If an industrial manufacturing plant wants to succeed, it must consider investments in automation and interconnectivity. The result is an increase in productivity output, minimising the overall costs of ownership, ensuring maximum safety in the workplace, optimising the logistics and ensuring accurate real-time decisions are made based on captured data.

There’s no way to avoid industry 4.0.

While manufacturing was already heading in this direction before 2020, COVID-19 accelerated the journey. It also revealed how vulnerable plants could be when they aren’t ready to scale and digitise to maintain operations and handle surges.

For companies already on a journey to digital transformation, the sudden adjustment due to the pandemic was not as harsh, and the change only confirmed that they were indeed on the right path for the future.

The writing was on the wall for industrial sites that weren’t yet taking advantage of automation: the difference is here, and it’s here to stay.

This drive toward automation, Industry 4.0 and the Industrial Internet of Things (IIoT) is also driving demand for industrial Ethernet cables that withstand harsh environments such as noise, vibration, abrasion, repetitive motion and environmental conditions.

There are four key factors to consider when it comes to the total cost of ownership for industrial-grade cables.

1. The initial cost of the system

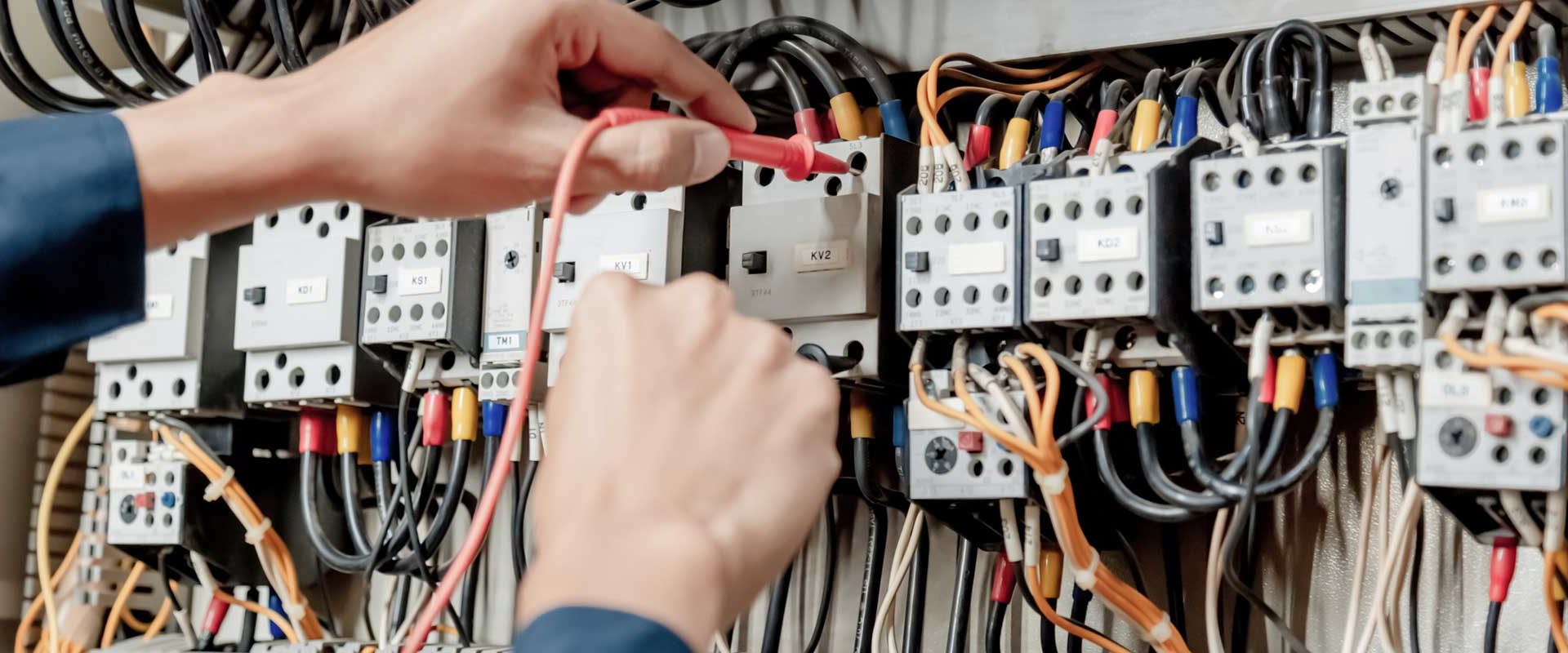

Every company ultimately wants to reduce costs and save money where possible, and why wouldn’t you want to do that? Sometimes, however, some cost-cutting techniques could be made in the wrong places and have a detrimental impact. For example, the expenses associated with implementing a control cabinet (I/O blocks, switches, PLCs and sensors). The cabling costs are typically less than 2% of the overall systems price.

Attempting to reduce your investment by inexpensive sourcing cables minimises savings whilst also creating a very high risk of equipment failure resulting in machine downtime.

As you may know, cables are exposed to everything in industrial environments, from oil and vibration to dust and high temperatures. Cables must be able to withstand these conditions and perform consistently 24/7. The initial investment in a rugged, industrial-grade line is the only way to ensure long-term reliability and reduce downtime, resulting in overall cost savings.

Belden cables conform to IEC 60811-2-1 (Oil resistance) and have a temperature rating between -40 to 80c, as well as offering flame resistance under UL AWM 21292.

More recently, a wastewater plant in the US was having issues with its outdoor cameras for the monitoring treatments process. When using a regular Ethernet cable between the cameras and control unit, the images broke up. A move to switch to Belden’s industrial Ethernet cables, which features Bonded-Pair-Cable construction, soon fixed the problem without the need to replace any expensive equipment in the process.

The bottom line: The cable isn’t the place to reduce overall system costs. Select a cable with additional headroom to accommodate future performance requirements if you want to make the most of your initial cable investment. For example, even if your current application calls for a Category 6 cable, choose a Category 6A solution to make sure you’re ready to add devices down the road without creating bandwidth constraints or, worse, replace the entire cable system to support new additions.

2. The Cost of Maintaining Equipment

When a wired network goes down, the physical layer—a loose connection, damaged cable or poor-quality connector is usually the culprit most of the time.

Even though a generic off-the-shelf Ethernet cable may work for a little while in a manufacturing or industrial environment, the line will most likely fail over time. Unlike industrial-grade cables, commercial Ethernet cables are not exposed to harsh conditions such as cold bending, abrasion, high temperature, oil or EMI/RF interference when testing their performance. They are never intended for use in these applications other than office use.

Due to the nature of generic cables, you will need to replace them over time and time after that. This will result in no cost-saving over time with the costs of the cables and the downtime of any equipment.

The more time you spend fixing the issues, they create after installing them, the more money you spend over the long term.

3. Unplanned machine downtime could be very costly

Any downtime would severely impact any company that mass produces any product or goods on the production line. Every idle time in seconds translated to lost revenue and unmet targets with critical customers.

A 2020 downtime survey led by ITIC indicates that 40% of enterprise organisations lose between $1 million and $5 million per hour. This loss could equal $500,000 or more for every hour of downtime, depending on the business.

When these companies see their money slipping away, there is usually an initial panic or scramble to troubleshoot the issue, either hiring a costly consultant or on-site engineer.

Depending on the problem identified, the repair cost and parts availability could last from a few minutes to a few days.

In some cases, it’s not cost-effective to restart production lines if they shut down suddenly. Instead, the lines must be rebuilt, which leads to significant losses.

Some customers have learned this lesson the hard way. One of Belden’s customers had unexpectedly shut down their plant for six hours.

The cause of the issue was simply a poorly terminated RJ45 connector. Any measure that could be prevented during the planning phase to avoid unplanned downtime must be taken, including the investment in quality cabling solutions, which will pay for themselves over time.

4. The Hidden Cost of Non-Compliance

Often compliance can be an area that is overlooked or turned a blind eye to. Standards exist for many reasons; they ensure safety requirements are adhered to within the workplace.

These standards define cabling types, recommended operating conditions, interconnectivity, performance parameters, testing requirements and more. Standards give us a common language to ensure quality and safety criteria are met that guarantee a minimum level of performance when in use.

An excellent example of this is standards that dictate that outdoor applications use a cable rated for the purpose. It is not essential to do this, but you will not get the expected results with a rated line. Overall performance would be hampered.

Summary

There is no doubt that poor planning and use of low-quality cabling solutions would, in the long term, drive high costs for most industrial applications. The initial investment phase of the projects must ensure all aspects of automation solutions be invested in with the commitment to provide any machine downtime be kept to a minimum and unplanned maintenance avoided. Belden cable solutions are a trusted brand that delivers results for its customers year on year.