency lighting all are based around electronic systems today, and as everything else highlighted, they all require power. Moreover, electronics-based systems and associated power supplies are susceptible to voltage variations, interruptions, and environmental conditions.

Power is probably something we all take for granted in our homes and offices. Power outages are typically uncommon, and access to a reliable and stable main power supply becomes the norm. However, for railway and other transportation applications, the stability and reliability of the power supply is not as assured.

Understanding the electrical and environmental challenges of railway applications

The electricity available on a train comes from a generator attached to the main engine or via an overhead pantograph. Both are subject to voltage spikes, surges, and drop-outs—some of these result from the myriad of electrical and electromechanical equipment used for rolling stock systems, such as braking. Momentary interruptions of supply also occur.

Another significant aspect of a railway application is the environmental operating conditions. Some systems are mounted externally, subject to weather extremes, rain, snow, ice, and the associated temperature swings. Dust, particularly with conductive elements, are a particular hazard. Even inside the passenger carriage, condensation occurs regularly. Then there are the many jolts, vibrations, and rapid motion forces we all experience.

When selecting a power supply for a railway application, let’s investigate several vital considerations, starting with the supply voltage.

Railway Voltage Sources

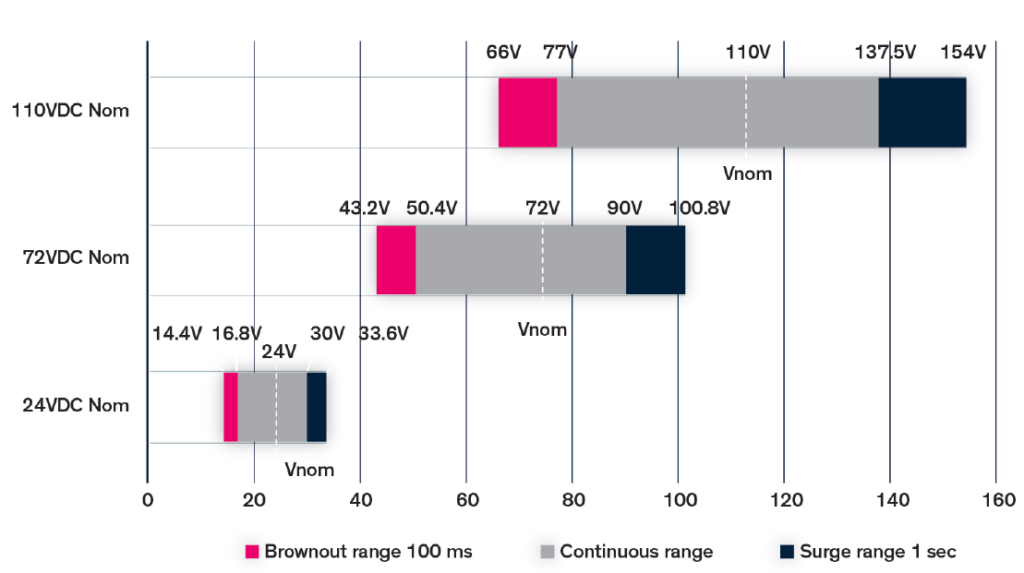

Most railway supplies for electronics-based equipment are DC, emphasising the application using DC/DC converters. As already highlighted, the supply in electrical terminology is noisy. Over the evolution of railway electrical systems, standards have emerged that provide a relatively well-defined specification under which a power supply should operate. EN 50155:2017 is the principal standard covering most equipment for voltage, environmental and safety characteristics. The standard stipulates several nominal working voltages (Vnom), three of which are illustrated in Figure 1. The continuous operating voltage range is coloured grey, and the ‘brown out’ voltage, essentially a short-term sag or drop of the input voltage for 100 ms in red. The black bar defines a surge voltage range.

Any DC/DC converter selected for a railway application must comply with EN 50155, and consequently, many suitable converters can accommodate an input voltage range of at least 4:1. For example, based on a 24 VDC nominal, the input voltage range is 9 VDC to 36 VDC. Outside these specifications, additional hold-up capacitors provide a brief period of continued operation and need to survive surges. To an extent, surge voltages can be suppressed with active clamps, although the energy involved can be substantial. Railway standard, RIA12, requires extended immunity to surges of voltages up to 8.5 kV of 100 ns duration.

Electromagnetic Immunity (EMI), Electromagnetic Compatibility (EMC), and Electrostatic Discharge (ESD)

Short nanosecond duration, high voltage transients (high dV/dt) of thousands of volts can easily damage or disrupt the operation of sensitive electronic systems. Such transients can be radiated electromagnetically or conducted through power supply rails. The function of a power supply should cause problems or interfere with other equipment. Likewise, a power supply must be immune to any emissions from other electromagnetic sources.

EMC relates to whether, for example, a DC/DC converter creates any electromagnetic emissions, and standards, EN 61000-4 (radiated) and EN 50121-3-2 (conducted) apply.

EN 61000-4 also covers electromagnetic immunity to radiated and conducted emissions, surges, fast high voltage transients, and electrostatic discharge.

Shock, Vibration and Environmental considerations

Shock and vibration are perhaps the most significant mechanical forces to which a DC/DC converter is exposed. Standard EN 61373 stipulates various categories depending on the mounting location. The minor forces are experienced on or in the rolling stock body, whereas mounting on an axle assembly is the most severe.

Environmental standards such as temperature and humidity are detailed by EN 50155, categorised according to the mounting location, either in an internal cubicle or externally. The impact of sudden temperature shock between significantly different temperatures that can potentially result in condensation is another requirement of this standard.

For passenger safety reasons, DC/DC converters used in railway applications must also comply with EN 45545-2. This standard defines the materials used for the construction of the converter, whether it might start a fire, and its usage.

Selecting suitable power supplies for railway applications

Traco Power manufacturers a range of DC/DC converters certified for use in railway applications. Figure 2 highlights Traco’s portfolio of DC/DC converters for a variety of use cases.

For example, the THN series of encapsulated metal cased 20 Watt DC/DC converters suit use in climate control systems and offer a high conversion efficiency, typically 91 %, and accommodate a 4:1 input voltage range. See Figure 3. This board mounted converter, measuring just 2.54 cm x 2.54 cm, has input to output isolation is 3 kV and conforms with EN 50155, EN 61373, and EN 45545-2 standards.

Suiting the requirements of higher loads, such as external displays, the TEQ series, see Figure 4, provides up to 300 Watts and 900 Watts by combining three converters in a power-sharing arrangement. This high power density, convection cooled converter is packaged in a rugged sealed metal case with heatsinking fins.

With an exceptionally high, ultra-wide 12:1 input voltage range, the TEP 40UIR series of 40 Watt is housed in an industry-standard, quarter-brick metal package. Typical applications include brake control and switch/signal control applications. The TEP 40 UIR series comprises two input voltage variants based on 36 VDC or 110 VDC nominal inputs. Both versions offer the popular nominal output voltage of 5 VDC, 12 VDC, 15 VDC, 24 VDC, and 48 VDC.

For railway applications requiring compact, fully regulated, and isolated low power DC/DC converters, the TMR 6WIR series of 6 Watt provides an ideal solution. The board mounted series uses a SIP-8 metal case construction format to occupy minimal PCB area. A typical railway use case is for door control systems.

Another compact DC/DC converter in an industry-standard 1-inch x 2-inch form factor in a low-profile metal case is the 20 Watt TEN 20WIN series. On-board communication systems are typical applications for this series.

Providing compliance to the RIA12 surge standard is the TFI 300, a 300 Watt surge filter – see Figure 5. Placed in front of a DC/DC converter, the TFI protects the converter from damage by actively clamping its input voltage exceeding 168 VDC. The filter complies with the higher specification of RIA12 that allows transients of 20 ms at 385 VDC.

Railway applications demand reliable and rugged power supplies

When it comes to operating DC-powered equipment in demand environments, railway applications are high on the list. This article highlights some of the essential factors that engineers should carefully review when selecting suitable products. Compliance with specific railway standards covering voltage supply rails, EMI, EMC & ESD, and environmental operating conditions are mandatory.

Distrelec is an authorised distributor of railway approved DC/DC converter products from Traco Power.