The humble control cabinet is a stalwart of any industrial machinery installation. Initially used to house a few relays, fuses, switchgear, and simple controllers, cabinets are experiencing transformational changes. With the advent of the industrial internet of things (IIoT), Industry 4.0, and other operational effectiveness improvements, control cabinets are the go-to locations to place all the new automation components and systems within. However, the amount of machinery space required goes beyond that available. With factory floor space at a premium, this opens the door to several technological advancements to cope with immense pressure on squeezing more industrial control devices into a fixed cabinet space. This article highlights why a more strategic approach to control cabinet use is needed.

The changing world of industrial control

Modern factories and manufacturing processes are becoming increasingly automated and heavily optimised. Operational technology (OT) is at the very heart of these improvements. Production processes routinely use vision processing systems to detect, for example, the correct alignment of labels on bottles and whether the enclosure is correctly fitted. Real-time vision processing and machine learning neural networks enable high throughput rates and increased asset utilisation. Robots and collaborative robot usage are also commonplace, increasing the technology needing deployment within the manufacturing environment.

Factory floor space; a scarce resource

While the operational efficiency improvements of IIoT and OT can yield significant benefits, it creates a few implementation challenges for plant management. Factory floor space is always at a premium, with the priority placed on accommodating production assets. However, what about where to place the control equipment? In the past, each item of machinery was typically allocated space for a single control cabinet. IIoT installations depend highly on electronic systems, sensors, and actuators to operate efficiently. Cabinet and control panel designers now find themselves accommodating vision and image processing, predictive maintenance systems, networking switches, and power supplies. Automation highlights the need for compliance against functional safety standards like IEC61508 and IEC62061. Adherence to electrical safety, electromagnetic compatibility (EMC), and electromagnetic immunity (EMI) regulations also require close attention. Don’t forget power conversion modules, motor drives, process logic controllers, and electrical switchgear; they all need accommodating.

As industrial automation technology advances, production management can embrace new concepts and market trends. A recent trend currently gathering momentum and following on from Industry 4.0 and the IIoT is digital twins. Essentially, digital twins are a replica of a physical production line. In addition to a twin’s use for monitoring plant performance, they provide a digital platform for simulating and modelling different production techniques and scenarios.

Yet more technology places further pressure on the cabinet and panel space, escalating the need for a structured approach to optimise the available space.

Control cabinet challenges

What needs to be inside the cabinet or panel?

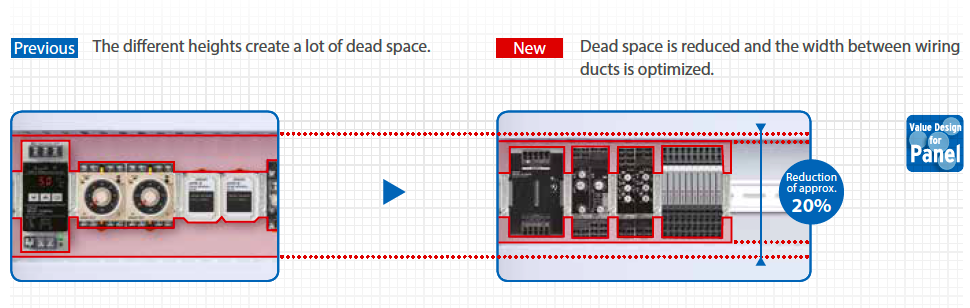

For industrial system architects, attempting to find space for another item of control equipment is only the first challenge. Designing a new panel requires the builder to carefully review the types and numbers of devices to be included. Is there a logical grouping to them regarding their function or physical size? What about the connectivity to other modules and controllers? Perhaps locating specific parts adjacent to each other is beneficial for reducing cabling complexity. Also, grouping devices of the same height profile together helps optimise the available space.

Avoiding thermal management problems

While making a list of the controllers, modules, and devices, take note of the manufacturer’s recommended minimum spacing distances, if quoted. A key reason for this factor is thermal management since heat dissipation becomes key within a tightly packed cabinet. Some units may generate more heat than others; power supplies, for example, might yield a few watts of heat even if they are highly efficient. Several items producing small amounts of heat may create a hot spot within the cabinet, potentially impacting other equipment items.

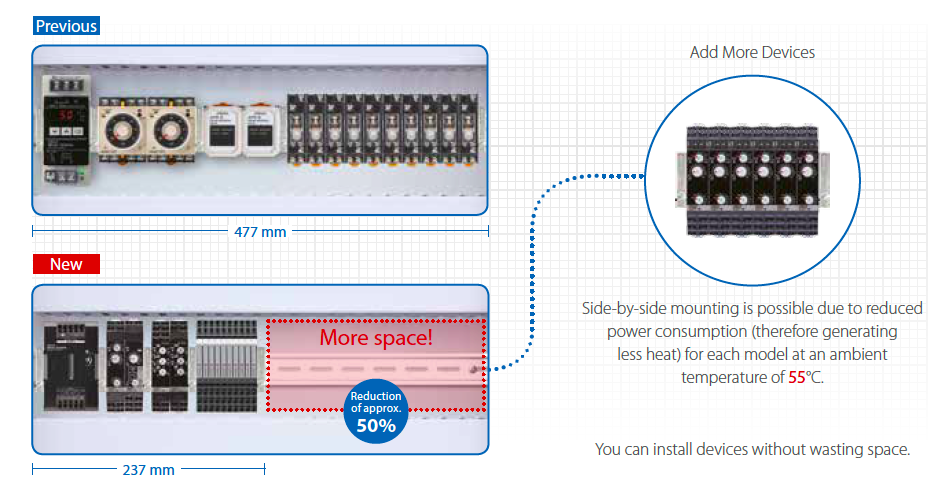

Some control cabinets may require forced air cooling, putting further constraints on the available space. Selecting control units specifically designed to minimise the amount of waste heat radiated and suitable for dense side by side mounting improves space utilisation.

Cable management; avoid cable confusion

Adequate attention to addressing cable management challenges may be overlooked during installation. Cable accessibility, identification and routing are critical factors over the lifecycle of the production asset. Clear cable identification and convenient fixing methods will ensure maintenance tasks go smoothly and quickly. Also, depending on the cable diameter and type, minimum cable bending radiuses must be carefully considered, which is particularly important for optical cables. Routing low voltage unshielded signal cables from an analogue sensor alongside high power cables, motor drives, for example, may result in high voltage transients becoming induced on the sensor inputs, resulting in erratic system behaviour.

The recent rise in the popularity of push-in cable terminations helps speed cabling during installation. Spring-loaded connectors provide a convenient, tool-free and reliable connection for solid conductors or pre-assembled cables with ferrules. Insertion forces are minimised, reducing cable stress, yet maximising retention and pull-out avoidance.

Standards compliance; electrical and functional safety

Equipment designed for the industrial domain must comply with relevant safety standards. This requirement protects workers and production machinery from harm. Internationally recognised standards stipulate safe separation distances for high voltage terminals, maximum leakage currents, and minimum electrical isolation voltages. For electrical circuits used in potentially proximity to explosive or flammable substances, intrinsic protection regulations apply.

Functional safety risk assessments and standards define the likelihood and severity of accidents occurring due to equipment malfunction. These safety standards apply to a system as a whole, including software. Semiconductor devices used in industrial automation systems increasingly feature functional safety features. Examples of electromechanical protection devices include force guided relays.

Electromagnetic conformance and immunity (EMC/EMI)

The industrial domain is electrically noisy. High-frequency inverters, fast switching motor drives, and high power motors all conspire to create an environment that dictates using equipment that meets relevant EMC & EMI standards. Standards such as IEC61000 and the EMC Directive 2014/30/EU also recommend minimum separation distance between network cables and power conductors. System architects and cabinet designers are advised to check the manufacturer product information and datasheets for compliance.

The future of industrial control cabinet and panel design

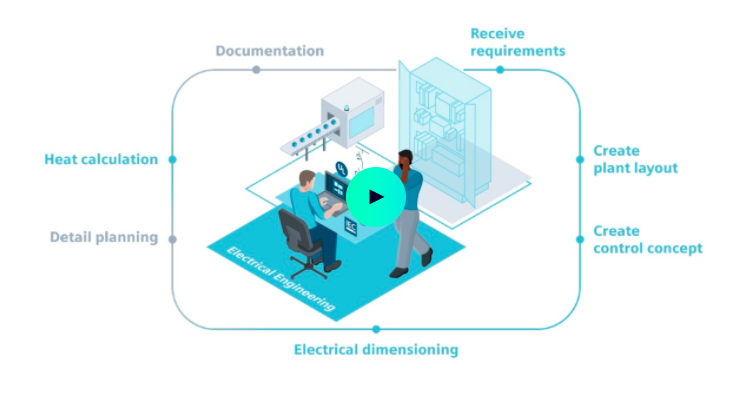

With many layout and design considerations, the panel builder’s task is daunting. However, control cabinet suppliers now provide a comprehensive set of 3D planning tools and configurators and digital systems that ease the complexities of panel design. 3D design resources, including 3D models of the many devices and systems placed in the cabinet, allow the systems architect to visualise different layout alternatives before selecting the optimum arrangement quickly. Once a configuration is selected, the design application can model the thermal profile and electrical dimensioning. Architects can compile necessary documentation and standards compliance certifications with ease too. Figure 1 illustrates an example process using the Siemens Control Panel Design workflow.

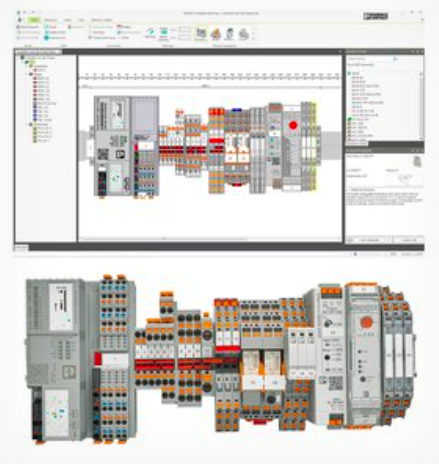

Phoenix Contact offers its PROJECT cabinet design software for the company’s COMPLETE range of cabinet and panel devices, modules and systems, see Figure 2.

This application comprises a straightforward and customisable user interface that is intuitive for the designer. A detailed parts list can be assembled in real-time, and a web order placed when ready. Design data can be exchanged with popular CAE/CAD software, making the process as seamless as possible. With the visual user interface, DIN rail devices and modules are rapidly realised for architects to see how the cabinet layout progresses.

As IIoT and Industry 4.0 innovation continues, new lower power and more energy-efficient devices open up opportunities for saving considerable space in control cabinets and panels. Side-by-side mounting of low power, highly efficient components optimises available space, see Figure 3.

Device manufacturers are also streamlining the dimensions of their devices with the same height profile, saving additional dead space, see Figure 4.

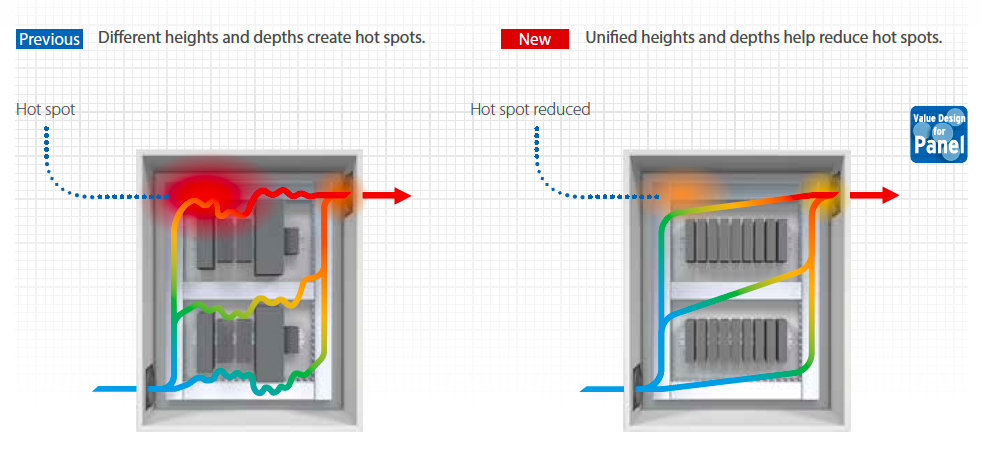

Another significant benefit of devices having the same height is that airflow around the cabinet is less disturbed and uniform, as illustrated in Figure 5. Hot spots are less likely to occur as a result.

Phoenix Contact recommends an approach focusing on five functional areas of cabinet and panel design for success: power reliability, connectivity and switching, automation, networks and I/O, safety, and shop floor productivity. Each topic is then subdivided into relevant categories.

For example, the automation, networks, and I/O subject covers the convergence of networking topologies, remote access, data exchange, and real-time data collection. Figure 6 highlights Phoenix Contact COMPLETE line power supply, Ethernet switches, and wireless LAN DIN Rail mounted devices.

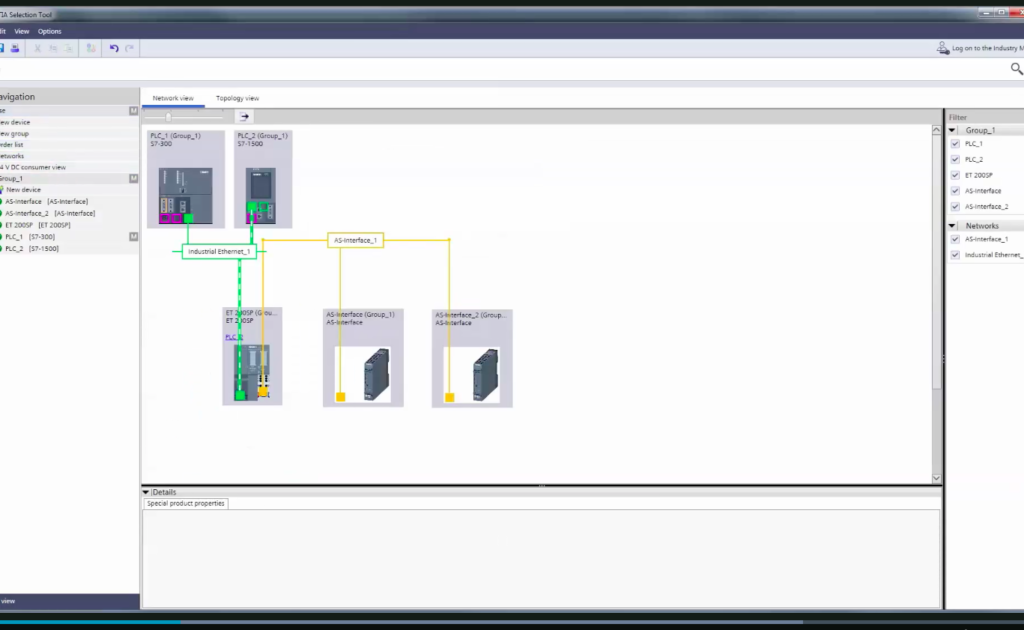

Siemens promotes its TIA (total integrated automation) Selection Tool for cloud or desktop design, see Figure 7. Covering the complete Siemens range of automation components, devices, and systems, the configuration and layout of a cabinet or panel are greatly simplified, and no technical knowledge is required.

Achieve optimal control cabinet performance and space efficiency using a structured design approach

With factory floor space at a premium, optimising control cabinets and panels’ internal layout and design is paramount. Realising operational effectiveness improvements requires deploying more technology, confronting an industrial system architect with multiple design challenges. Adopting a structured approach to selecting, component placement, and documentation aids in simplifying the many tasks. Leading industrial automation system suppliers offer comprehensive 3D visual design, component layout, and configuration resources that significantly ease these complex tasks.