Medical device’s producers are improving both current and growing healthcare markets and are critical in the science industry because they deliver advanced solutions to doctors and patients. Medical device companies need to be focused on technologically advanced solutions, as technology is extremely important in the medical device industry.

The new era of automation and smart factories brought about some changes in medical device manufacture. Digitisation, automated manufacturing and remote solutions are opening doors for a smarter future. A future where medical equipment is less invasive, more efficient, smaller, interconnected and more personalised. Thus still manufacturers have to comply with some regulatory standards to produce safe devices as safety plays a key role in a patient’s health.

Medical manufacturing standards

There is no more essential industry than medical device design and manufacturing where product conformity is critical. Many medical devices are intended to improve individuals’ health as well as identify and treat illnesses. As a result, engineers and manufacturers must assure the safety of the devices they develop. Medical equipment is essential for healthcare because they have a direct influence on public health and quality of life.

Organisations and companies need to follow medical device manufacturing standards that serve patients and healthcare professionals.

Most common standards for Medical Devices

There are several management standards that apply to medical manufacturing devices. The International Organization for Standardization (ISO) establishes global quality and risk management standards for a wide variety of products and enterprises. The most common medical device manufacturing standards include:

- ISO 9001, a general standard for business quality management systems. For medical device manufacturers, ISO 9001 involves management in the quality control process, which helps to save costs, promote responsibility, allow responsible expansion, and simplify regulatory compliance.

- ISO 13485, a standard for quality management systems specifically designed for medical device manufacturers. In the framework of the EU’s Medical Device Regulation, it is now explicitly recognised as a “harmonised” norm. ISO 13485 compliance aids in overall quality control, traceability, process validation, and risk management. Manufacturers who achieve ISO 13485 certification will find it easier to sell their products in worldwide markets by having more optimised procedures and more effective, successful, and risk-averse business operations.

- ISO 45001 outlines requirements for occupational and safety management systems that can be employed in the medical device industry. Used to reduce accident rates and related liability issues.

- ISO 27001, especially important in security, this standard has tools that help to assess and manage cybersecurity risks in organisations. It is built on a set of internationally acknowledged best practices that are neither platform or software package specific.

- ISO 14001, with sustainability being an important term for most industries, especially in production (read more here), implementing its compliance can help medical device manufacturers cut down waste, conserve energy, and reduce carbon footprint.

- ISO 50001, this standard adds to ISO 14001 by providing a structured approach for energy management. It allows medical device makers to cut running costs and increase overall energy efficiency, which improves their reputation and facilitates regulatory compliance.

- IEC 60601 is essential for medical electrical equipment. Although it is a widely accepted standard, it might differ for different countries.

- IEC 62304, the standard covers life cycle criteria for medical software including software embedded in medical equipment, and it is related to both maintenance and development of medical device software.

It isn’t an exhaustive list, there are more standards that may apply depending on the product features and applications. However, given these standards, manufacturers can have an idea what is important to produce well according to regulations. Focusing on digitisation, they can ensure safety of their products as it is taking over medical manufacturing. Are you curious how? Read on.

Digitised and automated medical manufacturing

With the development of technologies and automation, medical facilities become interconnected too. The Industry 4.0 environment is also present in the health sector. With AI and medical robots, machine learning technologies and digitisation, there are opportunities for the medical device industry to produce more at lower prices. Also devices get smaller, less invasive, more efficient and smarter.

According to Fortune Business Insights, the worldwide medical devices market was valued at 425.5 billion US dollars in 2018. The market is expected to reach 612.7 billion US dollars by 2025, with a compound annual growth rate (CAGR) of 5.4%.

Automated medical manufacturing

In the topic of health and safety, there is no space for human error. Also, smaller devices require so much precision and especially in medical applications they have to be produced perfectly. This brings to front automation and Industry 4.0 where manufacturing lines are filled mainly with robotic arms and wireless devices as they are more precise than humans. Read more about wireless solutions for manufacturing lines in this article.

However, optimised and interconnected manufacturing of medical devices is offering lower costs and high-volume automated production. Original equipment manufacturers (OEM) and businesses can also benefit from improved overall quality and productivity and reduced waste.

Gathering data

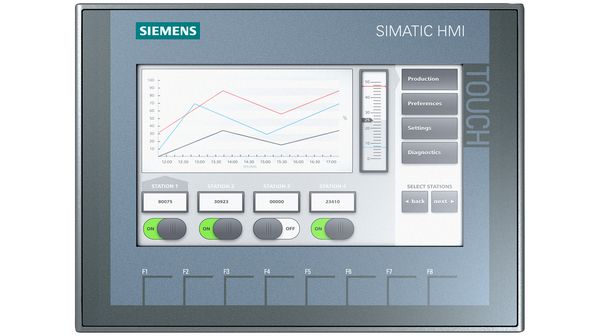

Many organisations are searching for data-driven operations as it is the core of flexible and agile manufacturing techniques. Therefore, devices, like Programmable Logic Controllers (PLC),Human Machine Interfaces (HMI) and robotics are must-have to understand, connect and monitor factory plants. Especially in medical device manufacturing, the optimal operating conditions and quality assurance are key.

We offer the best-in-class PLCs and HMIs from industry leaders like Siemens, Eaton, Omron and more. Read our buyer’s guide on the role of PLCs in industrial IoT or find the perfect HMI for your application.

Siemens’ human machine interface technology, SIMATIC HMI, is designed to handle the increasingly complex processes of your equipment and systems. SIMATIC HMI can suit the customer’s individual human machine interface requirements by utilising open and standardised interfaces in hardware and software, allowing for efficient integration into your automation system.

Smart solutions from smart companies

At Distrelec, we have highly advanced solutions for smart manufacturing. One of our supplier partners is Mitsubishi Electric and its automation products have served as the foundation for a wide range of applications. Some of the applications range from secondary packaging and processing to inspiring innovations in combining robotics with surgical and metaphysical processes. Others are controlling ozone sterilisation for medical instruments, and even manufacturing processes for replacement body parts such as replacement hip joints.

Their innovative system – HealthCam combines visual and infrared video pictures to create a system that can detect heart rate, breathing rate, and body temperature based on minor changes in facial colour and body form. A more sophisticated version will detect blood oxygenation, slip and fall, choking, and aspiration. Watch the video below to find out more.

Schneider Electric’s future-ready platform for hospitals and healthcare institutions – EcoStruxure is designed to promote sustainability, resiliency and hyper-efficiency. Schneider Electric assists its customers in anticipating and managing both regular and exceptional healthcare events.

Robotics

After Industry 4.0, the industrial revolution is ready to welcome Industry 5.0 and many companies are already incorporating new solutions because the 5th industrial revolution focuses on cooperation between humans and robots. It means that there will be more robotic diagnoses and treatments required, necessitating the need for more medical tools and parts designed for use with those systems. One brand that shows how laboratory robot concepts can help hospitals is ABB. The brand clearly states that the medical device industry is about automation, robotics and artificial intelligence.

But robots will not only help in manufacturing and laboratories, but also in hospitals, where they will assist clinical staff and take over tasks such as disinfecting a ward, dispensing medicines or caring for patients.

According to Markets and Marketers, the global medical robots market will be growing.

The primary factors that drive the growth of the robotics market are:

- advantages of robotic-assisted surgery and robot-assisted training in rehabilitation therapy;

- technological advancements in robotic systems;

- reimbursement scenarios;

- increased surgical robot adoption;

- increased funding for medical robot research.

We were already writing about medical robots in the past but the list of robots that have already transformed and are still developing the medical sector is still growing. It is impossible to showcase all but definitely the most industry transforming is the da Vinci Surgical System used for prostatectomies, heart valve repair, and renal and gynecologic surgical procedures.

But robots are also present in different areas of medicine, like mental health. For example, the PARO Therapeutic robot is an interactive gadget similar to an animal. It was created to deliver the advantages of animal therapy without the use of actual animals. PARO is improving quality of life after recovery from surgery or therapy for depression or other mental illnesses. Watch the video below to discover other robotic pets that are helping people with dementia.

Sensors in healthcare

Wearable, implantable, and digestible sensors collect health metrics and vital signs wherever patients or caregivers require them. Sensors are clearly very common in healthcare, especially in AI-devices allowing for monitoring and informing patients about their health. Miniaturisation, customisation, and integration of numerous sensors in a single device enable more data to be collected for more applications.

If you wonder how touch sensors can help with patient care, they are present in many areas of medicine. For example, in minimally invasive surgery (MIS,) incorporating the sense of touch, such sensors can allow doctors to “feel” about inside the human body using the tiniest of initial incisions. They are also present in artery finders that can detect the pressure exerted by the femoral artery when placed against the patient’s skin.

There are plans to implement sensors in prostheses that would send electrical impulse signals delivered to the brain, whenever the prosthesis touches something.

Another innovation where sensors play a role is in diabetic neuropathy. They can also replace the sense of touch that patients with severe types of diabetes lose.

Remote monitoring of patients

Remote monitoring helps patients and healthcare staff to easily track their health without the need for unnecessary hospital and clinical visits or invasive tests. Remote devices deliver data to a computer or mobile device, where it may be analysed, and healthy reading parameters can be set up for automated warnings if the patient gets ill. If you are curious about the interconnection between devices, discover medical applications from Moxa.

Thanks to remote patient monitoring, medical personnel can monitor patients outside of conventional clinics. It also enables patients to keep their freedom, giving better access to healthcare, peace of mind and daily assurance. Remote monitoring may be done using serial Ethernet/Wireless LAN that can connect, for instance, to a patient monitor. Some of these device servers allow for remotely monitoring patients’ physiological signs. We recommend the Wi-Fi serial server from Moxa.

Also the NX series I/O that includes conventional and high-speed digital I/O, analogue I/O gives insights about encoder inputs, pulse outputs, and safety control.

3D printing and prototyping for medical use

3D printing might be crucial for medical applications as it enables custom-made items and devices. 3D printing allows for highly individualised healthcare, among others, the production of personalised products, such as prosthetic limbs, cranial implants, or orthopaedic implants such as dental crowns, hips and knees.

Anatomical models for surgical planning and teaching allow radiologists and surgeons to visualise anomalies and complicated pathologies before operating. Medical personnel may also conduct better patient consultations by displaying how surgery will be performed and discussing the patient’s issues more clearly by developing 3D models of a patient’s anatomy based on a scan. 3D models are also valuable for illustrating and teaching medical students about anomalies such as fractures, tumours, and lesions. Learn more about 3D printing here.

Bioprinting is one of the various forms of 3D printing utilised in the medical device industry and allows for building parts that resemble natural tissues, bones, and blood vessels in the body. 3D bioprinted organs have also been useful in enhancing clinical trials since medication efficacy may be evaluated on bio-printed tissues before being used on humans. 3D printing is also used in medical equipment and personal protective equipment (PPE).

Distrelec have an extensive range of assembled 3D printers and unassembled 3D printer kits. In our webshop you can also find 3D printer filaments from our exclusive RND brand.

The future of medical device manufacturing

Many companies rely on digitisation and automation now. By implementing automated solutions, AI, robotics, 3D printing, sensors and other advanced technologies organisations can monitor and improve the devices that yet work on helping manage patients’ heath and deal with more and more illnesses. In the medical device sector these smart manufacturing solutions assist in digitising their processes, allowing them to shorten time-to-value, enhance efficiency and asset utilisation, and especially build a better product, that is vital in the health sector, and satisfies safety criteria. For medical device manufacturers it is crucial to implement new technologies and ensure the right standards.

Medical disclaimer

All content and information in this article is for informational and educational purposes only, does not constitute medical advice.