Select your product, add to basket, pay, and wait for your parcel to arrive. For the customer the process is simple. However, behind the scenes, the logistical task of getting goods to the door or store since the advent of e-commerce is infinitely more complex. The overriding question in the boardrooms of logistics companies has been: how can we do things faster and more efficiently without compromising quality of service? Now they’ve found the answer: smart machines, and more interestingly, robots.

This article explores the impact that robotics can have at every stage of the supply-chain, from warehousing down to end-delivery. According to a report by Statista, the logistics sector purchased 158,000 logistics robots in 2021, with the number set to rise to 250,000 in 2023. The warehouse robotics market is expected to grow from $6.1 billion in 2023 to $10.5 billion by 2028, at a compound annual growth rate (CAGR) of 11.4%. But why are robots so in demand, and how are they revolutionising the logistics sector?

How are Robots Revolutionising Logistics?

Warehousing

The term “warehouse robotics” refers to the employment of robots, automated systems, and specialised software to carry out various jobs like transporting materials, and speeding up repetitive warehouse operations.

Types of warehouse robots

A variety of warehouse robots, including automated guided vehicles (AGVs), automated collaborative robots or ‘cobots’, and robotic arms, are currently available on the market. All of these robots speed up, streamline, and ensure accuracy in the warehousing process. The robots in the warehouse can pick up and move objects, close and seal boxes, and assist with inventory. Some of the most common robots in the warehouse are as follows:

- Automated guided vehicles (AGVs) – in warehouse settings, automated guided vehicles assist in moving inventory, commodities, and supplies – but they rely on predefined paths. In operations, AGVs are used to replace manually operated forklifts or pick carts. Some AGVs employ physical guides such as wires, magnetic strips, tracks, sensors planted in the floor, or other physical markers to designate predetermined routes through warehouse facilities. Other AGVs navigate work environments, detect obstacles, and avoid collisions by using cameras, lidar, infrared, and other cutting-edge technologies.

- Robotic arms – Multi-jointed limbs known as articulated robotic arms are used to manipulate products in warehouses and distribution centres. They are a sort of pick-and-place robot which can be used for picking, packing and storing parcels, and palletising.

- Automated storage and retrieval systems (AS/RS) – A collection of computer-controlled systems which are used to automate inventory management and store/retrieve products as needed. These technologies are typically used in conjunction with warehouse execution software and are intended to speed up product retrieval and placement.

- Goods-to-person – As with an AS/RS system, goods-to-person (G2P) technology works on the same tenet. G2P technology makes use of an automated storage system to transport goods to fixed pick stations where workers process orders.

Cobots

Cobots are a type of robot which are designed to work harmoniously with humans to assist with repetitive tasks. Cobots have shown to be advantageous for both manufacturing and distribution operations since they are secure, adaptable, quick to implement, and simple to programme. They are gaining significant popularity and are being introduced into more and more warehouse tasks.

In May 2023, Universal Robots showcased the world’s first cobot spot welder at Automate 2023 – a task that cobots were previously unable to carry out, due to the weight of the welding gun and difficulty of the welds. Meanwhile, Opel’s Eisenach automotive plant recently implemented cobots to drive screws in engine assembly. The business was able to relieve its workers of a physically demanding duty that could have otherwise resulted in long-term health problems and lost productivity.

What jobs can robots help with in the warehouse?

Packing and unpacking

Robotics has the potential to dramatically increase productivity in the logistics sector, especially when it comes to box packing and unpacking. Robots can considerably increase the speed and accuracy of box packing and unpacking by automating these activities, which could result in significant cost savings for logistics organisations.

Robots can also make the cargo packaging process safer, as they can facilitate the movement of big objects inside warehouses and also work in areas which would be hazardous for humans. Another benefit of implementing robotics in this area is that it reduces the chance of human error.

An example of warehouse robots streamlining packing processes can be seen in Brightpick’s efficient solution for automated order fulfilment below, which can be used for various products like groceries, pharmaceuticals, electronics, and personal care products.

Maintenance

Automation of equipment maintenance is possible in the logistics and freight sectors thanks to robotics. By using machine learning technologies such as machine monitoring you can decrease equipment downtime by examining machinery, analysing performance using sensors and detecting issues before they arise, saving the company in time and money. If you want to know more about how AI can be used in maintenance, check out our article.

Stock monitoring

By automating the inventory management process, businesses can ensure that they’re never short on stock. Robots with sensors can monitor stock levels and report back to a central database with their findings, eliminating any risk of human error. Then businesses can act accordingly, replenishing stock levels and continuing normal trade without any delays for the customer.

Package tracking

There are many benefits of adopting robotic technologies to track packages. As shipments move through the supply chain, robots can first rapidly and precisely scan them and track them in real time. The route can then be optimised using this information to guarantee on-time delivery of the cargo.

Transportation

Over the next decade, the transportation of goods will be influenced by AI and automation technologies, in order to speed up the process and make it more efficient. Lots of industries will introduce innovative technologies in an attempt to deliver the best services.

Shipping

The first completely autonomous, zero-emission container ship set sail from Norway in 2022, beginning a two-year trial. Yara and KONGSBERG launched the Yara Birkeland as a joint venture. The ship’s 7 MWH battery has 1,000 times the energy storage capacity of a standard electric car battery. While the largest ships currently at sea can carry 24,000 containers and travel twice as fast as the Yara Birkeland, the ship can only transport 120 containers at an average speed of 10 knots. Other features like route optimisation, predictive maintenance and data collection are greatly enhanced by AI in shipping.

Rail freight

A self-driving robot which travels around and inspects the state of railway tracks was trialled in 2022 by Chalmers. Its aim is to detect any issues as early as possible to lower maintenance costs and reduce any delays. The robot can run on tracks without any human assistance thanks to cameras, 3D lidar, GPS, an accelerometer, and lots of training data. It slows down whilst meeting other trains and can also read signs and signals.

“Today, the problems on the railway tracks are often fixed only after they have occurred, and it becomes expensive for society to close sections for long periods of time. With the help of this robot, problems can be quickly detected and fixed before an accident or derailment occurs, while increasing accessibility for travellers and cargo traffic and saving money for society. In addition, safety is increased for those who work with railway maintenance” – Krister Wolff, Docent at Chalmers.

Autonomous trucks

Industry experts are predicting that driverless trucks will be a common sight on roads in the next ten years. The integration of autonomous trucks will improve logistics and supply chain management. Delivery times are more predictable with more automation, improving overall efficiency. The potential for just-in-time delivery and simplified procedures is made possible by this increased efficiency.

One of the challenges that autonomous vehicles face is understanding their environment and acting accordingly. For changing lanes, cars usually need a few seconds, but for trucks this manoeuvre typically takes about 7-8 seconds. TuSimple has devised a technology where the truck will get a bird’s eye view of its environment, helping it to understand its vicinity better. Special cameras are installed around the vehicle and a detailed 3D visualisation of their environment is created by cross-referencing spatial data and 2D object tracking and detection.

End-delivery

The final step on the supply-chain isn’t being disregarded. Companies around the world are developing technologies which can help to streamline end-delivery.

Automated Mobile Robots (AMRs)

Europe’s first fleet of delivery robots to operate on public roads was launched in Lithuania in June 2023. The deployment is the result of a partnership between autonomous vehicle manufacturer Clevon, delivery transportation platform LastMile and supermarket chain IKI. The autonomous robot carriers (ARC) pick goods up from the supermarket and deliver to customers’ homes. The customer can unlock the ARC with a code which is sent to their mobile phone.

In the UK, parcel delivery service DPD is expanding its autonomous robot deliveries to 10 UK cities and towns over 2023. The robots navigate on footpaths using just a camera, whilst the customer can locate the robot on a map on their mobile phone. Meanwhile, Estonian company Starship – the first company to launch the autonomous mobile robot for deliveries in a British town centre – completed its 5 millionth autonomous delivery in May 2023. With significant uptake in a range of industries, it’s no surprise that the AMR market is set to see significant growth by 2030, with a CAGR of 15.5%.

Delivery Drones

It’s not only the streets in our cities that are seeing innovation in end-delivery, though. As per Forbes, restaurants can cut the average cost of delivery by as much as 40% by implementing automated, end-to-end drone delivery. As well as transporting goods, drones are an effective way of delivering medicines to customers. American company Zipline has been delivering life-saving blood and medical supplies to 12 regional hospitals in Rwanda which are in remote locations, and is now working with other countries in the continent.

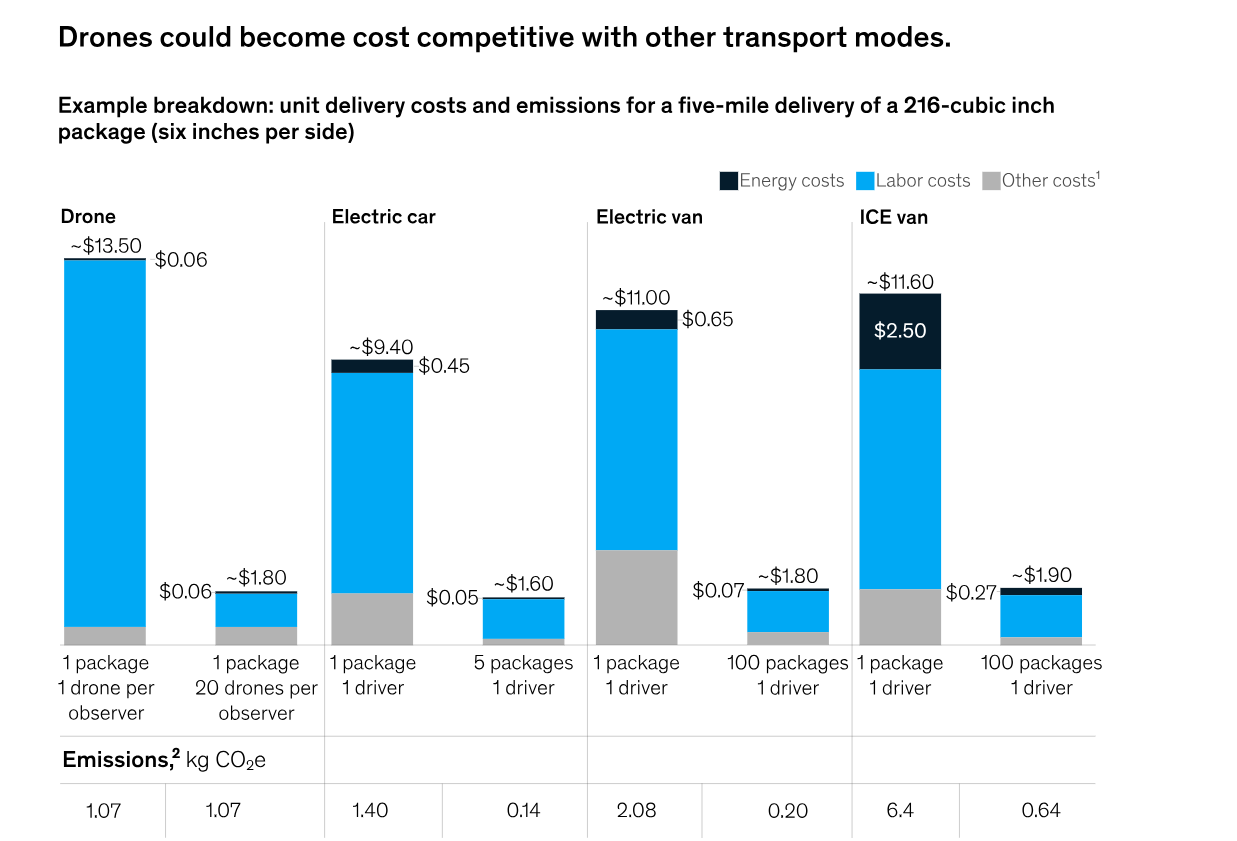

According to McKinsey & Company, delivery drones could become as cost-effective for package delivery as traditional transport methods. In some regions where travel infrastructure is poor, drones may already be the most cost-efficient mode of delivery, whilst also being a lot greener than using trucks.

What can we expect in the future?

Given that customer expectations and the volume of packages, shipments, and orders have risen to levels that are unmanageable for conventional methods, autonomous robotics has the potential to enhance operations and offer new opportunities to increase productivity, decrease risk, decrease cost, and improve data collection. Companies are constantly seeking ways to stay ahead of the curve, and it’s clear to see that improvements can still be made at every step of the supply chain. As we speak, a variety of new innovations are being trialled and implemented to improve operations in the logistics industry.

With all this technological development, there may be the lurking fear that robots will take our jobs, but that shouldn’t be the case. Humans are already working collaboratively with robots in an efficient way, but there is room to scale this up to optimise the entire process. We shouldn’t fear robots taking our jobs, but instead embrace the added value that robotic systems bring. The future of humans and robots working side-by-side is an exciting thought.