Operational technology (OT) and information technology (IT) convergence represents a transformation in the ever-changing field of industrial automation. The Industrial Internet of Things (IIoT), also known as Industry 4.0, is centred around this merging, which presents new possibilities and difficulties for industrial networking and connectivity.

Navigating the complexity of OT and IT integration while choosing the best industrial connectivity or networking solution for an IIoT project might be difficult. Luckily, there are brands like Moxa that allow you to find the best networking solutions to connect your industrial devices and systems with ease. Moxa has been providing industrial networking products and solutions for over three decades.

With a dedicated focus on industrial connectivity, Moxa has been a pioneer in developing solutions that are designed to meet the challenges of IIoT. Whether you work as an IT or AI engineer, an OT or IT system integrator, a plant owner, or a system operator, the purpose of this article is to make it easier to understand the complexity of industrial connectivity and help you find the best industrial automation products.

How to Enable IIoT Connectivity?

OT and IT have historically functioned in distinct domains. Whereas IT concentrated on data processing and network architecture, OT was involved with the direct management and monitoring of physical devices. But these two worlds are merging with IIoT. Real-time data gathering and analysis are made possible by this integration, which boosts productivity, decreases downtime, and improves decision-making.

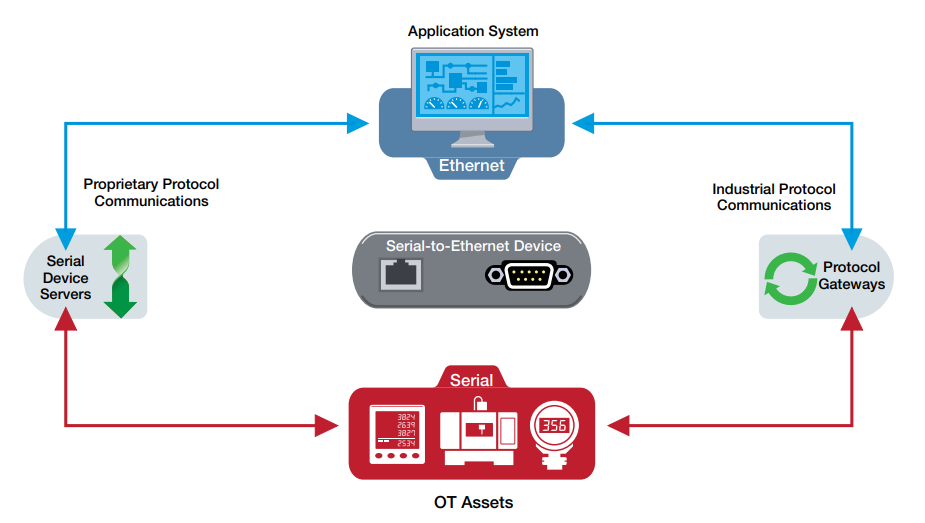

To implement IIoT applications it is important to connect the previously disconnected industrial field equipment and assets. Understanding the OT assets that must be linked and their unique connectivity needs—such as connecting to local networks or cloud servers—is essential to this process. The majority of OT assets in industrial settings are serial or I/O interface-based, thus selecting the right serial and I/O connectivity solutions is essential. There are additional factors to consider when connecting OT assets to cloud or remote servers.

Challenges of IIoT Connectivity

In an IIoT framework, selecting the appropriate connectivity options requires overcoming certain challenges. Systems that are strong and dependable are necessary for industrial settings in order to provide smooth data transfer even in harsh environments. The main challenge is to ensure that the data is reliable, and that the system is not affected by external factors, such as power outages, network interruptions, or any other type of interference. The choice of the right connectivity solution is essential for guaranteeing the reliability of the data. Hence in the next section we will discuss the various connectivity options available with examples from Moxa.

Challenges in Selecting Industrial Connectivity Solutions

The combination of IT and OT creates new difficulties when choosing the right networking options. Systems that can resist extreme circumstances and guarantee seamless data transfer and interoperability are essential in industrial environments.

1. Serial Device Servers

When it comes to updating outdated systems, serial device servers are essential. With their help, outdated equipment can connect to contemporary network infrastructures via serial-to-Ethernet communication. It also makes it easier for the gear to be integrated into IIoT frameworks and increases its lifespan.

Since 1987, Moxa has dedicated itself to offering dependable industrial solutions for device communication. The company boasts a portfolio of more than 500 serial/USB connectivity products, featuring solutions with industry-specific certifications for rail applications, power automation, intelligent transportation systems, harsh environments, and more, positioning Moxa as a global leader in the field.

2. Protocol Gateways

Protocol gateways, which are referred to as industrial fieldbus protocols, offer special advantages for various system applications that are necessary to provide smooth connection between various industrial systems and devices. They serve as translators, facilitating efficient communication between devices that employ various communication protocols. For an industrial network to be coherent and effective, interoperability is essential.

In addition to connecting your serial devices to an Ethernet network, Moxa’s proprietary fieldbus-to-Ethernet MGate gateways support multiple connections and protocol conversion between EtherNet/IP and Modbus TCP.

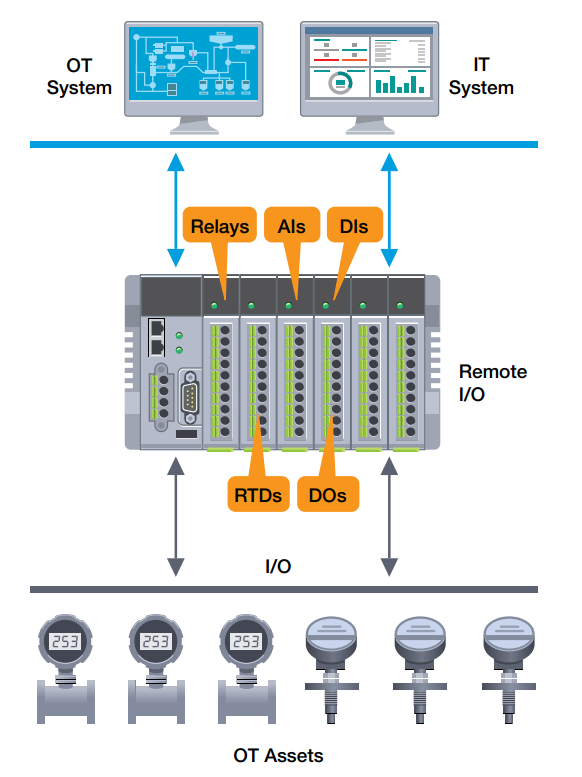

3. Modular Remote I/O Solutions

Traditional data collecting techniques are challenged by the growing complexity of IIoT systems. For IIoT applications, modular remote I/O systems provide scalability and flexibility. They make it simple to include different sensors and actuators into the network, facilitating more thorough data collection and control throughout the industrial process.

Typically, field sites are equipped with remote I/O devices, which provide data access and environmental monitoring from a remote control centre. I/O data capture guarantees that field application runs smoothly every day, maximising production.

From installation to operation to maintenance, choosing a modular remote I/O solution is essential for making the most of the data that has been gathered. When using data, it’s critical to make sure that both OT and IT systems are compatible. To protect gathered data, it is also crucial to integrate or support cybersecurity capabilities.

Cybersecurity in Industrial Networks

Cybersecurity is becoming an important concern in the IIoT era as industrial networks become more integrated. Therefore, it is critical to defend these networks from cyberattacks since compromises might result in serious operational disruptions and safety hazards.

Industrial system security requires the implementation of strong security mechanisms and ongoing network activity monitoring. It means that industrial applications require connecting more field equipment to public networks so that field data can be accessed by IT and OT experts. While there are many advantages to making field equipment more accessible to the outside world, doing so also increases the security dangers to the networks. Proper protection is key to ensuring the safety of your industrial network.

Find out more about cybersecurity and industrial security in the age of digitalisation here or go to Moxa’s Industrial Cybersecurity Solutions site to learn more about industrial cybersecurity and how to protect your industrial network.

Future-Proofing Industrial Networks

The rapid advancement of technology in the IIoT domain demands that industrial networks be future-proofed. This entails implementing scalable, adaptable systems that can take into account new needs and developing technology. It is essential to maintain compatibility with upcoming standards and technologies in order to be competitive and efficient.

Shifting Into IIoT

The industrial sector’s convergence of OT and IT is more than just a trend; it’s a paradigm shift that changes the rules for how industrial operations are carried out. Businesses must embrace this shift and choose the appropriate networking and connectivity solutions if they are to prosper in the IIoT era. In order to promote innovation and efficiency in industrial processes going forward, it will be essential to integrate cutting-edge technologies and place a high priority on cybersecurity.

Distrelec, a supplying partner of Moxa, sells edge connectivity products, including the above-mentioned NPort, IO, and MGate as well as Media converters, UPorts and more. Click on the link below to see the full range of Moxa’s industrial connectivity products.